Last Updated on 29 March, 2024 by JY machinetech

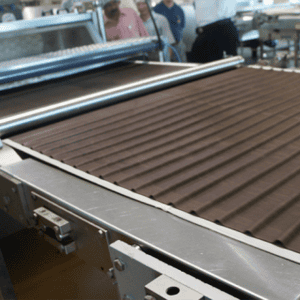

This plant is a new development in the food industry and is being used in a variety of food products. It is made of hygienic stainless steel (SUS316) and is produced using various forming plates. The process of manufacturing it can be automated, as well. This plant uses a variety of forming plates and can produce balls in a variety of sizes and shapes.

Yam cake

Agar is a food additive. Konjac is a plant that grows throughout East and Southeast Asia. It is also known as elephant yam, konnyaku, and snake palm. It is highly prized for its starchy corms. It is a vegan alternative to gelatin and is commonly used in cooking and drinks. How is it manufactured? Below is a step-by-step description of the manufacturing process.

SINOFUDE developed a special machine to manufacture Konjak agar balls. This is the only factory in China that has such a machine. It is made of stainless steel and adopts a PLC and SERVO control system. The agar boba can be made into any flavor and color. It is available in different colors and tastes, and can be customized to match a brand’s identity.

Healthy food

The deep processing process of konjak agar ball is based on the principle of rationally and fully using the remaining pieces of raw material. It also utilizes some by-product and scrap materials, which reduces the process loss. The resulting food is rich in flavor and nutrition. The factory also employs multiple means to improve the efficiency of food production, including product development and flavor technology.

In order to create Konjak agar balls, the powder is subjected to several processes, including water swelling, moulding, and alkalescence. The main material used for making these balls is a water-soluble dietary fiber with a high concentration of alkaline water. The high alkalinity and the difficult composition process make it a difficult food to manufacture.

Jelly

The production process for konjac agar balls begins with the harvesting of the seeds from the Japanese konjac plant. The resulting jelly is thick and can hold up to 200 times its weight in water. Although it is sweet, it’s not a good option for children because it is a choking hazard. In Australia, it is banned for children under 12 years old because some have choked to death after eating konjac jelly. The jelly is sold in powder form that must be mixed with boiling water before serving.

The konjac plant is found in tropical and subtropical areas of eastern Asia. Its native range includes Japan and China. This nutrient-rich plant is often called elephant yam or devil’s tongue. The concoction is made with calcium hydroxide, a substance commonly used for pickling. Depending on the taste of the resulting jelly, the Konjak agar ball may be clear, fruit-set, or have a tangy flavor.

Confectionery

A new food product is being developed from the Konjac plant – the agar ball. This chewy jelly-like substance is flavored with a subtly sweet citrus syrup. A factory has designed a production line that produces the balls from the Konjac plant. The machine is equipped with hygienic stainless steel parts and a user-friendly interface. The machine can produce konjac balls of any color and taste.

Dessert

Convenient and hygienic, the Konjak agar ball can be used in many food products. It is made from stainless steel and is available in various shapes, sizes and colors. A factory can manufacture Konjac agar balls with various forming plates and automatic processing. They can also be used for various drinks and desserts. In addition to the convenience of the Konjac agar ball, it is a healthy, natural food product.

Another application for konjac is as a fruit jelly snack. These snacks, often called lychee cups in the United States, are typically served in bite-sized plastic cups. The company that manufactures these snacks, MannanLife, is responsible for the high number of choking deaths. Consequently, the company warns consumers to cut the product into smaller pieces before serving it to small children.

Why Choose Us?

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.