Our automatic cake production line is designed for efficiency and quality, offering high automation, stable operation, and large baking volume. It produces delicious cakes with a good taste and long shelf life, suitable for various types of cakes such as core-filled egg yolk pie cakes, cupcakes, and sliced cakes. With customizable mold plates, you can create colorful cakes in different shapes. Below is an overview of the production flow and the advantages of our cake production line.

Advantages of the Cake Production Line

- High-Quality Materials : Made with SUS 304 stainless steel, our machines meet health and safety standards, ensuring the production of safe and hygienic cakes.

- Automatic Control : Equipped with a PLC system, the cake production line allows for precise automation with minimal manual input, boosting efficiency and accuracy.

- Cost-Effective : Our machines offer high quality at competitive prices, providing excellent value for your investment.

- Certifications : Our production line is CE and ISO certified, ensuring compliance with international quality and safety standards.

- Safety Features : Equipped with visible safety covers, our machines ensure a safe working environment for your staff.

- Self-Cleaning Function : After production ends, the machines can clean themselves, saving time and labor.

- Easy Installation and Maintenance : The cake production line is designed for simple installation and easy maintenance, reducing downtime and operational costs.

- Experienced Engineers : With over 20 engineers experienced in overseas installations, we provide reliable support for setting up and optimizing your production line.

- Customized Formulas : We offer tailored formulas for each customer, ensuring that your cakes meet your specific quality and taste standards.

- Quick Lead Time : We understand the importance of timely delivery and strive to provide quick lead times to keep your production on schedule.

- 24/7 Technical Support : Our technology support team is available online within 24 hours to assist you with any technical issues.

- Annual Maintenance : We offer annual maintenance services to keep your production line running smoothly and efficiently.

