Our cookie production line offers versatile capacity options, ranging from 200kg to 2.5 tons per hour. This flexibility allows you to scale your production according to your needs. By simply changing the rotary molds, you can produce a variety of cookies, including shortbread, soft biscuits, chocolate cookies, and more. To ensure the highest quality and efficiency in your production, we provide thorough guidance on the dough and ingredients suitable for your specific products.

Before starting production, it’s crucial to determine the appropriate dough type and ingredients for your cookies. Here are some factors to consider:

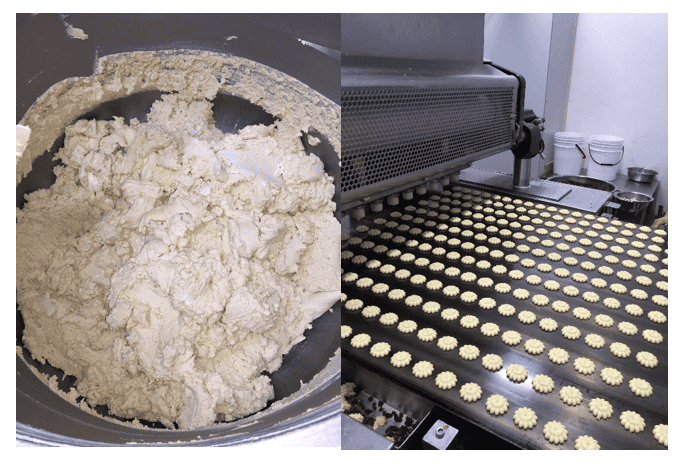

This dough mixer for soft biscuit mixing system with intelligent PLC control system & touch screen system with removal signal transmission.

Connecting with an automatic dough cutter & conveyor system can be fully automated processing.

Once both cookie and dough types have confirmed, we can begin to focus on cookie size and shape.

How many different cookie types would you like to produce?

