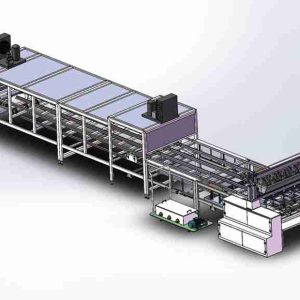

Our marshmallow processing line is complete & continuously produces various kinds of cotton candies(marshmallows) which come in a variety of colors and shapes.This highly aerated confectionery product by our creator machine it is delicately smooth and luxuriously fluffy.Our extruder machine can produce 4colors at single nozzles, and with muntiful shapes or twisted marshmallow rope.Our depositor machine can produce center-filled marshmallow like jam, chocolate fillings, or two colors like ice cream top.We have an automatic drying system with reguires o manual till packing.

Key Features & Benefits:

- High Aeration Quality: Our creator machine produces marshmallows that are delicately smooth and luxuriously fluffy, ensuring a premium quality product.

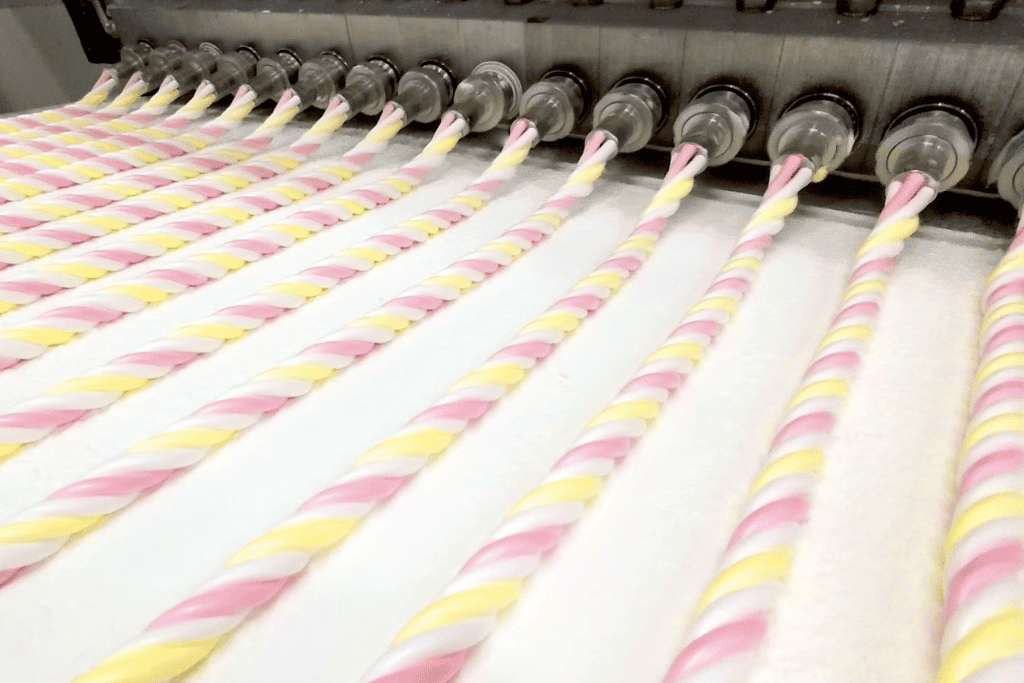

- Versatile Extrusion Capabilities: The extruder machine is capable of producing up to 4 colors at single nozzles, allowing for a multitude of shapes and twisted marshmallow ropes.

- Innovative Deposition Technology: Our depositor machine specializes in creating center-filled marshmallows with various fillings such as jam or chocolate, and even dual-colored marshmallows reminiscent of ice cream toppings.

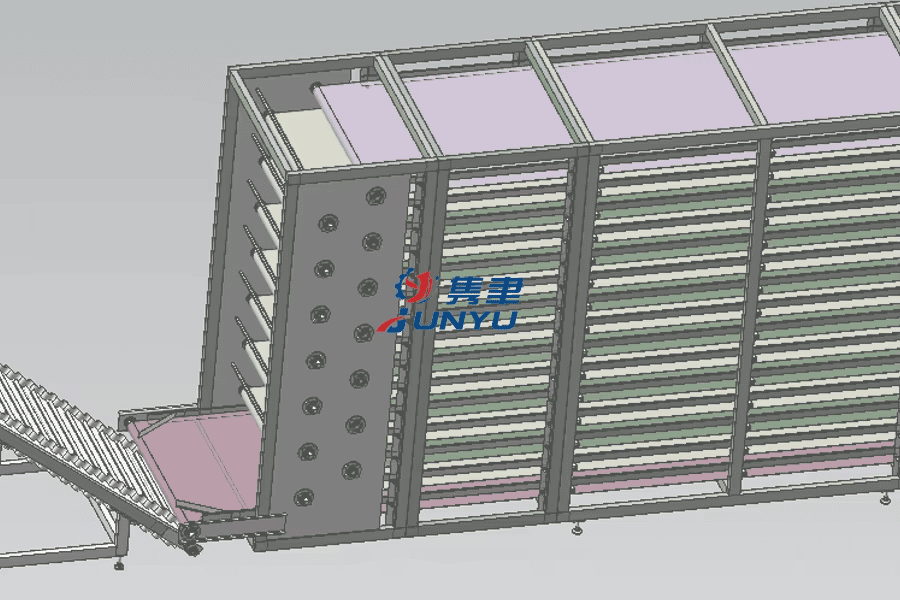

- Automatic Drying System: An integrated drying system that requires no manual intervention until the packing stage, streamlining the production process and reducing labor costs.

- Customizable Recipes: We offer a range of formulas, including Halal-type gelatin recipes, to cater to diverse market needs and preferences.

