Last Updated on 31 May, 2024 by jymachinetech

CBD gummies have taken the health and wellness industry by storm, offering a convenient and enjoyable way to consume cannabidiol. But have you ever wondered how these delightful treats are made?

This article will take you behind the scenes of a CBD gummy factory to explore the fascinating process that transforms raw ingredients into the tasty, beneficial gummies we all love.

Step 1: Sourcing High-Quality Ingredients

The journey of a CBD gummy begins with sourcing. Manufacturers select high-quality CBD isolate or broad-spectrum CBD extract, ensuring it is derived from non-GMO, organically grown hemp plants. Other ingredients like gelatin, fruit flavors, and natural coloring are also carefully chosen for their purity and taste.

Step 2: Preparing the CBD Solution

The CBD extract is first prepared into a solution. This involves dissolving the CBD isolate in a carrier oil, such as coconut oil or MCT oil, which helps to maintain the CBD’s stability and bioavailability. This solution is then tested for potency to ensure it meets the desired concentration levels.

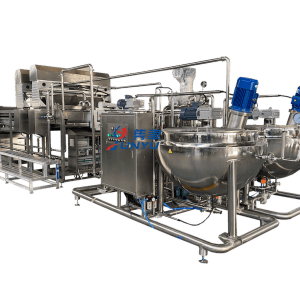

Step 3: Mixing the Gummy Base

Simultaneously, the gummy base is prepared. Gelatin, a key ingredient, is mixed with water and heated to create a liquid solution. Sweeteners, such as sugar or organic sweeteners like stevia, are added, along with natural fruit flavors and colorings to give the gummies their vibrant hues and delicious taste.

Step 4: Combining CBD and Gummy Base

The CBD solution is then carefully combined with the gummy base. This step requires precision to ensure that the CBD is evenly distributed throughout the mixture. The mixture is stirred thoroughly to create a homogeneous blend.

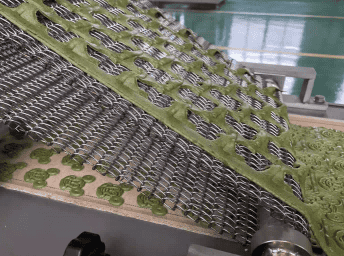

Step 5: Pouring into Molds

The combined mixture is heated to the right temperature and then poured into custom molds that give the gummies their various shapes, such as bears, rings, or other fun forms. The molds are designed to produce gummies of uniform size and shape, ensuring consistency in every batch.

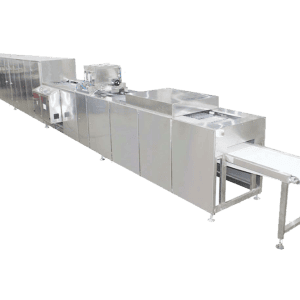

Step 6: Cooling and Setting

The filled molds are placed in a cooling chamber where they are allowed to set and cool down. This process can take several hours, during which the gelatin solidifies and the CBD fully integrates into the gummy.

Step 7: Demolding and Quality Control

Once the gummies have set, they are removed from the molds. Each gummy is inspected for quality, ensuring there are no defects and that they meet the factory’s size and shape standards.

Step 8: Packaging

The gummies are then packaged in airtight containers or resealable bags to maintain their freshness and potency. The packaging also includes labels that provide information about the product, such as the amount of CBD per gummy and any allergen warnings.

Step 9: Rigorous Testing

Before the CBD gummies are shipped out, they undergo rigorous third-party testing to verify their safety, potency, and purity. This ensures that consumers receive a product that is free from contaminants and meets all legal requirements for CBD content.

Step 10: Distribution

Finally, the tested and approved CBD gummies are ready for distribution. They are shipped to retailers, health stores, and online platforms, making their way to consumers who are eager to enjoy the benefits of CBD in a tasty and convenient form.

Conclusion

The creation of CBD gummies is a meticulous process that combines science, technology, and a touch of artistry. From sourcing the finest ingredients to the final packaging, every step is carefully controlled to produce gummies that are not only delicious but also safe and effective. The next time you pop a CBD gummy, you can appreciate the craftsmanship and care that went into making it.

Why Choose Us?

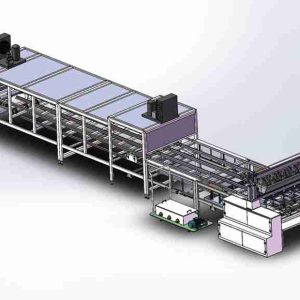

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.