The longevity of a jelly candy making machine is a critical consideration for any confectionery business looking to invest in this type of equipment. The lifespan of such machinery can impact production costs, output quality, and the ability to meet market demands over time.

This comprehensive article delves into the factors that contribute to the lifespan of a jelly candy making machine, providing insights for businesses to make informed decisions.

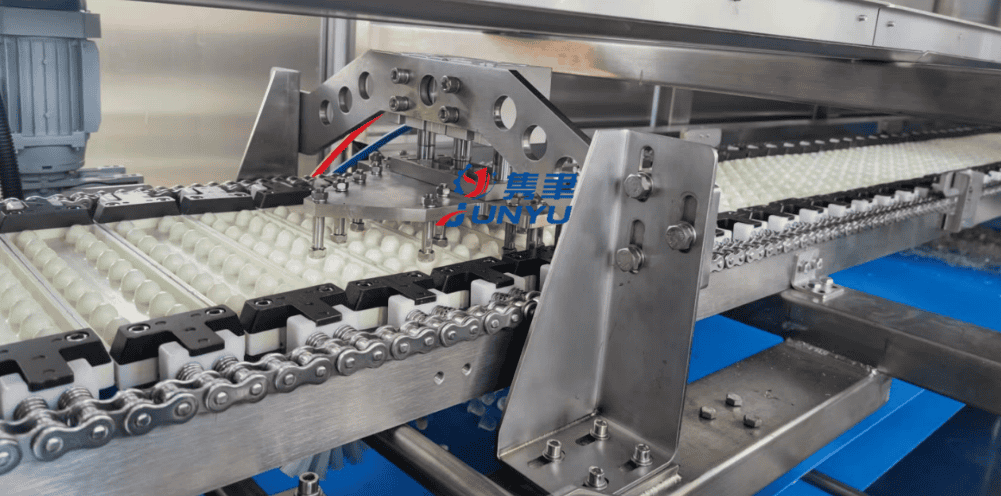

1. Quality of Construction

The foundational aspect of a machine’s lifespan is its construction quality. Machines built with robust, high-grade materials tend to have a longer operational life than those made with cheaper, less durable materials.

2. Manufacturer Reputation

A machine’s lifespan can be indicative of the manufacturer’s reputation for quality and reliability. Established manufacturers with a history of producing long-lasting equipment are often a safer investment.

3. Maintenance and Care

Proper maintenance is crucial in extending the lifespan of a jelly candy making machine. Regular inspections, timely part replacements, and adherence to cleaning schedules can significantly impact how long a machine remains operational.

4. Frequency of Use

The more frequently a machine is used, the more wear and tear it will experience. Machines in high-demand production environments may require more frequent maintenance or part replacements to sustain their lifespan.

5. Operating Conditions

The conditions in which the machine operates can also affect its lifespan. Factors such as temperature, humidity, and cleanliness of the production environment play a role in the durability of the machinery.

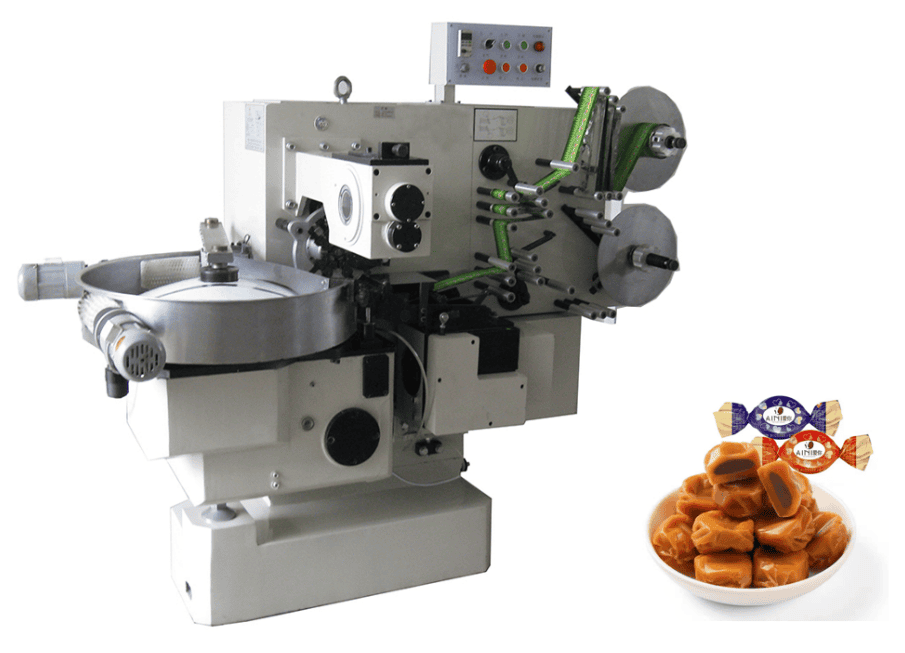

6. Type of Machine

Different types of jelly candy making machines have varying lifespans. For instance, a simple manual press might last longer under light use than a complex, fully automated production line.

7. Material Compatibility

The compatibility of the jelly ingredients with the machine materials is essential. Some ingredients may cause corrosion or wear on certain metals or plastics, necessitating the use of specific materials that can resist such effects.

8. Technological Advancements

As technology advances, older machines may become obsolete, even if they are still functional. Keeping a machine updated with the latest technology can extend its usefulness and lifespan.

9. Upgrades and Retrofits

The ability to upgrade or retrofit a machine with new components or technology can help extend its lifespan by keeping it competitive with newer models.

10. Economical Lifespan

The economic lifespan of a machine is the period over which it remains cost-effective to operate. This can be influenced by factors such as energy efficiency, production output, and the cost of maintenance.

11. Physical Lifespan

The physical lifespan refers to the time a machine can operate without significant breakdowns or repairs. This is often determined by the build quality and the wear of moving parts.

12. Legal and Regulatory Compliance

Regulatory changes may require updates to machinery to meet new safety or production standards, which can affect a machine’s operational lifespan.

13. Market Demand

The demand for certain types of jelly candies may change over time, affecting the need for specific machines. A machine that produces a popular product today may become less relevant tomorrow.

14. Training of Operators

Well-trained operators who understand how to properly use and maintain the machine can help extend its lifespan by reducing the risk of operator error and accidental damage.

15. Repair and Support Services

Access to quality repair and support services can help maintain the lifespan of a machine by providing timely fixes and part replacements.

16. Parts Availability

The availability of replacement parts is crucial for prolonging the life of a machine. Manufacturers that offer long-term support and parts inventory are more likely to keep a machine operational.

17. Energy Efficiency

Energy-efficient machines not only reduce operating costs but can also be designed with components that last longer, contributing to a longer lifespan.

18. Obsolescence and Replacement Cycles

The concept of planned obsolescence in the industry can affect the perceived lifespan of a machine. However, well-built machines can outlast planned replacement cycles.

19. Financial Considerations

The financial implications of owning a jelly candy making machine, including the cost of ownership, maintenance, and potential downtime, all factor into the decision to replace or continue using a machine.

20. Environmental Impact

The environmental impact of manufacturing and operating a jelly candy making machine can influence its lifespan, particularly as more businesses adopt sustainable practices.

Conclusion

The lifespan of a jelly candy making machine is influenced by a multitude of factors, from its initial construction and quality to ongoing maintenance, technological updates, and market demands. By understanding these factors, businesses can make strategic decisions about investing in and maintaining their machinery to ensure a productive and cost-effective confectionery operation. As with any investment, the lifespan of a jelly candy making machine is a balance between functionality, cost, and the ability to adapt to changing industry landscapes.