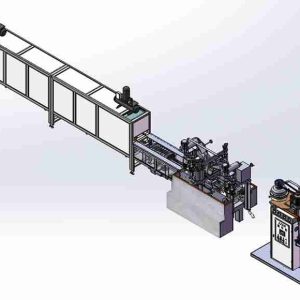

Welcome to the world of wafer production, where innovation meets efficiency! Our fully automated wafer production line is designed to revolutionize the way you manufacture wafers. With its reliable linear performance, compact structure, and small footprint, this production line offers high output, low energy consumption, easy maintenance, and simple operation. Whether you are a small-scale producer or a large-scale manufacturer, our wafer production line is tailored to meet your needs and exceed your expectations.

What sets our wafer production line apart is its unique ability to create wafers with a crisp and light texture that blends perfectly with soft cream or chocolate. Unlike other biscuits, our wafers are produced from a very fluid batter that is baked between heavy hot plates, resulting in thin sheets that offer a delightful eating experience. Imagine the satisfaction of biting into a wafer that melts in your mouth, leaving a lingering taste of pure indulgence. This is what our production line delivers, time and time again.

Machine Principle

At the heart of our wafer production line is a sophisticated machine principle that ensures every wafer is produced to perfection. The process begins with high-speed mixing of flour and oil to create a rich fluid batter. Our state-of-the-art Junyu machine then doses the batter onto the baking plates, forming a full wafer sheet. This sheet is transferred to the cream coating machine, where layers of cream can be applied according to your specifications. After cooling, the creamed wafer sheet is cut into different sizes by cross and vertical cutters, ready to be packed or enrobed with a chocolate coating.

Our production line is designed to be highly automated and easy to control, allowing you to focus on other aspects of your business while we take care of the manufacturing process. With advanced technology and precise engineering, we ensure that every wafer produced meets the highest standards of quality and consistency.

Models and Specifications

| 型号Model |

JYW-27 |

JYW-39 |

JYW-45 |

JYW-51 |

JYW-63 |

JYW-75 |

| 产量Capacity(kg/24h) |

2500 |

3500 |

4000 |

5000 |

6000 |

7000 |

| 电炉Electric Oven |

整机功率

Whole line power ( kW ) |

120 |

160 |

180 |

200 |

250 |

290 |

| 烤板功率Heating Plate Power (kW) |

86 |

124 |

144 |

163 |

201 |

245 |

| 气炉Gas Oven |

燃气消耗量

Gas Consumption(kg/h) |

13 |

19 |

23 |

27 |

32 |

37 |

| 功率 Power(kW) |

2.2 |

2.2 |

3.5 |

3.5 |

3.5 |

4.5 |

外形长度

External Length (mm) |

5930 |

8330 |

9470 |

10610 |

12890 |

15290 |

JYW-27: The Perfect Starter Model

The JYW-27 is the ideal choice for small to medium-sized businesses looking to enter the wafer market. With a capacity of 2500 kg per 24 hours, this model offers a perfect balance between output and energy efficiency. Its compact design and small footprint make it easy to integrate into existing production facilities without requiring extensive modifications. The JYW-27 is equipped with all the essential features of our production line, ensuring that you can produce high-quality wafers from day one.

JYW-39: Scaling Up with Confidence

As your business grows, the JYW-39 is the perfect model to help you scale up your production. With a capacity of 3500 kg per 24 hours, this model offers increased output while maintaining energy efficiency. The JYW-39 is designed to handle larger production volumes without compromising on quality or performance. Its advanced features and reliable operation make it an excellent choice for businesses looking to expand their wafer production capabilities.

JYW-45: Meeting the Demand

The JYW-45 is designed to meet the increasing demand for wafers in the market. With a capacity of 4000 kg per 24 hours, this model offers a significant boost in production output. Its robust design and advanced technology ensure that you can produce wafers at a faster rate without sacrificing quality. The JYW-45 is equipped with powerful heating plates and efficient gas consumption, making it an energy-efficient solution for your production needs.

JYW-51: High-Volume Production

For businesses with high-volume production requirements, the JYW-51 is the ideal choice. With a capacity of 5000 kg per 24 hours, this model is designed to handle large-scale production with ease. Its powerful heating plates and efficient gas consumption ensure that you can produce wafers at a rapid pace without compromising on quality. The JYW-51 is equipped with advanced features and reliable operation, making it a top-of-the-line solution for your wafer production needs.

