Hello, future gummy mogul!

Are you ready to embark on a quest to create the most delectable, unique, and customized gummy treats the world has ever seen? If you’ve ever looked at a gummy bear and thought, “This could be better,” then you’re in the right place.

Let’s explore the exciting realm of customizing gummy manufacturing machines to meet your specific production needs.

1. Understanding Your Gummy Vision

Before we dive into the machinery, it’s crucial to have a clear vision of the gummy empire you want to build. Are you dreaming of gummy bears with a twist, or perhaps a whole new shape that’s yet to be discovered? Understanding your vision will guide the customization process and ensure your machine is tailored to your unique gummy dreams.

2. Selecting the Right Base Machine

The first step in customization is selecting the right base machine. Gummy manufacturing machines come in various sizes and capabilities, from small, artisanal machines to large, industrial-scale behemoths. Choose a machine that fits the scale of your operation and has the potential for customization to meet your specific needs.

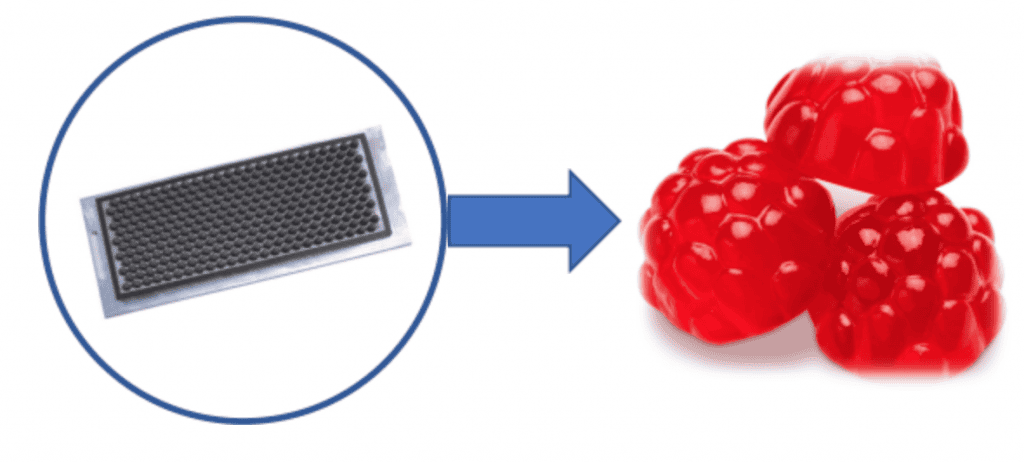

3. Mold Customization: Shape and Size

One of the most exciting aspects of customizing a gummy manufacturing machine is mold customization. Whether you want to create gummy bears, worms, or even 3D printed gummy sculptures, custom molds are the key. Work with manufacturers to design molds that can produce the exact shapes and sizes you have in mind.

4. Flavor and Color Dispensing Systems

Next up, let’s talk about the flavor and color dispensing systems. Customizing these systems allows you to control the intensity and distribution of flavors and colors in your gummies. Whether you want a uniform taste throughout or a surprise filling, a customizable dispensing system can make it happen.

5. Ingredient Proportions and Quality

The heart of any gummy is its ingredients, and a customizable gummy manufacturing machine allows you to control the proportions and quality of each component. From adjusting the sugar levels to incorporating high-quality natural flavors, you can ensure your gummies are made to your exact specifications.

6. Temperature and Cooking Time Control

Temperature and cooking time are critical factors in achieving the perfect gummy texture. Customizing the temperature and cooking time control systems in your machine ensures that every batch is cooked to perfection, resulting in gummies with the desired chewiness and consistency.

7. Automation and Production Speed

If you’re looking to scale up your gummy production, consider customizing the automation and production speed of your machine. From semi-automatic to fully automatic systems, you can tailor the machine’s operation to match your production goals and workforce capabilities.

8. Quality Control and Inspection Systems

Ensuring the quality of your gummies is paramount, and customizing the quality control and inspection systems in your machine can help you maintain high standards. From weight and size checks to visual inspections, a customized system can identify and eliminate any inconsistencies in your gummy production.

9. Hygiene and Cleaning Systems

In the world of confectionery, hygiene is not a joke—it’s a must. Customizing your machine’s hygiene and cleaning systems ensures that it meets the highest standards of cleanliness and safety. This includes easy-to-clean components, automated sanitation cycles, and compliance with food safety regulations.

10. Energy Efficiency and Sustainability

As we look to the future, energy efficiency and sustainability are becoming increasingly important. Customizing your gummy manufacturing machine to be more energy-efficient not only reduces your environmental impact but can also save on operational costs in the long run.

11. Software Integration and Control Systems

In our tech-savvy world, software integration is a game-changer. Customizing the control systems of your machine to include advanced software can provide real-time monitoring, data analytics, and remote control capabilities, making your production process smarter and more efficient.

12. Custom Coatings and Finishing Options

For those gummies that require an extra touch of elegance, custom coatings and finishing options can set your gummies apart. Whether it’s a chocolate coating, a sugar dusting, or a special glaze, customizing the finishing process can add that unique flair to your gummies.

13. Research and Development Support

Customizing a gummy manufacturing machine often involves a period of research and development to perfect your gummy recipe and production process. Working closely with machine manufacturers and leveraging their expertise can help you navigate this process and achieve the best results.

14. After-Sales Service and Customization Updates

Finally, when customizing your machine, consider the after-sales service and the potential for future customization updates. As your business grows and your gummy dreams evolve, you may need to make further adjustments to your machine. Ensuring that the manufacturer can provide ongoing support and updates will be invaluable.

Conclusion

Customizing a gummy manufacturing machine is like crafting a masterpiece with a team of experts at your disposal. By understanding your vision, selecting the right base machine, and tailoring every aspect from mold design to software integration, you can create a machine that not only meets but exceeds your production needs. So, roll up your sleeves, and let’s get to work on making your gummy dreams a reality. Remember, in the world of gummy customization, the only limit is your imagination—well, that and the laws of physics, but who’s counting?

Remember: When it comes to customizing your gummy manufacturing machine, think big, think bold, and most importantly, think chewy. The gummy universe is vast, and with a customized machine, you’re the architect of your own gummy galaxy. Happy customizing!