Last Updated on 15 June, 2024 by jymachinetech

Greetings, gummy aficionados and candy connoisseurs! Are you ready to embark on a chewy journey through the fascinating world of gummy manufacturing?

Today, we’re going to explore the versatile and innovative ways gummy manufacturing machines handle different shapes and sizes of gummies.

So, let’s dive into the delightful process that transforms a simple mixture into a kaleidoscope of gummy delights.

1. The Art of Mold Design: Crafting the Blueprint for Gummies

At the heart of every gummy is its mold. Gummy manufacturing machines rely on precision mold designs to create the diverse shapes we know and love. These molds can range from the classic gummy bear to intricate, custom shapes that cater to specific themes or seasons.

The design process involves creating a 3D model of the desired shape, which is then used to produce the mold itself, typically from stainless steel or silicone.

2. The Science of Mold Making: Precision Meets Creativity

The mold-making process is a blend of science and creativity. It requires an understanding of the material properties and the manufacturing capabilities of the machine. For example, a mold for a gummy worm will have different requirements than one for a gummy star. The mold must be designed to allow for easy release of the gummy once it has set, without compromising the shape’s integrity.

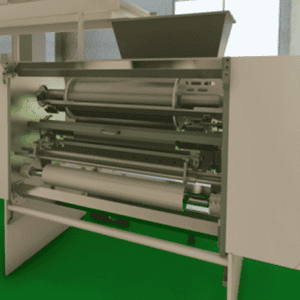

3. The Role of Molding Machines: Sculpting the Gummy Mass

Once the molds are ready, it’s time for the gummy manufacturing machine to take center stage. These machines are equipped with multiple mold cavities, each designed to produce a specific shape. The gummy mixture, which consists of ingredients like sugar, gelatin, and flavorings, is carefully heated and prepared before being poured or injected into the mold cavities.

4. The Precision of Depositing: Ensuring Uniformity in Every Gummy

Ensuring that each gummy has the same shape and size is crucial for maintaining product quality and consistency. Gummy manufacturing machines use precise depositing systems to control the amount of gummy mixture that goes into each mold cavity. This can be done through automated pistons, pumps, or even extrusion systems that fill the molds with accuracy and repeatability.

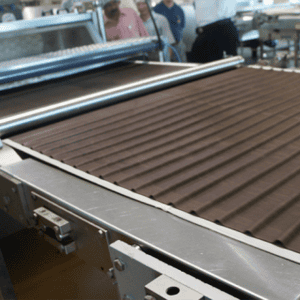

5. The Cooling Process: Setting the Gummy Shape

After the molds are filled, the gummy mixture needs to cool and set to maintain its shape. Gummy manufacturing machines have built-in cooling systems that regulate the temperature and duration of this process. The cooling process is carefully controlled to ensure that the gummies solidify uniformly and maintain their shape without deforming.

6. Demolding: The Gummy Liberation

Once the gummies have set, it’s time to release them from their molds. Demolding is a delicate process that requires precision to avoid damaging the gummies. Gummy manufacturing machines use various techniques for demolding, such as ejector pins that gently push the gummies out of the molds or a release mechanism that separates the mold halves to release the gummies.

7. Handling Complex Shapes: The Challenge of Intricate Designs

For more complex or intricate shapes, additional steps may be required. For example, gummies with multiple colors or patterns may need to be created in stages, with each color layer carefully applied before the next. This requires a machine with advanced capabilities and precise control over the filling process.

8. The Importance of Flexibility: Adapting to Different Gummy Sizes and Shapes

One of the key advantages of modern gummy manufacturing machines is their flexibility. These machines can be adapted to produce a wide range of gummy sizes and shapes, from small, bite-sized gummies to larger, more elaborate designs. This adaptability allows manufacturers to cater to diverse market demands and create gummies that stand out on the shelf.

9. Quality Control: Ensuring Perfection in Every Gummy

Throughout the manufacturing process, quality control plays a crucial role in ensuring that every gummy meets the desired standards. Gummy manufacturing machines often incorporate sensors and cameras that monitor the shape, size, and appearance of the gummies as they are produced. This helps to identify and rectify any issues that may arise during production.

10. The Future of Gummy Manufacturing: Innovation in Shape and Size

As technology advances, so does the capability of gummy manufacturing machines. Innovations such as 3D printing and advanced mold-making techniques are opening up new possibilities for creating gummies in virtually any shape or size. This ongoing evolution ensures that the world of gummy manufacturing remains exciting and full of potential.

Conclusion

The process of handling different shapes and sizes of gummies in manufacturing machines is a testament to the ingenuity and precision of modern confectionery equipment. From the initial mold design to the final product, each step is carefully controlled to ensure that every gummy is a perfect representation of its intended shape.

Whether you’re a gummy manufacturer looking to expand your product range or a consumer curious about the magic behind your favorite treats, understanding this process reveals the 嚼嚼嚼—yes, that’s “chew chew chew”—effort that goes into creating the gummies we all enjoy.

Remember: The next time you pop a gummy bear or any other shaped gummy into your mouth, take a moment to appreciate the sophisticated machinery and skilled craftsmanship that brought it to life. And who knows, you might even find yourself inspired to create your own unique gummy shapes! Happy gummy chewing!

Why Choose Us?

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.