JYW-63: Maximizing Output

The JYW-63 is designed to maximize your wafer production output. With a capacity of 6000 kg per 24 hours, this model offers the highest production volume in our range. Its powerful heating plates and efficient gas consumption ensure that you can produce wafers at an unprecedented rate. The JYW-63 is equipped with advanced features and reliable operation, making it the ultimate solution for businesses looking to dominate the wafer market.

JYW-75: The Ultimate Production Line

For those who demand the highest level of production efficiency and output, the JYW-75 is the ultimate wafer production line. With a capacity of 7000 kg per 24 hours, this model is designed to meet the most demanding production requirements. Its powerful heating plates and efficient gas consumption ensure that you can produce wafers at an unparalleled rate. The JYW-75 is equipped with the latest technology and advanced features, making it the pinnacle of wafer production solutions.

Components and Features

Dough Mixer: Precision Mixing for Consistent Quality

The dough mixer is the foundation of our wafer production line. It is designed to thoroughly mix sugar, butter, and other ingredients according to the technological prescription, ensuring consistent quality in every batch. The mixer features a filtering system to remove any impurities, guaranteeing that only the finest ingredients are used in the production process.

Our dough mixer is built with durability and reliability in mind. The machine frame is made of steel that meets international standards, providing a sturdy and robust structure. The cover is made of imported 304 stainless steel with a thickness of 3mm, ensuring long-lasting performance and easy maintenance. The cream barrel also uses imported 304 stainless steel with a thickness of 3mm, further enhancing the quality and durability of the mixer.

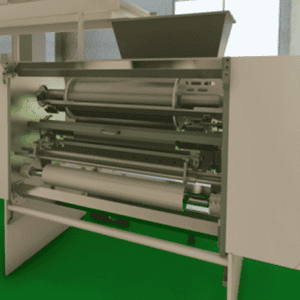

Wafer Baking Oven: The Heart of the Production Line

The wafer baking oven is the centerpiece of our automated production line. It consists of a baking oven, cooling tower, cream spreading machine, cooling cabinet, packing machine, batter mixer, cream mixer, and wafer smash machine. Each component is designed to work seamlessly together, ensuring a smooth and efficient production process.

The cooling tower plays a crucial role in cooling down the freshly baked wafer sheets to prevent deformation. This ensures that every wafer maintains its perfect shape and texture. The cream spreading machine applies cream layers automatically and regularly before the wafer block is sent to the conveying belt. This advanced feature allows for precise and consistent cream application, enhancing the final product’s taste and appearance.

Conveyor: Smooth and Efficient Movement

The conveyor system is designed to move the wafer sheets smoothly and efficiently through the production line. It ensures that every wafer is transported with care, maintaining its quality and integrity throughout the entire process. The conveyor’s slow and steady movement allows for proper cooling and prevents any damage to the delicate wafer sheets.

Cooling Tower: Ensuring Perfect Cooling

The cooling tower is an essential component of our wafer production line. It runs slowly to ensure proper cooling and prevent any deformation of the wafer sheets. By maintaining a consistent temperature, the cooling tower ensures that every wafer retains its perfect shape and texture. This attention to detail is what sets our production line apart and guarantees high-quality wafers every time.

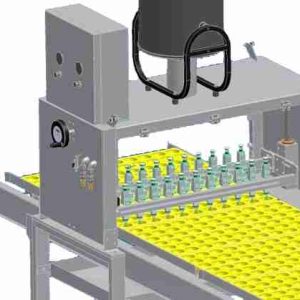

Sheet Collecting Machine: Efficient Gathering

The sheet collecting machine gathers the wafer sheets after they have been baked and cooled. This machine is designed to work efficiently and accurately, ensuring that every wafer sheet is collected without any damage. The sheet collecting machine is an essential component of our production line, contributing to the overall efficiency and quality of the production process.

Cream Spreading Machine: Precision Application

The cream spreading machine is equipped with advanced technology to apply cream or chocolate layers to the wafer sheets. It features a cooling system with a cooling compressor to reduce cooling time and improve efficiency. The machine runs slowly to ensure proper cooling and conveyance of the wafer block, preventing any deformation or damage.