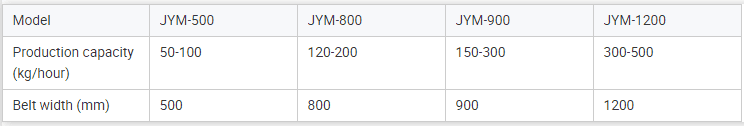

Model Specifications:

- Model JYM-500: Production capacity 50-100 kg/hour, belt width 500 mm.

- Model JYM-800: Production capacity 120-200 kg/hour, belt width 800 mm.

- Model JYM-900: Production capacity 150-300 kg/hour, belt width 900 mm.

- Model JYM-1200: Production capacity 300-500 kg/hour, belt width 1200 mm.

Components & Capabilities:

- Aerator: For optimal aeration and texture.

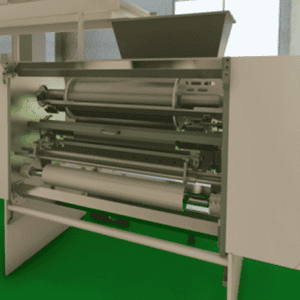

- Extruder: For shaping and color combination.

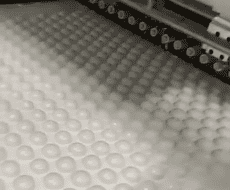

- Depositor: For precise filling and deposition.

- De-starch: To ensure a smooth and non-grainy texture.

- Drying System: For even and efficient drying of the marshmallows.

- Nozzles: Available in various designs for different marshmallow shapes.

Product Range:

- Mutiful Shapes: A variety of shapes to suit different tastes and occasions.

- Center Filled: Marshmallows with a surprise filling in the center.

- Rotary Striped: Marshmallows with a spiral pattern for an eye-catching appearance.

- Ice Cream Core Marshmallow: Dual-colored marshmallows perfect for ice cream toppings or standalone treats.

Why Choose Our Marshmallow Production Line?

- Overseas Service Team: Dedicated support from our international service team.

- North America Local Service: Local service for North American customers.

- Animal Machine Maintenance: Regular maintenance to keep your machines running smoothly.

- 24/7 Parts Center: Access to parts anytime, ensuring minimal downtime.

- Free Factory Layout Design: Customized factory layout design to optimize production flow.

- Free Customized Shape Sample: Samples of customized marshmallow shapes to meet specific demands.

- Product Formula Design: Assistance in formulating the perfect marshmallow recipe.

- Machine Design: Tailored machine design to fit your production needs.

- 3D Display of Equipment Scheme: A visual representation of the equipment setup for better planning.

- Customer Factory Production Tour: An opportunity to visit our factory and witness the production process firsthand.

How to make marshmallow

1) In the pre-mixer, all the ingredients to be dissolved and cooked.

2) Then the basic slurry is continuously pumped to a cooker till the final moisture level is reached.

3)After cooking, the slurry will be cooled.

4)Then the cooled "marshmallow base" is passed through the continuous aerator

5) The product then be divided and injection with different colors and favors.6) The multi-color product is extruded ,and transported on a cooling conveyor for cooling down.7) The conditioned marshmallows are dusted top and bottom with starch, or a mixture of both starch and icing sugar in a separate

dust cabin, the product is cut to the required length here.

8) The dust cabin is kept under a strict control to prevent the "dust" spreading throughout the plant. The excess starch/sugar is removed.9) Optional: The final is transferred to a chocolate enrobing machine for coating its surface with chocolate10)The coated products under cool down.

11)The final products are transferred to a packaging machine.

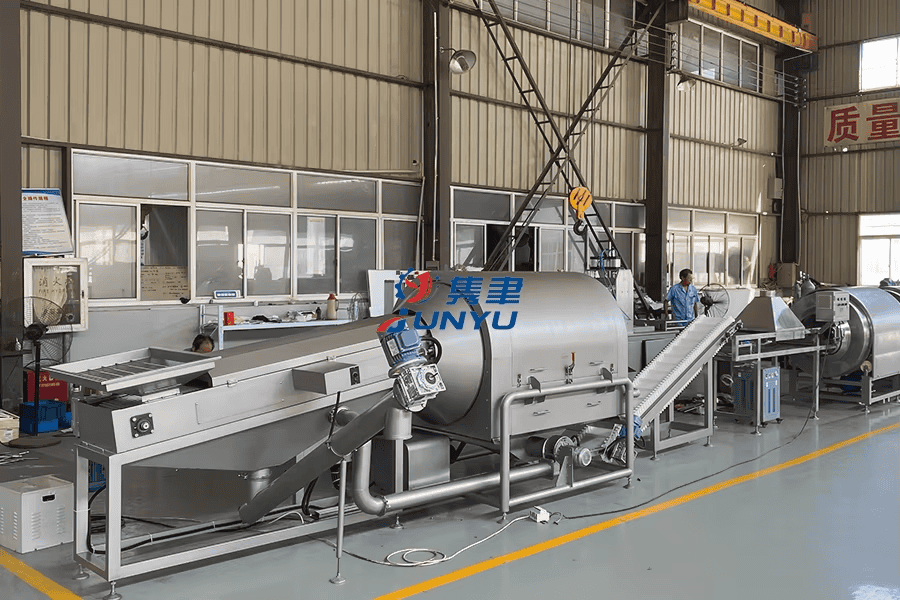

Professional & Reliable Real Factory:

Our commitment to quality and reliability is reflected in our real factory operations, ensuring that you receive a professional and dependable service.

Get a Quote Now:

For personalized pricing and to learn more about our Marshmallow Production Line, contact us today.

Why Choose Us?

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.