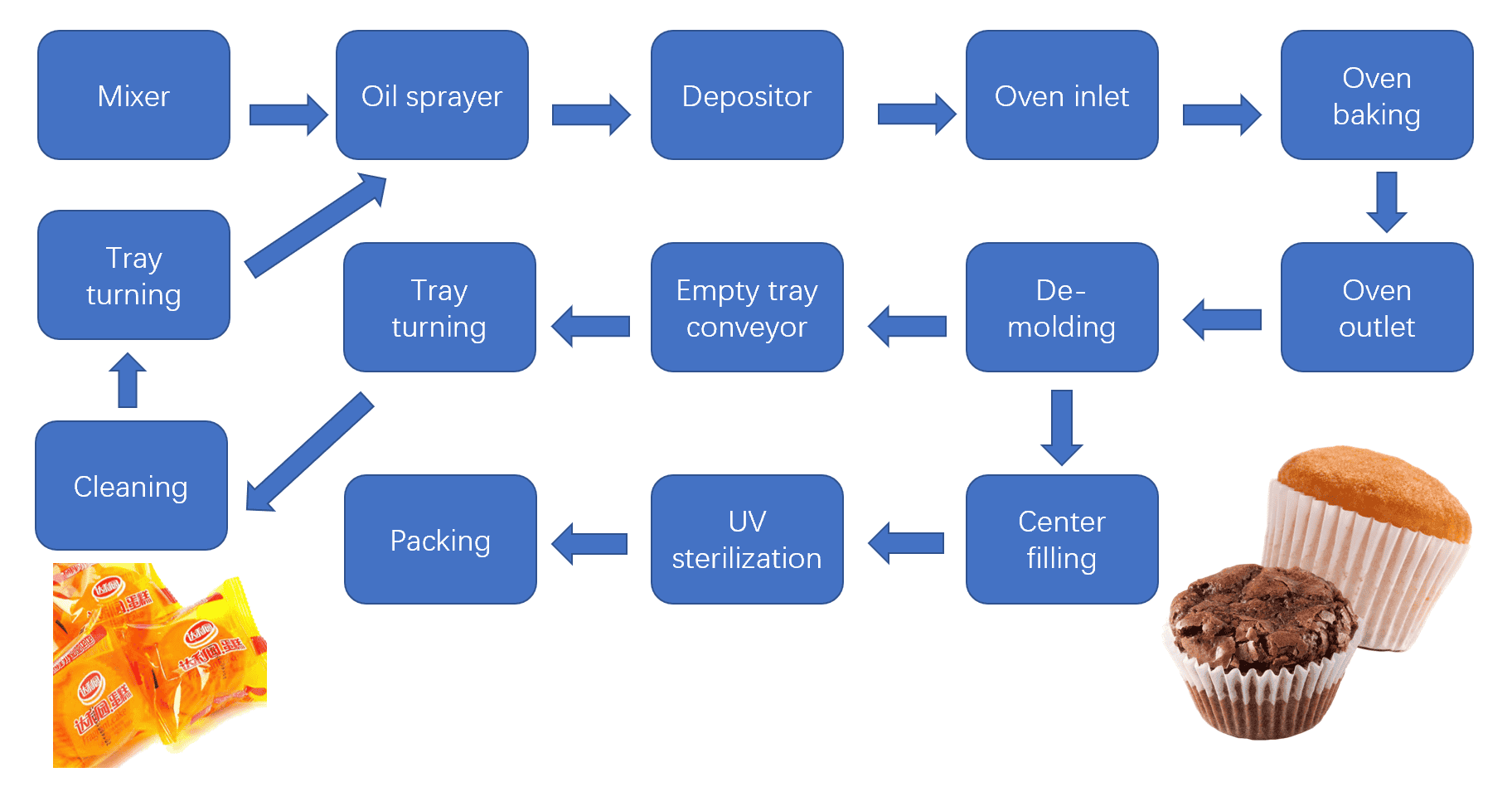

Cake production line – Production Flow Overview

- Mixing : Ingredients are mixed to form the cake batter.

- Depositing : The batter is deposited into molds according to the desired cake shape.

- Baking : Molds are transferred into the oven within the cake production line, ensuring even baking and a perfect texture.

- Cooling : The baked cakes are cooled to the optimal temperature.

- Filling (if applicable) : For core-filled cakes, the filling is added at this stage.

- Demolding : The cakes are removed from the molds.

- Packaging : The finished cakes are packaged for distribution.

Why Choose Our Cake Production Line?

- Innovative Design : Our production line is designed with the latest technology to ensure efficiency and high-quality output.

- Customization : We offer customizable solutions to meet your specific production needs, from different cake shapes to unique flavor profiles.

- Global Service : We offer worldwide installation and technical support, ensuring your cake production line runs smoothly wherever you are.

- Sustainability : We are committed to sustainable practices, using energy-efficient technologies and eco-friendly materials in our production lines.

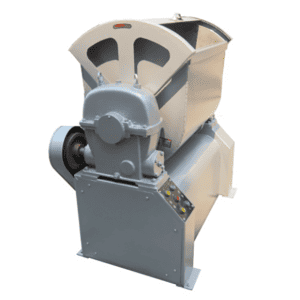

Mixing system

This cake production line machine is the necessary equipment for the cake production, including the raw ingredients, conveying. With this machine, the cake will be softer.