The cream spreading machine offers optional and adjustable cutting layers, allowing you to customize the thickness of the cream or chocolate layers according to your preferences. The cutting channel features a glass visual window and safety shield, ensuring a clear view of the production process while maintaining safety standards. This advanced machine ensures that every wafer is coated with a perfect layer of cream or chocolate, enhancing the final product’s taste and appearance.

Cutting Machine: Precision Cutting with Ease

The cutting machine is equipped with one vertical and one horizontal wire cutting machine that can cut the cooled wafer block into small pieces in seconds. It uses PLC program control automation, ensuring precise and consistent cuts every time. The cutting machine is designed to work seamlessly with cutting conveyors, making the entire process smooth and efficient.

The cutting layer is optional and adjustable, allowing you to customize the size and shape of the wafer pieces according to your specifications. The cutting channel features a glass visual window and safety shield, ensuring a clear view of the production process while maintaining safety standards. This advanced cutting machine ensures that every wafer piece is cut with precision and care, ready to be packed or enrobed with a chocolate coating.

Mixer for Cream or Chocolate: Consistent Quality

The mixer for cream or chocolate is designed to thoroughly mix sugar, butter, and other ingredients according to the technological prescription. It ensures consistent quality and texture in every batch, guaranteeing that the final product meets the highest standards. This advanced mixer is an essential component of our production line, contributing to the overall quality and taste of the wafers.

Smash Machine for Recycle: Reducing Waste and Saving Costs

The smash machine for recycle is a supplementary equipment used for waste recycling. It helps reduce material loss and save costs by reprocessing waste materials. This innovative machine ensures that every bit of material is utilized, minimizing waste and maximizing efficiency. The smash machine for recycle is an excellent addition to our production line, contributing to our commitment to sustainability and cost-effectiveness.

Chocolate Coating Machine with Cooling Tunnel: Adding the Finishing Touch

The chocolate coating machine with cooling tunnel is used to create high-quality pure chocolate or composite chocolate coatings. It can be fixed on the production line or used separately to wrap any product with a chocolate coating. This advanced machine ensures a smooth and even chocolate layer, enhancing the final product’s appearance and taste.

The cooling tunnel is designed to cool down the chocolate-coated wafers quickly and efficiently, ensuring that the chocolate sets perfectly. This attention to detail is what sets our production line apart and guarantees high-quality wafers every time. The chocolate coating machine with cooling tunnel is the perfect finishing touch to our wafer production process, ensuring that every wafer is coated with a perfect layer of chocolate.

Why Choose Our Wafer Production Line?

Our wafer production line offers a comprehensive solution for manufacturing high-quality wafers with efficiency and precision. Here are just a few reasons why you should choose our production line:

High-Quality Production

Our production line is designed to produce wafers with a crisp and light texture that blends perfectly with soft cream or chocolate. Every wafer is produced to perfection, ensuring a delightful eating experience for your customers.

Advanced Technology

Our production line features the latest technology and advanced features, ensuring efficient and precise manufacturing. From the dough mixer to the chocolate coating machine, every component is designed to work seamlessly together, guaranteeing high-quality wafers every time.

Customizable Options

Our production line offers customizable options to meet your specific needs. Whether you want to adjust the cream or chocolate layer thickness or customize the size and shape of the wafer pieces, our production line can be tailored to your preferences.

Energy Efficiency

Our production line is designed to be energy-efficient, reducing your operating costs and environmental impact. With advanced technology and precise engineering, we ensure that every component operates at peak efficiency, saving you money in the long run.

Easy Maintenance

Our production line is designed to be easy to maintain, ensuring minimal downtime and maximum productivity. With durable materials and reliable components, our production line is built to last. Our easy-to-use maintenance features make it simple to keep your production line running smoothly.

Excellent Customer Support

We are committed to providing excellent customer support to ensure your satisfaction. Our team of experts is always available to assist you with any questions or concerns you may have. From installation to maintenance, we are here to support you every step of the way.

Conclusion

Our wafer production line is the ultimate solution for high-quality wafer manufacturing. With its reliable performance, advanced technology, and customizable options, our production line is designed to meet your needs and exceed your expectations. Whether you are a small-scale producer or a large-scale manufacturer, our wafer production line offers a comprehensive solution for your production needs.

Don’t miss out on this opportunity to revolutionize your wafer production process. Contact us today to learn more about our wafer production line and how it can benefit your business. We look forward to helping you achieve your production goals and take your business to new heights.