Last Updated on 24 May, 2024 by jymachinetech

Candy is a universal treat that brings joy and a touch of sweetness to people’s lives across the globe. Yet, the enjoyment of these delights hinges on the assurance of their safety. This article, “Snack Safely: The Role of Food Security in Candy Manufacturing,” explores the critical measures candy manufacturers implement to ensure that the confections we savor are not only delightful but also secure and safe for consumption.

1. Understanding Food Security in Candy Production:

Food security in candy production goes beyond the mere absence of biological, chemical, and physical hazards. It also involves the accessibility, sustainability, and quality of the candy supply. Manufacturers must begin with high-quality ingredients and adhere to strict safety standards throughout the entire production process.

2. The Importance of Raw Material Sourcing:

The foundation of food security starts with the selection and sourcing of raw materials. Manufacturers must ensure that ingredients such as sugar, cocoa, and flavorings meet stringent safety and quality benchmarks. This often involves close collaboration with suppliers and regular audits to verify compliance with food safety standards.

3. Implementing Good Manufacturing Practices (GMP):

Adherence to Good Manufacturing Practices is fundamental to food security in candy production. GMP encompasses the overall layout of the processing facility, equipment maintenance, and personnel hygiene practices. These practices help prevent contamination and ensure a suitable manufacturing environment for safe food production.

4. Hazard Analysis and Critical Control Points (HACCP):

HACCP is a systematic approach to food safety that identifies potential hazards in the production process and establishes controls to manage these risks. Candy manufacturers use HACCP to monitor critical control points, such as cooking temperatures and storage conditions, ensuring the safe production of candies.

5. Advanced Quality Control Technologies:

State-of-the-art candy production lines incorporate advanced quality control technologies to detect and prevent issues before they affect the final product. Metal detectors, X-ray machines for foreign object detection, and sophisticated software for tracking and tracing products throughout the supply chain are vital in maintaining food security.

6. Training and Education of Personnel:

The workforce is the first line of defense in food security. Regular training and education for all employees on food safety principles, hygiene practices, and the significance of their role in candy production are essential. A knowledgeable and well-trained staff is better equipped to handle food safety concerns and uphold a secure production line.

7. Regulatory Compliance and Certifications:

Compliance with food safety regulations and obtaining relevant certifications such as ISO 22000 and FSSC 22000 not only validates a manufacturer’s commitment to food security but also reassures consumers and trading partners that the candies produced meet international safety standards.

8. Continuous Improvement and Innovation:

The candy manufacturing industry must continuously improve and innovate its production processes to address new food safety challenges and evolving consumer expectations. This may include adopting new technologies, refining existing processes, or developing new products while maintaining food safety.

Conclusion:

As we indulge in our favorite candies, it’s comforting to know that a robust system is in place to ensure our safety. From the fields where ingredients are grown to the factories where candies are crafted, the role of food security in candy manufacturing is paramount. By adhering to stringent safety protocols, investing in advanced technologies, and fostering a culture of continuous improvement, candy manufacturers worldwide are dedicated to producing sweets that we can enjoy with confidence.

Author’s Note: This article aims to highlight the critical measures taken by the candy manufacturing industry to ensure food security, reminding us that the joy of snacking is deeply intertwined with the assurance of safety and quality.

Why Choose Us?

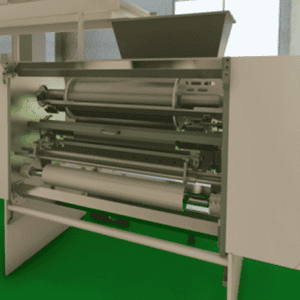

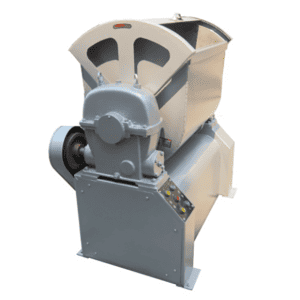

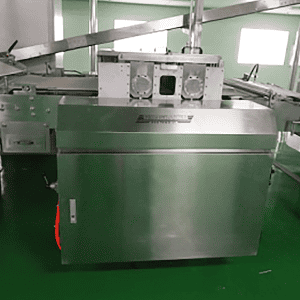

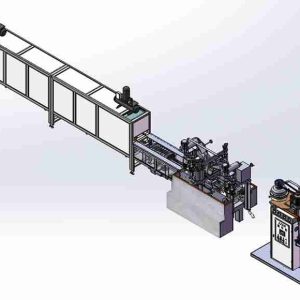

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.