Jun Yu provides an automatic biscuit production line tailored for your needs. You can browse related products and initiate consultations on our website.

@jymachinetech – Whether it’s raw material processing to packaging, or consumption to energy, or from simple to fully automatic equipment, our biscuit production line solutions come with turnkey project support, humanized design, and a reasonable quotation scheme including added-value options.

Our biscuit production line offers reliable performance and smart automation for large-scale baking needs.

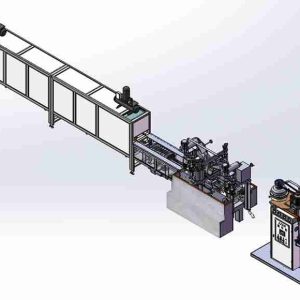

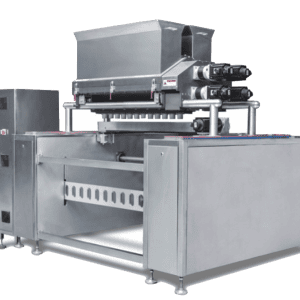

Biscuit production on a large scale relies on advanced production lines designed specifically for the food processing industry. A modern biscuit production line consists of several integrated stages, including dough mixing, dough forming, baking, and packaging. These stages are supported by state-of-the-art machinery and equipment, all working together to maximize production efficiency and ensure consistent product quality. Leading manufacturers in the industry offer a variety of biscuit production lines tailored to meet specific production requirements, allowing companies to produce high volumes of biscuits while maintaining strict quality standards. By utilizing these complete lines, manufacturers can efficiently produce a wide range of biscuit products to satisfy market demand.

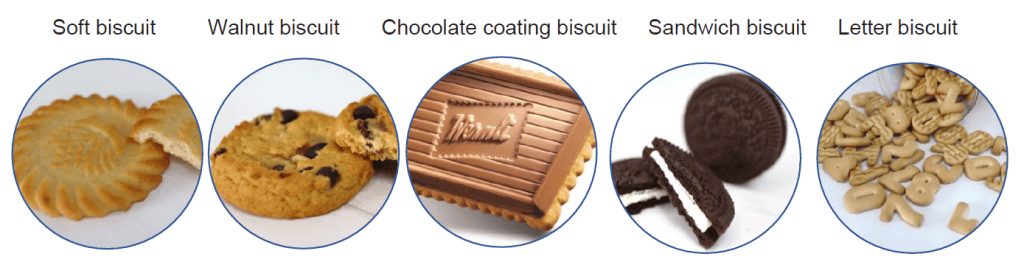

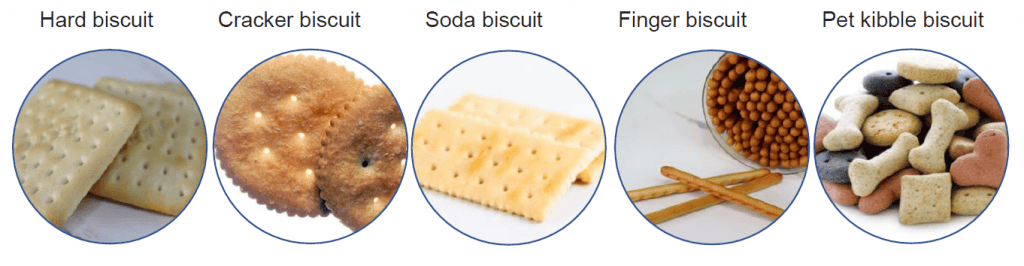

This production line is engineered to produce a diverse selection of biscuit types, including soft dough biscuits, hard biscuits, sandwich biscuits, and crackers. Whether your production needs focus on traditional hard biscuits or innovative soft dough recipes, the line can be customized to handle various formulations and shapes. With flexible equipment and adjustable settings, manufacturers can easily switch between different biscuit types, increasing production capacity and expanding their product range. This versatility makes the biscuit production line an ideal solution for companies aiming to produce multiple biscuit varieties and meet evolving consumer preferences.

We will design the best layout according to your factory space and equip the most suitable machines to make your ideal biscuits.

Maintaining peak performance in biscuit production requires regular maintenance and timely repair of all key components, including tunnel ovens and dough mixers. Establishing a routine maintenance schedule helps prevent unexpected equipment breakdowns, reduces downtime, and extends the lifespan of the machinery. Regular inspections and servicing of critical equipment ensure that the production line continues to operate efficiently, producing high-quality biscuits with minimal waste. Manufacturers should also have a clear plan for repairing or replacing equipment as needed, which helps control labor costs and maintain consistent production output. Prioritizing maintenance and repair is essential for sustaining efficient, reliable biscuit manufacturing operations.