| 型号Modelo | 400 | 800 | 1000 | 1200 | 1600 |

| 产能Capacidade (φ90mmpcs/h) | 2000 | 4000 | 5000 | 6000 | 8000 |

| 气炉Forno a gás (m³/h) | 10 | 12 | 15 | 20 | 24 |

| 用电量Consumo de energia (Kw/h) | 18 | 20 | 25 | 30 | 35.5 |

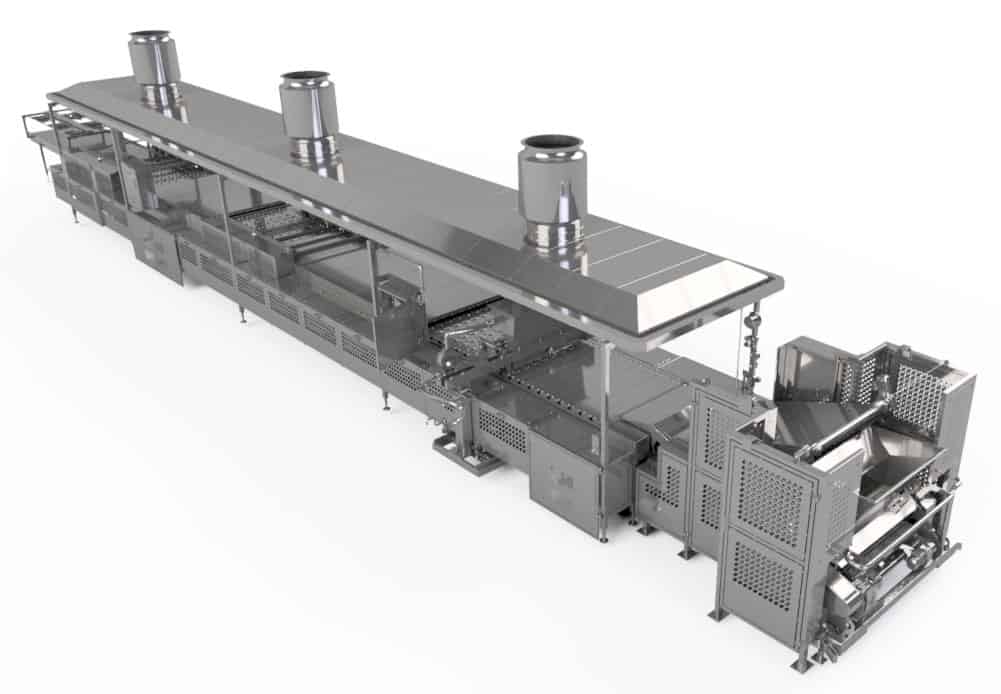

1,Capacidade: 2000pcs-8000pcs/h;

2,Modelo da máquina: JY400 - JY1600

3, Nome da máquina: Linha de produção automática de bolo dorayaki

4, Etapa de processamento: mistura, formação, cozimento, movimentação, queda, resfriamento, giro rápido e lento, enchimento, empilhamento, combinação, transporte por UV, embalagem

5,Principal matéria-prima: açúcar, farinha, glicose, água, ovo, chocolate, leite em pó, sabor, cor

6,Espaço necessário para a oficina: mais de 200 metros quadrados

7, espaço da oficina de produtos finais: mais de 100 metros quadrados

8. Espaço da oficina de matéria-prima: mais de 100 metros quadrados

9. trabalhador para cada turno: 10 a 15 pessoas

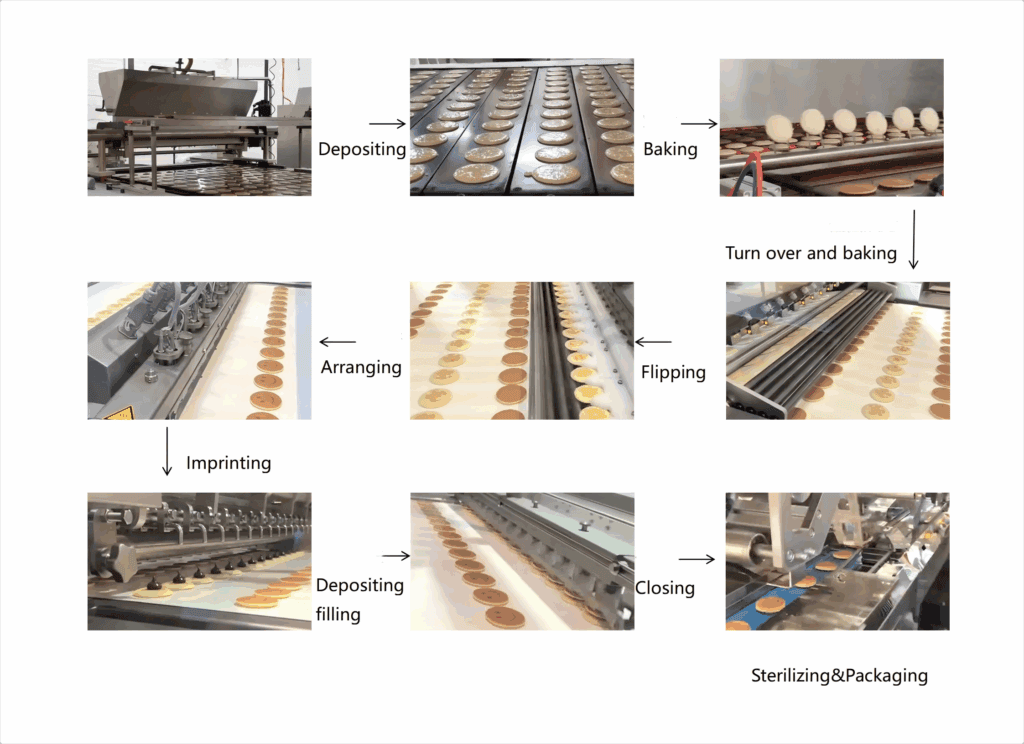

COMO FAZER DORAYAKI CAKES

Os sistemas de bolo Dorayaki são compostos por duas máquinas conectadas. A chapa para bolo e a sanduicheira funcionam de forma independente, mas são totalmente sincronizadas.

Para assar, usamos uma placa de cobre reforçada. A extraordinária capacidade de retenção de calor produz uma superfície de panqueca muito lisa. Tanto o gás quanto a eletricidade podem ser usados como fonte de calor para assar os produtos. Ao alterar a velocidade da chapa e a posição do depositador, o tempo de cozimento pode ser ajustado. Um aquecedor montado na parte superior do sistema de produção de panquecas cozinha a panqueca a partir da parte superior antes de virá-la. As posições do aquecedor montado na parte superior e do virador também podem ser ajustadas para atender a diferentes receitas. Abaixo da máquina de produção de dorayaki, os resíduos são removidos das placas da chapa e o óleo é aplicado para garantir que as panquecas sejam liberadas adequadamente.

A máquina de sanduíches primeiro alinha os produtos que chegam da máquina de panquecas e, em seguida, vira metade das fileiras de panquecas para aplicar o recheio. A outra fileira de panquecas não é virada, elas permanecem viradas para cima para permitir a impressão. Finalmente, a panqueca está pronta para ser colocada em um sanduíche e será selada para manter o recheio. A unidade de selagem pode fechar a panqueca, mantendo o recheio dentro, ou apenas colocá-la em um sanduíche, deixando as bordas abertas.