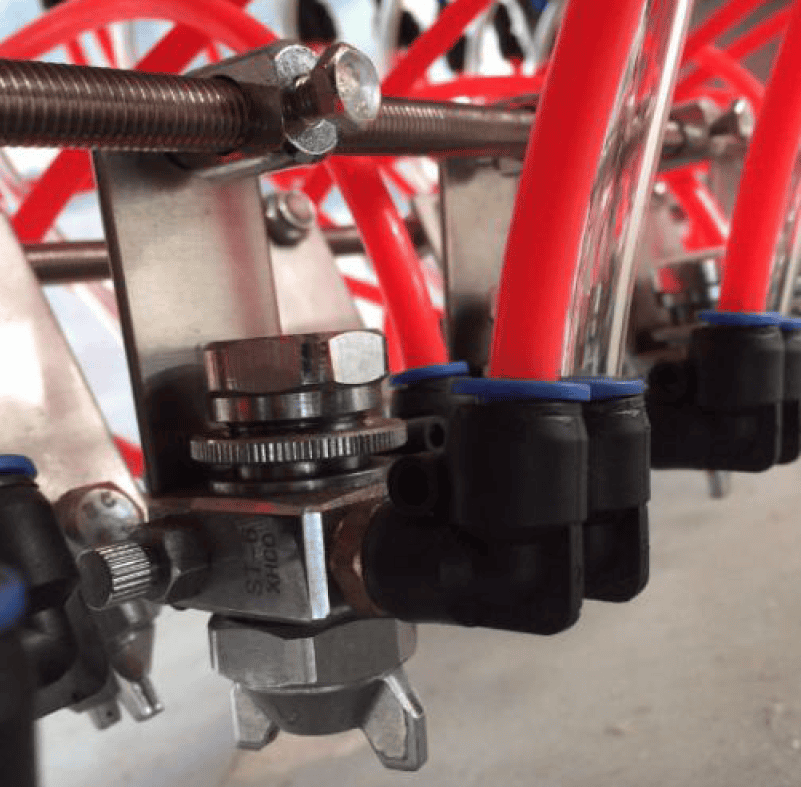

Oil spraying system

The oil spraying system can be separately controlled. After spraying oil, the cake baking tray is easy to demold.

