Last Updated on 24 May, 2024 by jymachinetech

Popping boba pearls, also known as tapioca pearls or bubble tea pearls, have become a global sensation, adding a delightful chewy texture to a variety of beverages.

These little black pearls might be small, but they pack a big punch in the world of bubble tea. But how are these tasty morsels created? Let’s take a behind-the-scenes look at the factory production line and the machinery involved in making popping boba pearls.

1. Raw Material Preparation:

The process begins with the selection of high-quality tapioca starch or a blend of starches, which is the primary ingredient giving boba pearls their distinctive chewiness. The starch is sourced from cassava root, a starchy tuber.

2. Mixing and Cooking:

In the factory, the starch is mixed with water to form a dough-like consistency. This mixture is then cooked under high heat to gelatinize the starch, which is essential for the pearls’ texture. The cooking process is carefully controlled to ensure the pearls achieve the right firmness and elasticity.

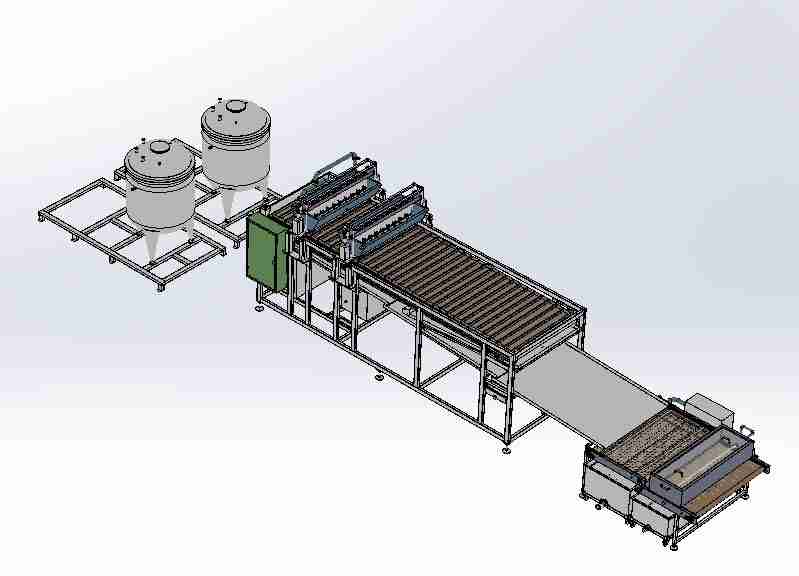

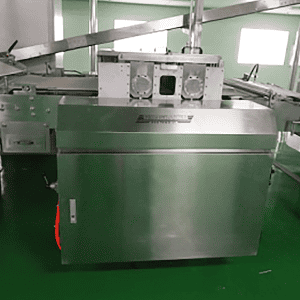

3. Mechanical Shaping:

Post-cooking, the gelatinized starch is passed through an extrusion machine, which shapes the dough into small, round pearls. This machine has multiple small nozzles that precisely form each pearl and is a crucial part of the automated production line.

4. Steaming:

The shaped pearls are then steamed to further cook and solidify their structure. This step is vital for achieving the final texture and for making the pearls ‘poppable’.

5. Cooling and Drying:

After steaming, the pearls are cooled rapidly to stop the cooking process and to prepare them for drying. The cooling process is typically done using a series of cooling belts or fluidized bed dryers.

6. Drying:

The boba pearls are then dried to remove excess moisture. This is often done using hot air circulation in a controlled environment to ensure the pearls dry evenly and maintain their shape.

7. Flavoring and Sweetening:

Once dried, the pearls are often flavored and sweetened. This can be done by tumbling the pearls in a mixer with flavorings and sweeteners, ensuring an even distribution throughout the batch.

8. Quality Control:

Throughout the process, quality control checks are performed to ensure the pearls meet size, shape, texture, and taste specifications. This includes visual inspections, texture assessments, and microbiological testing to ensure food safety.

9. Packaging:

The flavored and dried pearls are then packaged into appropriate-sized bags or containers. The packaging process is automated and includes sealing and labeling the products with nutritional information and usage instructions.

10. Storage and Distribution:

Finally, the packaged pearls are stored in a cool, dry place before being distributed to retailers and wholesalers. Proper storage is essential to maintain the quality and texture of the pearls until they reach the consumer.

Conclusion:

The creation of popping boba pearls is a fascinating process that combines traditional techniques with modern machinery and technology. From the careful selection of raw materials to the intricate steps of mixing, cooking, shaping, and drying, each stage plays a critical role in producing the chewy and delicious pearls enjoyed in bubble tea around the world.

Author’s Note: This article provides an overview of a typical production process for popping boba pearls. Actual methods may vary by manufacturer, and it’s essential to choose products from reputable companies that adhere to good manufacturing practices (GMP) and comply with relevant health and safety regulations.

Why Choose Us?

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.