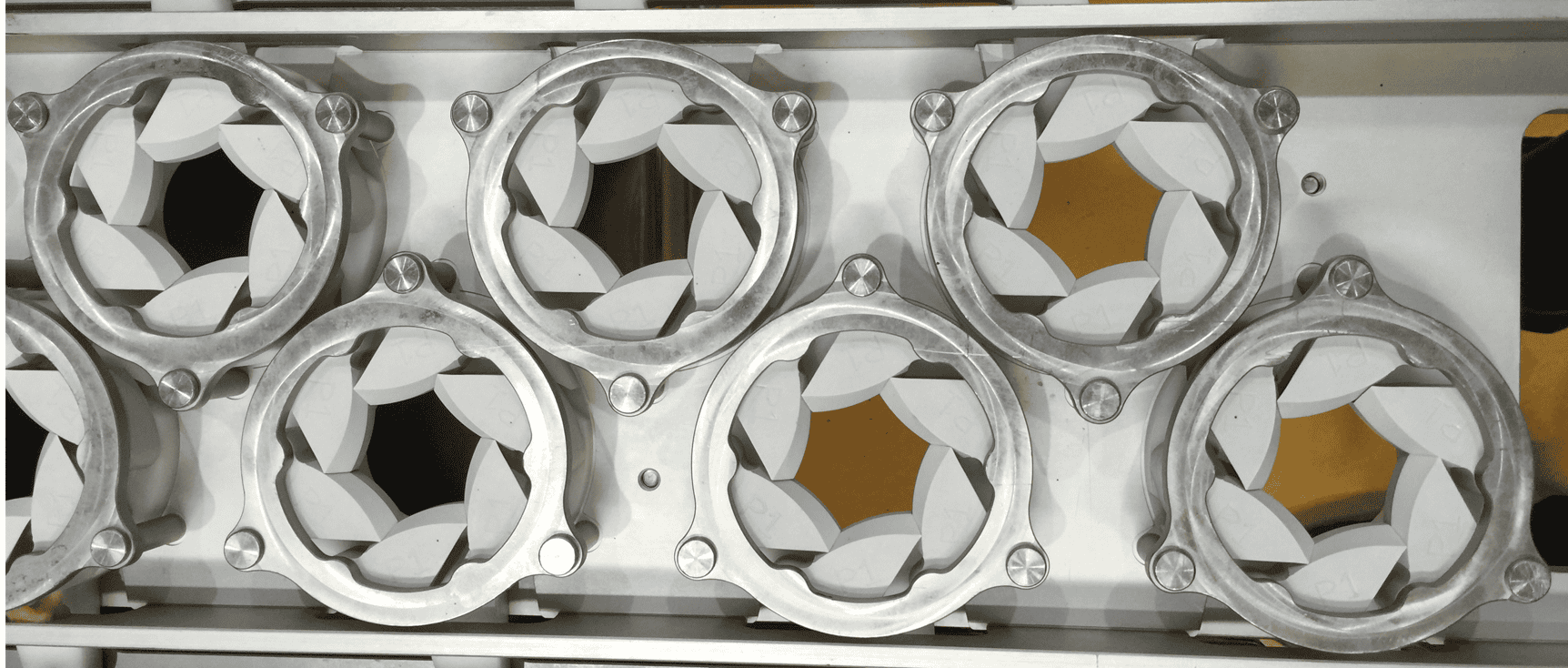

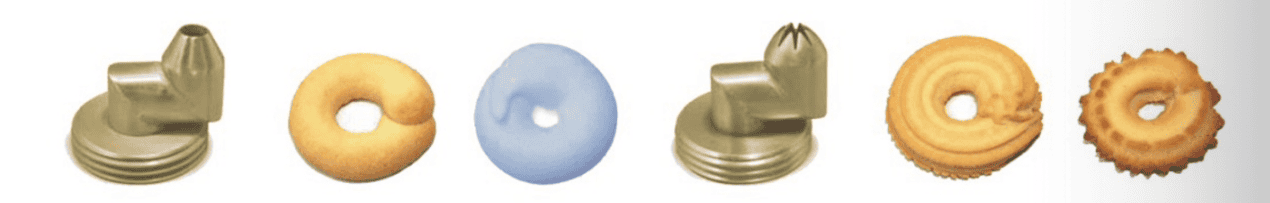

The rotary drop cookie processing machines usually can produce rotary and Multilevel drop cookies, which is the most common function for cookie machines.

One simple mounting pattern nozzles can produce hundreds of shapes by our cookie machines programs.

Customer can set the rotary speed & direction &time for the movement of the same nozzles to get different products.

