Last Updated on 7 June, 2024 by jymachinetech

Jelly candies, with their colorful appeal and delightful chewiness, are a favorite among confectionery lovers. However, producing these treats requires adherence to stringent food safety standards to protect consumers and maintain product quality.

This comprehensive article explores the critical measures that can be taken to ensure that a jelly candy making machine maintains the highest levels of food safety.

1. Selection of Raw Materials

Ensuring food safety begins with the selection of raw materials. High-quality ingredients that meet safety and hygiene standards are essential. Suppliers should be vetted, and ingredients should be traceable and documented.

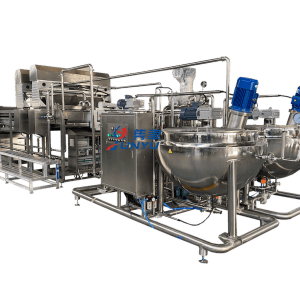

2. Machine Design and Construction

The design and construction of the jelly candy making machine play a crucial role in food safety. Machines should be made from food-grade materials, such as stainless steel, which is non-toxic, easy to clean, and resistant to corrosion.

3. Cleanability

The machine must be easily cleanable to prevent the buildup of residue, which can lead to contamination. Smooth surfaces, absence of crevices, and proper sealing are key features that facilitate thorough cleaning and sanitation.

4. Regular Maintenance

Scheduling regular maintenance checks is vital for food safety. This includes inspecting and replacing worn parts, checking for leaks, and ensuring all components are functioning correctly to avoid any risk of contamination.

5. Personnel Training

Proper training of operators is essential. Staff should be trained in food safety protocols, machine operation, and hygiene practices to minimize the risk of human error leading to contamination.

6. Hygienic Operation Conditions

Maintaining a hygienic environment around the machine is critical. This includes proper ventilation, temperature control, and cleanliness of the workspace to prevent any external contaminants from affecting the candy production.

7. Use of Protective Barriers

Protective barriers such as screens or curtains can be used to shield the jelly candy making machine from potential contaminants in the air or from accidental contact.

8. Compliance with Regulations

Adherence to local, national, and international food safety regulations is mandatory. This includes understanding and following guidelines set by the FDA, EU Food Safety Authority, and other relevant bodies.

9. Implementation of HACCP

The Hazard Analysis Critical Control Point (HACCP) system should be implemented to identify potential hazards and establish preventive measures at each stage of the production process.

10. Allergen Management

Proper allergen management is crucial, especially for facilities that produce multiple products. This includes using separate equipment, cleaning procedures, and clear labeling to prevent cross-contamination.

11. Pest Control

Effective pest control measures must be in place around the production area to prevent any infestations that could lead to contamination of the jelly candies.

12. Waste Management

Proper waste management practices should be followed to ensure that discarded materials are removed promptly and hygienically from the production area.

13. Monitoring and Testing

Regular monitoring and testing of the final product for microbial contamination, chemical residues, and other safety parameters ensure that the jelly candies are safe for consumption.

14. Traceability and Recall Systems

Establishing a robust traceability system allows for the tracking of products throughout the supply chain. This is essential for initiating recalls if any safety issues are detected after the product has left the facility.

15. Use of Appropriate Sanitizers

The use of appropriate sanitizers and disinfectants is necessary for cleaning the machine and the surrounding environment. These should be approved for use in food production and used according to manufacturer guidelines.

16. Temperature and Humidity Control

Controlling the temperature and humidity in the production area is important to prevent the growth of microorganisms that could contaminate the jelly candies.

17. Employee Health and Hygiene

Employees should adhere to strict personal hygiene practices, including regular handwashing, wearing clean uniforms, and following any health and safety protocols, especially if they have been in contact with illness.

18. Documentation and Record Keeping

Maintaining detailed records of production runs, cleaning schedules, maintenance checks, and any incidents or deviations is essential for quality assurance and regulatory compliance.

19. Continuous Improvement

A commitment to continuous improvement ensures that food safety practices are regularly reviewed and updated in line with new research, technology, and industry best practices.

20. Third-Party Audits

Regular third-party audits by independent organizations can provide an objective assessment of the machine’s compliance with food safety standards and identify areas for improvement.

Conclusion

Ensuring that a jelly candy making machine maintains food safety standards is a multifaceted endeavor that requires vigilance at every step of the production process. From the selection of raw materials and the design of the machine to the implementation of strict hygiene and safety protocols, each aspect plays a critical role in protecting consumers and upholding the reputation of the confectionery manufacturer. By adopting a proactive and comprehensive approach to food safety, producers can create an environment where the creation of delicious and safe jelly candies is the standard.

Why Choose Us?

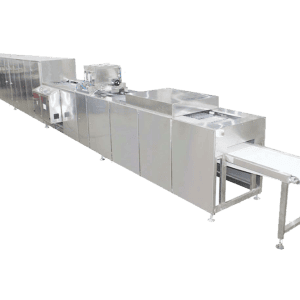

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.