Last Updated on 2 May, 2024 by JY machinetech

What are the ingredients that go into making a bar of chocolate? There are a few steps in this process, but we will talk about the basics. The ingredients in chocolate include cocoa butter, milk, sugar, and conching. In fact, chocolate is actually a mixture of several of these ingredients. The steps are described in detail below. In addition, you will get to know the different processes involved. This will help you make chocolate at home.

Conching

There are many processes that go into making chocolate, and it may be a surprise to learn how your favourite confectionery is made. The first step is cacao bean preparation, during which the cocoa powder and water are mixed. Then the mixture is heated to create a soft, creamy texture. Next, the chocolate is blended with sugar and milk, and then refined until it reaches the desired taste and texture. After this, the chocolate is ready to be moulded or filled, depending on the type of chocolate you’re interested in.

Cocoa butter

You may have wondered why cocoa butter is so important in chocolate making. It comes from the seeds of the cocoa bean and contains a variety of beneficial properties. It’s a stable fat, and its taste and smell are reminiscent of chocolate. It is commonly used in cooking, and is often used in chocolate making. Although it’s not stable enough to be kept in a refrigerator, it is useful in chocolate making because it helps temper the chocolate, preventing it from hardening too quickly.

Milk

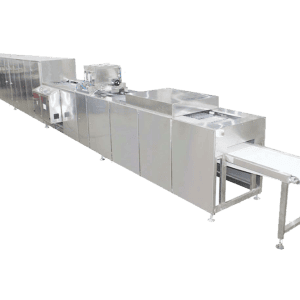

Milk chocolate is an item that is manufactured in factories. Many people may be a little skeptical of this process, but it actually doesn’t involve much effort on your part. It’s also one of the cheapest ways to get delicious treats for yourself and your family. Most factories produce their chocolate products in large batches. These factories use machinery to make their products. Whether you’re buying chocolate for a gift or to savor it, milk chocolate factories are highly efficient and hygienic.

Sugar

Consumers today demand a range of ingredients, from organic to fair-trade, and sugar is no exception. Sugar is one of the most popular sweeteners used in chocolate production, as well as a key ingredient in confectionery. Sugar has an important role in chocolate flavour, since it affects both the cocoa bean’s aroma and its overall flavour. Using a high-quality sugar will help chocolate makers meet both of these consumer demands.

Cocoa solids

During the process of chocolate manufacturing, cocoa solids are added to make chocolate bars and other confections. The amount of cocoa solids in a specific product is associated with the type of chocolate. For example, bittersweet chocolate contains 35 percent solids while dark chocolate can have as much as 40 percent. In comparison, milk chocolate contains less than 10 percent solids while white chocolate contains none. Unsweetened baking chocolate contains half solids and half cocoa butter. Consumers often think that higher solids percentages in a chocolate bar or confection are better.

Winnowing

Before the Industrial Revolution, cocoa beans were harvested by hand. The shell of the cocoa bean must be removed in order to extract its meat, called nib. This ancient agricultural process is essential in processing rice and wheat. Today, machines winnow cacao beans in factories, making this process faster and more efficient. But what happens during the process? This article will explore the process of winnowing cocoa beans and how it differs from hand-winnowing.

Quality

The production of quality chocolates in factories is closely controlled, starting from the raw cacao beans that are carefully washed and dried, to the final conching process that allows the cocoa to solidify and develop its flavor. Conching time is not a criterion of quality, as it depends on other ingredients, such as bean type, desired flavor profile, and application. In addition, machines also measure the amount of cocoa solids, which is the total percentage of cocoa by weight.

Why Choose Us?

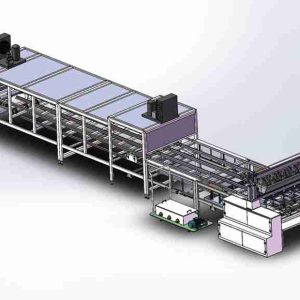

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.