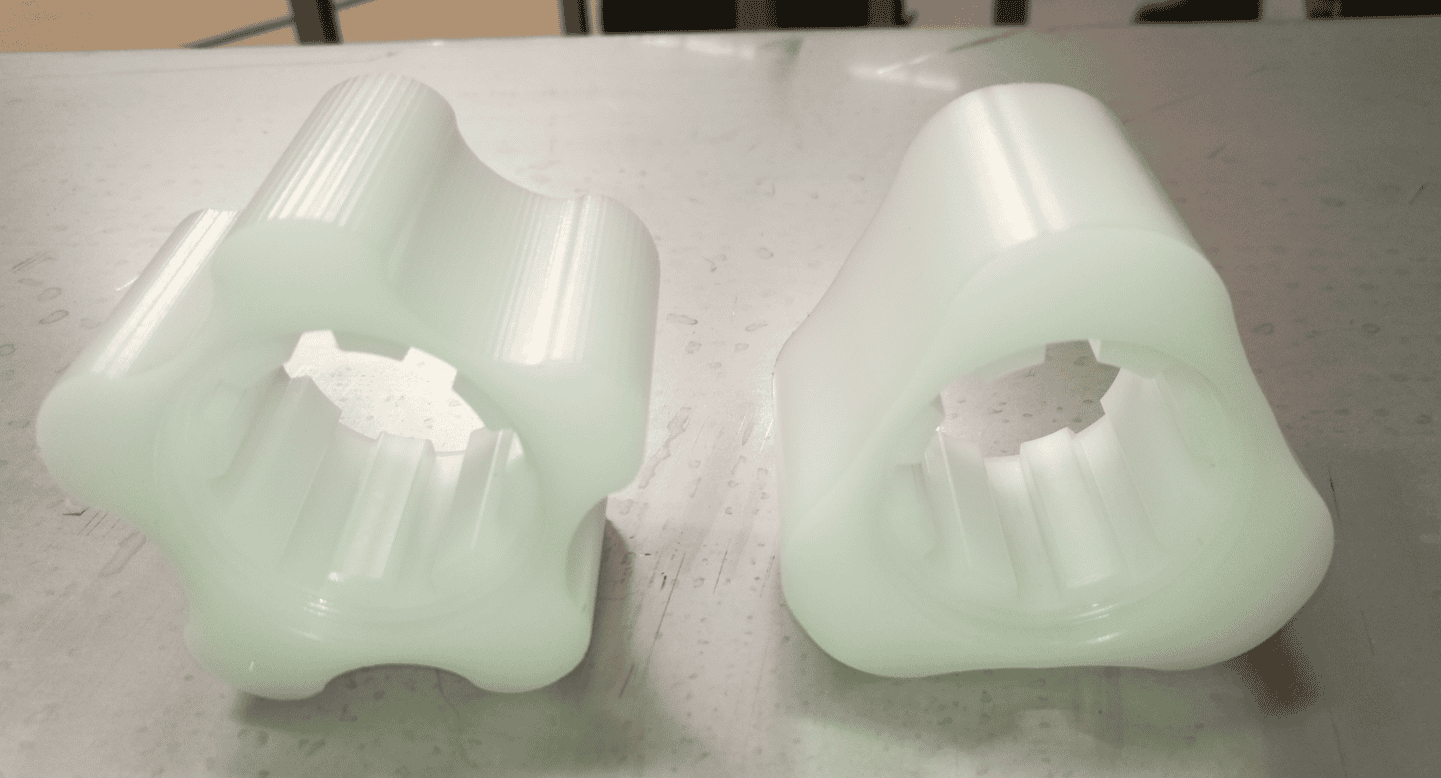

The deposit cookie dough through a round or shaped depositing head; just like you would do with a pastry bag.

The extruded cookie machines usually can produce multiple level Specialty Cookies inside with a close up inside the extruder nozzles

Whichever sweet treats you desire in your display case, it’s important to identify them early so that you can select your equipment accordingly.

This type of cookie production machine, designed for exceptional piece-weight accuracy and reliability, is perfect for making gingerbread, Christmas cookies, and a wide variety of other cookies that are rolled out and cut with cookie cutters, including round and square shapes. With our dual-color function, you can even create intricate checkerboard cookies.

The machine can be seamlessly integrated into the production line, positioned over the transfer belt or oven band, and easily removed without disrupting the conveyor system. The dual power drive for the soft biscuit rotary molder and conveyor can be adjusted separately, ensuring a seamless connection and superior biscuit molding effect.

We highly recommend that customers test our cookie processing machines or any other bakery equipment before committing to a purchase, as high-quality products rely on high-quality processing technologies. We all expect every packet of biscuits we open to contain perfectly baked cookies, and our machines are designed to meet this expectation consistently.

To ensure you find the perfect match for your biscuit production needs, our team offers complimentary equipment demonstrations and factory tours.

Baking is the key of delicate foods, our baking oven can customize into different temperature zones. Each oven zone is available with a variety of options to create a cost-effective system with a combination of radiation, convection heating and conduction.

Cookie oven can make different baking resources such as direct gas fired, convection and combination radiant/convection baking zones for improved baking efficiency.

Repeatable control of time, temperature, humidity and type of heat transfer

Maximum control over quality, color, taste and texture, pre-built in our factory for fast installation or assembled on-site.

Whether you want to increase the diversity of your existing product line or expand your existing biscuit production, choosing the right equipment is the key.

Correct biscuit production equipment can improve efficiency without sacrificing product quality.

cookies production line manufacturers

Maintaining a constant alignment and non-aggressive cooling are essential for obtaining a whole product that does not break, can be easily stacked and packaged.

More than 4,500 meters of cooling conveyors are carried out each year, transporting each cookie to stacking stations.

Subsequently, the biscuit can be conveyed to the packaging machines automatically or manually depending on the system and the speeds.

Our factory can provide the turnkey service for each customer. Once you’ve decided which cookie you’d like to start your production with, consider what capabilities you might like to have available in the future. Let’s find the suitable or customized solution for your cookie factory.