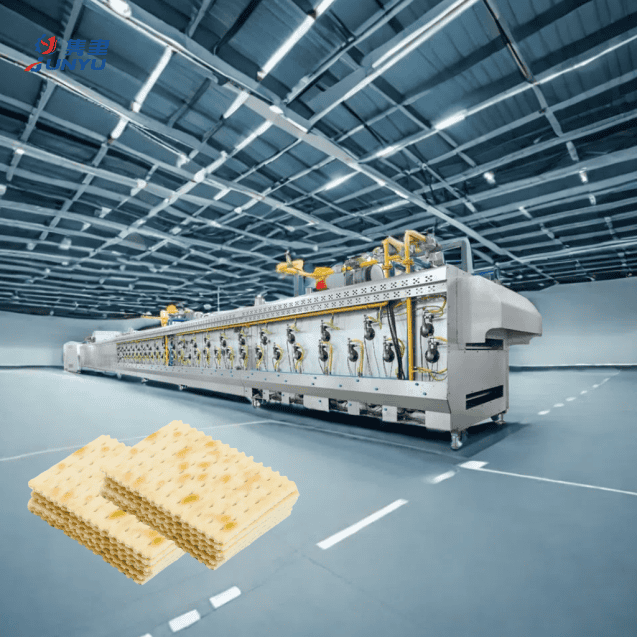

Fully Automatic Hard and Soft Biscuit/Cracker Machine

Capacity: 100-1500kgs per hour

Oven Type: Gas / Electric / Diesel Oil

Automation: Fully automated from mixing to packing

Warranty: One Year Warranty & Lifetime After-Sales Support

Control System: SIEMENS PLC with Remote Control

Overseas Installation: Expert Engineers for Installation & Support

The Fully Automatic Hard and Soft Biscuit/Cracker Machine is an advanced production line that ensures exceptional efficiency, consistent quality, and versatility for biscuit manufacturers. Capable of producing up to 1500 kg per hour, this fully automated system streamlines the entire biscuit-making process, from mixing ingredients to final product packaging.

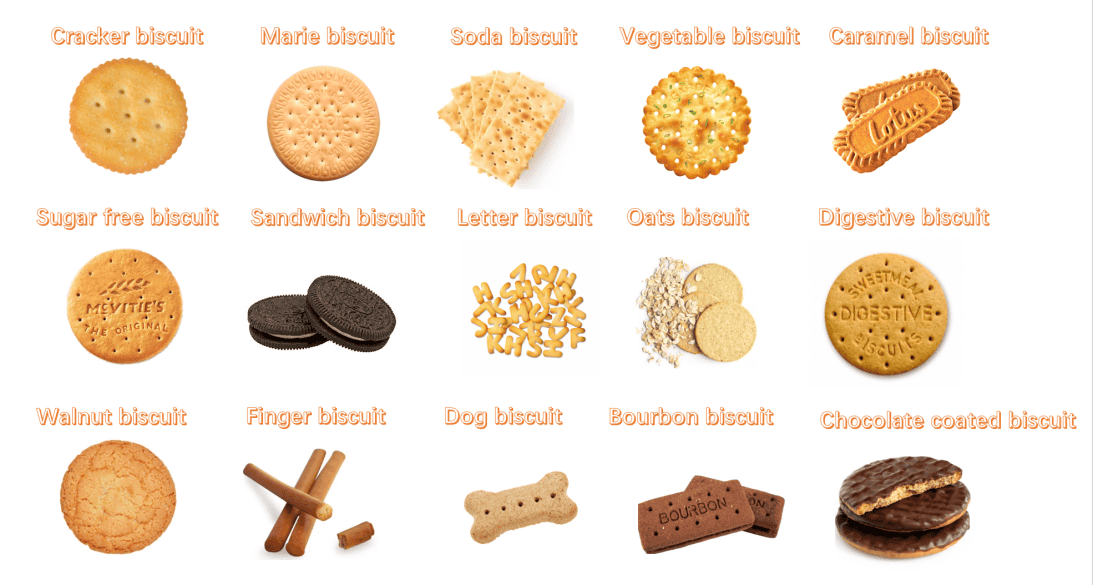

Versatile & Customizable Production

This machine can handle a wide variety of biscuit types, such as crisp biscuits, soft biscuits, sandwich biscuits, soda biscuits, animal biscuits, finger biscuits, and more. By simply adjusting the molds and formulas, you can easily switch between different products, making it an ideal choice for companies looking to diversify their product offerings.

