Last Updated on 14 June, 2024 by jymachinetech

Hello, confectionery commander! Are you gearing up to enter the delightful yet demanding domain of gummy manufacturing? If you’re about to dive into the world of chewy creations, it’s crucial to ensure that safety is not just on the menu, but the main course.

In this article, we’ll explore the safety features of a gummy manufacturing machine, because when it comes to making gummies, we want everyone to go home with a smile, not a frown.

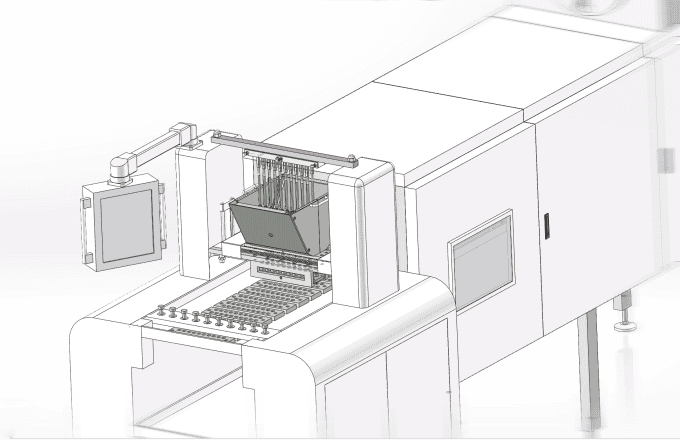

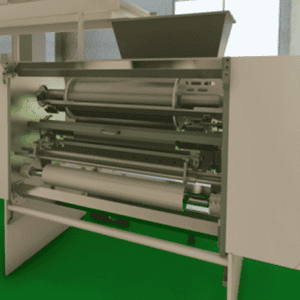

1. Enclosed Guarding: The Invisible Shield

Let’s start with the first line of defense: enclosed guarding. Picture a knight in shining armor, protecting the inner workings of your machine from any accidental contact. These guards prevent operators from coming into contact with moving parts, ensuring that only the ingredients get mixed, not any fingers.

2. Emergency Stop Buttons: The Panic Button

We’ve all had those moments when we hit the ‘panic button’ in our cars, and the same principle applies to gummy manufacturing machines. Emergency stop buttons are strategically placed so that at the first sign of trouble, the machine can be halted immediately, stopping any potential hazards in their tracks.

3. Interlocking Systems: The Gatekeeper

Interlocking systems act as gatekeepers, ensuring that certain parts of the machine can only function when other parts are safely in place. For example, a machine might not start if a safety door is open, preventing the machine from operating with any access points open.

4. Safety Sensors: The Watchful Eyes

Imagine having a set of watchful eyes that can detect when something goes awry. Safety sensors in gummy manufacturing machines do just that. They monitor the operation and can automatically stop the machine if an unsafe condition is detected, like a foreign object in the mixing area or an operator’s hand too close to a moving part.

5. Temperature Control Safety: The Heat Watcher

Since gummy production involves heating elements, temperature control safety features are vital. These features ensure that the machine doesn’t overheat, which could lead to burns or fire hazards. They’re like a thermostat with superpowers, keeping the temperature in check.

6. Pressure Relief Valves: The Pressure Cooker’s Friend

In cases where the machine uses pressurized systems, pressure relief valves are installed to release excess pressure. These valves are like a safety valve on a pressure cooker, ensuring that the machine doesn’t explode from too much ‘steam’—figuratively speaking, of course.

7. Proper Labeling and Signs: The Silent Guides

Clear labeling and safety signs are the silent guides that help operators navigate the machine safely. They provide crucial information about hazards, operating procedures, and safety instructions, ensuring that everyone knows where to go and what to do.

8. Training and Manuals: The Knowledge Base

Manufacturers provide comprehensive operator training and safety manuals that are like treasure maps, guiding you through the safe operation of the machinery. Understanding and following these guidelines is essential for preventing accidents and ensuring a safe work environment.

9. Regular Maintenance and Inspections: The Health Check

Just as we go for regular health check-ups, a gummy manufacturing machine also requires routine maintenance and inspections. This helps to identify and rectify potential hazards before they become serious issues, ensuring the machine stays in tip-top shape.

10. Lockout/Tagout Procedures: The Safety Lock

Gummy manufacturing machines should have established lockout/tagout procedures, which ensure that machinery is safely stopped and isolated for maintenance or repair work. This is like putting a ‘Do Not Disturb’ sign on a hotel room door, but for the machine.

11. Noise Reduction Features: The Sound Muffler

To protect operators’ hearing, some gummy manufacturing machines include noise reduction features, such as soundproofing or noise-dampening enclosures. These features are like earplugs for the machine, ensuring that the work environment stays as quiet as a library—well, maybe not that quiet, but you get the idea.

12. Dust and Particle Control: The Cleanup Crew

Since the production process can generate dust or small particles, the machines may be equipped with ventilation systems or filters to control air quality. This cleanup crew helps to keep the air clean and the workplace healthy for everyone.

Conclusion

Safety is the cornerstone of gummy manufacturing, and the features of a gummy manufacturing machine are designed to protect both the product and the people who make it. From enclosed guarding and emergency stop buttons to interlocking systems and regular maintenance, these features work together to create a safe and efficient production environment. So, the next time you’re in the gummy factory, remember that these machines are equipped with a suit of armor to keep everyone safe and sound. And who knows, maybe one day, we’ll have a gummy knight to guard our gummies!

Remember: When operating a gummy manufacturing machine, safety should always be your top priority. By understanding and utilizing the safety features, you’re not just making gummies; you’re making memories that everyone can chew on happily and safely. Happy and safe gummy making!

Why Choose Us?

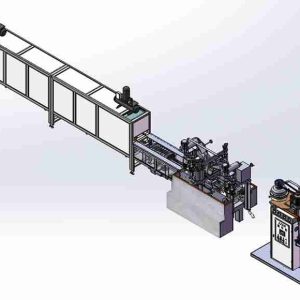

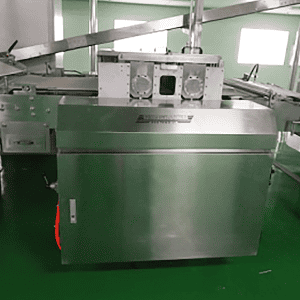

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.