If you’ve ever wondered how a Crystal jelly ball is made, then this article is for you! We’ll cover everything from how they’re made to what you need to know before ingesting one! Whether it’s the production process or the characteristics of a crystal jelly ball, you’ll be glad you read it! After all, no one wants to end up with a swollen, shard-like ball!

Manufacturing process of Crystal jelly ball

The manufacturing process of Crystal jelly ball starts with the formation of the crystal product. It is then cooled to a solid state. This process is done slowly so as not to develop tensions that may cause cracks during later processing phases. Annealing is the process that ensures an even cooling of the product. It is carried out by heating the product to a temperature of 580 degrees Celsius for a period of twenty minutes or more, depending on the thickness of the crystal.

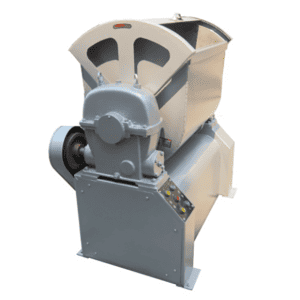

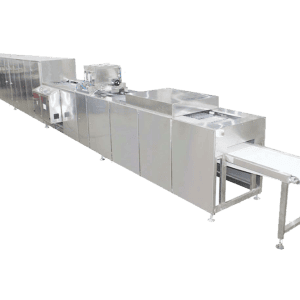

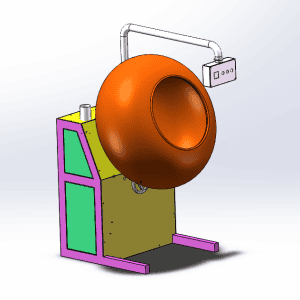

The next step of the manufacturing process involves the heating of the ingredients. Electric heating systems heat the jelly at a different rate than gas heating systems. When the mixture is hot, it is packed in the cooling tunnels to reduce its temperature. This process is followed by the addition of flavor and color. Once the ingredients are mixed and cooled, they are then poured into the molds. Manufacturing of these delicious balls can be a challenging process. But with proper safety measures, the manufacturing process of these balls can be a success.

Complications of ingesting a crystal jelly ball

Decorative crystal gel balls are popular as home decor items. These colored pellets made of superabsorbent polymer swell when they come into contact with liquids. Crystal balls can absorb up to 500 times their weight in water and can swell 30 to 60 times their original volume. If consumed, these balls can result in intestinal obstruction, perforation, or a serious infection.

One child who swallowed a SAP ball developed a perforated intestine. He had swallowed three of them. Surgical removal was required. Another baby, eight months old, developed a complete intestinal obstruction after swallowing three SAP balls. Both of these cases necessitated surgical removal of the balls. The US Consumer Product Safety Commission has since voluntarily recalled Water Balz and similar products. However, the company is continuing to sell SAPs, which are often used to hold flowers in vases.

Characteristics of a crystal jelly ball

A decorative crystal jelly ball is a popular way to adorn your home. A crystal jelly ball is a superabsorbent polymer that swells when in contact with water. It is common for jellyfish to mistake plastic bags for jellies, but they can cause a variety of serious complications when ingested. This case report examines what can happen if you accidentally ingest one.

Storage of a crystal jelly ball

Crystal jelly balls are often used in the home as decorative items. These tiny colored pellets of crystals are made of super-absorbent polymers. When placed in water, they swell, sometimes to more than 500 times their original volume. As they swell, they can be dangerous, if ingested, and can lead to perforation peritonitis or intestinal obstruction.

Because the crystals are mainly water, it’s important to remember to wash your hands after handling them. This prevents dirt and oil from being absorbed into the polymer. If you don’t, your crystals may become cloudy or even dirty. In addition, oily buildup on your hands can reduce the hooking points of the polymer, which means less absorption. Washing your hands after handling crystals will help extend their life and keep them fresh.

Why Choose Us?

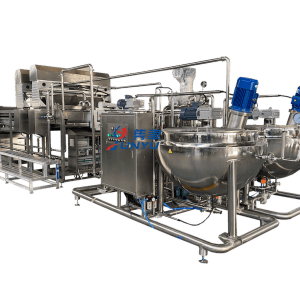

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.