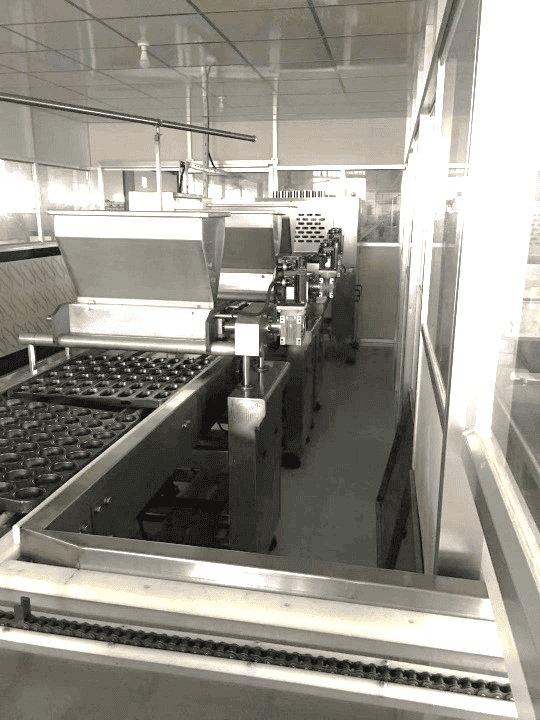

Depositing machine

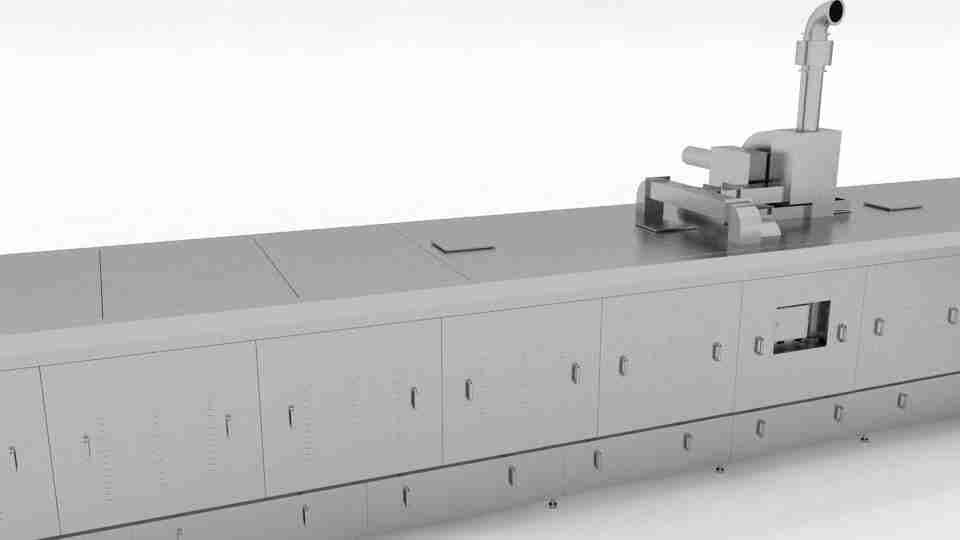

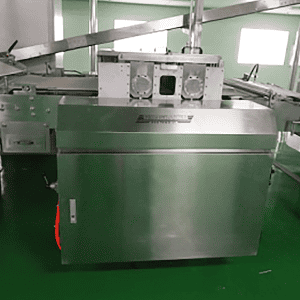

Baking oven

Our cake production line features a hot air circulation oven, a novel baking furnace developed by our factory based on imported equipment. This oven takes the advanced heating methods of gas burning and the hot air circulation. It’s divided into five areas: “front, middle, back, top and bottom”. After the temperature is set, it automatically controlled by the motor through the butterfly valve. The temperature from the top and bottom through the air channel pass to hearth to bake the food. It has the advantage of fast heating, temperature stabilization, small change, automatically control the temperature. All its advantage makes the food to taste more soft and the color more bright.

Demolding system

In Our cake production line – cakes are vacuumed out of the mold through the machine when they are after baking. It uses the cylinder to move up and down, front and back and pressure to suck cakes, then cakes are conveyed to the belt with good shape.

Tray turning

This function of the machine is designed for trays when they need to be washed. After the cakes are sucked out and conveyed onto the cooling line, the empty pan will be conveyed back into the cake production line, turned over, and then automatically washed by air.

Cooling conveyor and UV sterilization

The cooling line is the last process before the packing. The cooling and UV sterilization line has two advantages:

- it helps the cake to be packed at a perfect temperature;

- UV sterilization can make sure the cakes are from non-hygiene elements.

Packaging machine

Cake sample

According to your finished cake size, our machine could be acceptable for different cakes.

More RFQ about cake production line

Q: What is a cake product?

A: A cake product is a delectable dessert crafted from a mixture of ingredients—primarily flour, sugar, eggs, and butter—combined with various flavorings and leavening agents. It is typically baked to achieve a soft, spongy texture. Cakes vary widely, from simple sponge cakes to elaborate, multi-layered celebration cakes, all of which can be produced using a modern cake production line.

Q: Can the machine make biscuits too?

A: While our machine specializes in the production of cakes, it is designed specifically for that purpose. Biscuits require a different process and machinery, as they involve distinct forming and baking techniques. If you’re interested in producing biscuits, we recommend exploring machines that are tailored for biscuit manufacturing.

Q: How many pieces can the machine make per hour?

A: Production capacity varies based on the size and type of cake. Depending on the configuration of your cake production line, output can range significantly. For accurate figures tailored to your production goals, please contact our sales team.

Q: Can you offer the formula?

A: Absolutely, we understand that a key component of cake production is the recipe. Upon purchase, we provide our customers with a comprehensive formula guide that includes a variety of cake recipes. This ensures that you can produce delicious and consistent cake products with your new machine.

Q: If I order now, how long will it take for me to receive the machine?

A: The delivery time for our smallest cake machine typically ranges from 20 to 40 days. However, lead times can vary based on several factors, including the specific model, customization options, and current order volume. For the most accurate and up-to-date lead time information, we recommend reaching out to our customer service team before placing your order.

Q: How is the machine maintained?

