Última actualización el 14 de junio de 2024 por jymachinetech

Hello, confectionery connoisseurs! Are you curious about the world behind those colorful, chewy gummies that fill our candy jars and sweeten our days?

Today, we’re going to take a closer look at the rigorous processes gummy manufacturing machines use to ensure that every gummy bear, worm, and slice we enjoy meets the highest food safety standards.

So, let’s dive into the chewy center of it all and see how these machines keep our treats safe and sound.

1. Rigorous Ingredient Sourcing

The journey to safe gummy production starts with the ingredients. Gummy manufacturing machines rely on high-quality, carefully sourced ingredients that meet stringent safety and hygiene standards.

From the gelatin and pectin to the fruit purees and flavorings, every component is checked and double-checked to ensure it’s safe for consumption.

2. Automated Systems: Less Human Touch, More Consistency

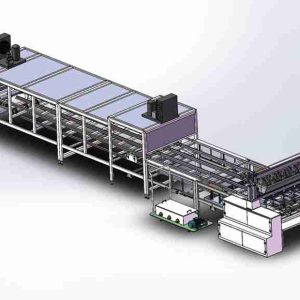

One of the key ways gummy manufacturing machines ensure food safety is through automation. By minimizing human contact with the product, these machines reduce the risk of contamination. From the moment the ingredients are mixed to the final packaging, automated systems maintain a high level of hygiene and consistency.

3. State-of-the-Art Equipment Design

The design of gummy manufacturing machines plays a crucial role in food safety. These machines are built with non-porous materials like stainless steel, which is easy to clean and resistant to corrosion. This design helps prevent the buildup of bacteria and ensures that gummies are produced in a clean environment.

4. Temperature Control: Cooking to Perfection

Proper temperature control is vital in gummy manufacturing. Machines are equipped with precise heating and cooling systems that ensure ingredients are cooked and set at the right temperatures. This not only affects the texture and taste of the gummies but also plays a critical role in killing any potential harmful bacteria.

5. Hygienic Processing Environments

Gummy manufacturing machines are often housed in controlled environments that meet high standards of cleanliness. These environments are regularly sanitized and maintained to prevent any contamination from the surrounding air or surfaces.

6. Advanced Cleaning and Sanitizing Protocols

After each production run, gummy manufacturing machines undergo thorough cleaning and sanitizing processes. These protocols involve the use of specialized cleaning agents and techniques to ensure that every part of the machine is free from residue and contaminants.

7. Regular Maintenance and Inspections

To keep the machines in top working condition, regular maintenance and inspections are conducted. This includes checking for wear and tear, replacing parts as needed, and ensuring that all safety features are functioning correctly.

8. Quality Control Checks at Every Stage

Quality control is an integral part of the gummy manufacturing process. At every stage, from mixing to packaging, the product undergoes rigorous testing to ensure it meets all food safety standards. This includes checks for taste, appearance, and most importantly, microbiological safety.

9. Compliance with Global Food Safety Regulations

Gummy manufacturing machines must comply with a host of global food safety regulations, such as those set by the FDA, EU Food Safety Authority, and other regulatory bodies. Compliance with these regulations is a testament to the machine’s commitment to safety.

10. Employee Training and Hygiene Practices

The people operating the machines are just as important as the machines themselves. Employees are trained in proper hygiene practices and are required to follow strict protocols when handling equipment and products to minimize the risk of contamination.

11. Use of Protective Barriers and Enclosures

During the production process, gummy manufacturing machines may be enclosed or protected by barriers to prevent any external contaminants from coming into contact with the gummies.

12. Allergen Management Protocols

For consumers with allergies, gummy manufacturing machines implement strict allergen management protocols. This includes the use of separate equipment, dedicated production lines, and clear labeling to prevent cross-contamination.

13. Traceability and Recall Systems

In the event of a safety concern, gummy manufacturing machines are equipped with traceability systems that allow for the tracking and recall of specific batches of gummies. This ensures that any potential issues can be quickly and effectively addressed.

14. Continuous Improvement and Adaptation

The world of food safety is always evolving, and gummy manufacturing machines must adapt to stay ahead. This includes incorporating new technologies, updating safety protocols, and staying informed about the latest research and best practices in food safety.

15. Third-Party Audits and Certifications

To further ensure food safety, gummy manufacturing machines and their processes are often subject to third-party audits and certifications. These audits provide an additional layer of assurance that the machines are meeting the highest safety standards.

Conclusión

The world of gummy manufacturing is a testament to the power of technology and the importance of food safety. From the moment the ingredients are sourced to the final packaging, gummy manufacturing machines are designed and operated with safety as their top priority. So, the next time you reach for a gummy bear, you can enjoy it with the confidence that it has been produced under the strictest safety standards. Here’s to the sweet scientists and their machines, making our candy jars a safer and more delicious place!

Recordar: Every chewy, colorful gummy is the result of a carefully controlled process that puts your safety first. As you savor each bite, take a moment to appreciate the dedication to quality and safety that goes into creating your favorite gummy treats. Happy chewing!

¿Por qué elegirnos?

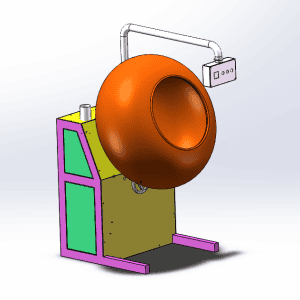

Shanghai Junyu comenzó como un fabricante de equipos alimentarios especializado en diversos tipos de maquinaria para la industria alimentaria. Nuestra gama incluye máquinas para hacer galletas, máquinas para hacer dulces, máquinas para hacer chocolate, máquinas para hacer obleas, máquinas para hacer pasteles, máquinas para empacar y más. Con un compromiso con la calidad y la innovación, nos esforzamos por proporcionar equipos de primer nivel para satisfacer las diversas necesidades de nuestros clientes en el sector de fabricación de alimentos.

Gama de productos diversa: Junyu ofrece una amplia gama de equipos para alimentos, incluidas máquinas para hacer galletas, máquinas para hacer dulces, máquinas para hacer chocolate y más, para satisfacer diversas necesidades de la industria alimentaria.

Maquinaria de alta calidad: Junyu se compromete a producir equipos de alta calidad, garantizando durabilidad, confiabilidad y eficiencia en los procesos de producción de alimentos.

Tecnología innovadora: Con un enfoque en la innovación, Junyu integra tecnología avanzada en sus máquinas, mejorando el rendimiento y la productividad de sus clientes.

Opciones de personalización: Junyu ofrece opciones de personalización para adaptar la maquinaria según los requisitos específicos del cliente, garantizando que cada máquina satisfaga las necesidades únicas de sus usuarios.

Conocimientos y experiencia: Con años de experiencia en la industria, Junyu ha desarrollado experiencia en la fabricación de equipos alimentarios, ofreciendo a los clientes productos confiables respaldados por el conocimiento de la industria.

Alcance global: Junyu tiene presencia global, atiende a clientes en todo el mundo y brinda soporte y servicio donde sea necesario.