Key Features:

Durable & Reliable

Made from high-quality materials, this biscuit/cracker machine is built for durability and long-term performance. The robust construction ensures that the machine operates smoothly even under high demand, providing you with a reliable solution for large-scale production.

End-to-End Efficiency

The entire production line is designed to maximize efficiency, reducing downtime and enhancing production capacity. From the mixing stage to baking, cooling, and final packaging, every component works seamlessly together to provide a high-output and high-quality solution for your biscuit-making needs.

Whether you’re producing a variety of hard biscuits, soft biscuits, or crackers, this fully automatic machine delivers consistent results with ease, meeting the needs of both large-scale manufacturers and businesses looking to expand their product lines.

| Model | 600 | 800 | 1000 | 1200 | 1500 |

| Production capacity(kg/h) | 500 | 700 | 1000 | 1200 | 1500 |

| Total length(mm) | 85500 | 92500 | 125000 | 150000 | 170000 |

| Baking temp(℃) | 190-240 | 190-240 | 190-240 | 190-240 | 190-240 |

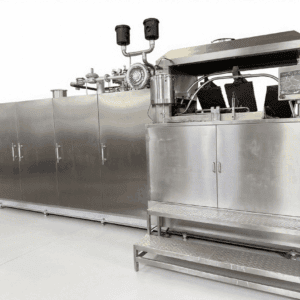

The Horizontal Dough Mixer is an essential component in the biscuit production line, designed to deliver optimal results in dough preparation. This advanced mixer is engineered to knead, calendar, and fold the dough during the mixing process, ensuring a consistent and high-quality dough texture.

After the dough undergoes these stages, it emerges with a smooth surface and superior elasticity, toughness, and extensibility—key attributes for producing biscuits with the perfect texture. The mixer’s design guarantees that the dough is evenly processed, which is crucial for achieving uniform quality in the final product.

Versatile for Different Biscuit Types

The Horizontal Dough Mixer is highly adaptable, making it suitable for both tough biscuits and crispy biscuits. Its versatility allows manufacturers to create a wide range of biscuit textures, meeting the diverse demands of the market while maintaining high production standards.

This mixer is built for efficiency, durability, and consistency, making it an indispensable tool for biscuit manufacturers looking to streamline their dough preparation process and ensure superior product quality every time.

The Dough Laminator works in synergy with the Roller Sheet Forming Machine, playing a crucial role in the production of hard biscuits. This advanced laminating system is designed to create multiple layers in the dough, improving both its texture and structure.

For tough biscuits, the dough laminator is particularly advantageous, as it enhances both quality and grade, resulting in biscuits with improved uniformity and texture. The laminating process helps achieve the ideal balance of crispness and tenderness, giving the final product a premium feel and taste.

Additionally, this machine is essential for producing fermented crackers, as the lamination process ensures proper fermentation and optimal dough development. By carefully layering the dough, the laminator ensures that the crackers have a light, airy texture with a consistent bite, making it an indispensable piece of equipment in high-quality biscuit production.

1. Machine designed specially for different biscuit

2. Variety molds to be selected for all shapes biscuits

The oven system offers flexibility with three types of heating options: Gas, Electric, and Diesel. Depending on your specific product requirements, you can choose the most suitable energy source to optimize production costs and efficiency. Each type of oven is designed to deliver consistent and even heat distribution, ensuring superior baking results for various types of biscuits.

These ovens feature multiple independent temperature zones, allowing for precise control over the baking process. Each zone can be individually adjusted to meet the specific needs of different biscuit varieties, ensuring uniform cooking and the perfect texture every time. Whether you’re baking hard, soft, or specialized biscuits, the customizable temperature settings ensure that each batch meets the highest quality standards.