A: Proper maintenance is essential for long-term reliability. Each cake production line includes a detailed user manual outlining operations, key components, and a suggested maintenance schedule to help keep your equipment running smoothly.

Why Buy Machines from Us – Manufacturer

Real Factory, Not a Trading Company

- Factory Tour Invitation : We invite you to visit our factory and witness our manufacturing process firsthand. See the state-of-the-art facilities and meet the dedicated team behind our high-quality machines. Experience the transparency and integrity that comes with dealing directly with a manufacturer.

Professional Expertise

- Decades of Experience : With over 40 years of machine manufacturing experience, our factory stands as a testament to excellence and innovation in the industry.

- Skilled Design Team : Our team includes 12 highly skilled drawing designers who ensure every machine is meticulously planned and tailored to meet specific requirements.

- Expert Engineers : We have 20 professional engineers on staff, ready to provide technical support and assistance anytime and anywhere. Their expertise ensures that you receive not only a machine but a comprehensive solution.

Reliability

- Robust Workforce : Our modern factory employs over 200 skilled workers who are committed to producing the highest quality machines.

- Strict Quality Control : We maintain a rigorous quality control system to ensure that every machine meets our exacting standards. Our commitment to quality is unwavering, ensuring reliability and performance in every product.

- Advanced Manufacturing : Utilizing advanced German-standard CNC machining centers, we achieve precision and consistency in every detail of each machine. This technology enables us to handle complex processes with accuracy, resulting in superior products.

- Custom Solutions : Our professional engineering team works closely with you to develop the best plan according to your specific requirements. Whether you need a customized layout or a unique machine design, we deliver tailored solutions.

High-Quality Machines

- GMP Standard Factory : All our machines including: cake production line are manufactured in a GMP-standard facility, ensuring they meet stringent quality and safety standards.

- Precision Manufacturing : We operate CNC centers that guarantee the precision and accuracy of our machines. This technology allows us to produce components that fit perfectly and operate seamlessly.

- Superior Materials : Our machines are constructed using SUS304 stainless steel, known for its durability and resistance to corrosion. The sandblasting surface coating adds an extra layer of protection and enhances the aesthetic appeal.

Comprehensive Services

- Factory Layout Design : We offer expert assistance in designing the optimal layout for your factory, maximizing efficiency and workflow.

- 3D Design & Project Planning : Our 3D design services provide a detailed visualization of your project, ensuring that every aspect is planned meticulously before implementation.

- Customized Shape Design : We understand that each product is unique, and we offer customized shape design services to meet your specific needs. Our designers work closely with you to create the perfect molds and shapes for your products, just as we’ve done in our cake production line.

- Product Formula Development : Our expertise extends beyond machinery to include product formula development. We help you create and refine formulas to ensure your products meet the highest standards of quality and taste.

Why Choose Us?

- Overseas Service Team : We have a dedicated service team ready to assist you globally, ensuring that you receive support no matter where you are located.

- Local Service in North America : Our local service in North America ensures quick and efficient support, minimizing downtime and maximizing productivity.

- Annual Machine Maintenance : We provide annual maintenance services to keep your machines running smoothly and efficiently.

- 24/7 Parts Center : Our parts center operates around the clock, ensuring that you have access to essential components whenever you need them.

- Free Factory Layout Design : We offer complimentary factory layout design services to help you optimize your production space.

- Free Customized Shape Sample : We provide free samples of customized shapes, allowing you to see and test our designs before full-scale production.

- 3D Display of Equipment Scheme : Our 3D display services give you a clear and detailed view of your equipment setup, aiding in planning and decision-making.

- Customer Factory Production Tours : We offer tours of customer factories to showcase real-world applications of our machines and demonstrate their reliability and performance.

Get a Quote Now!

- Experience the difference with our reliable, high-quality machines and professional support. Contact us today to get a quote and start your journey towards enhanced production efficiency and quality.