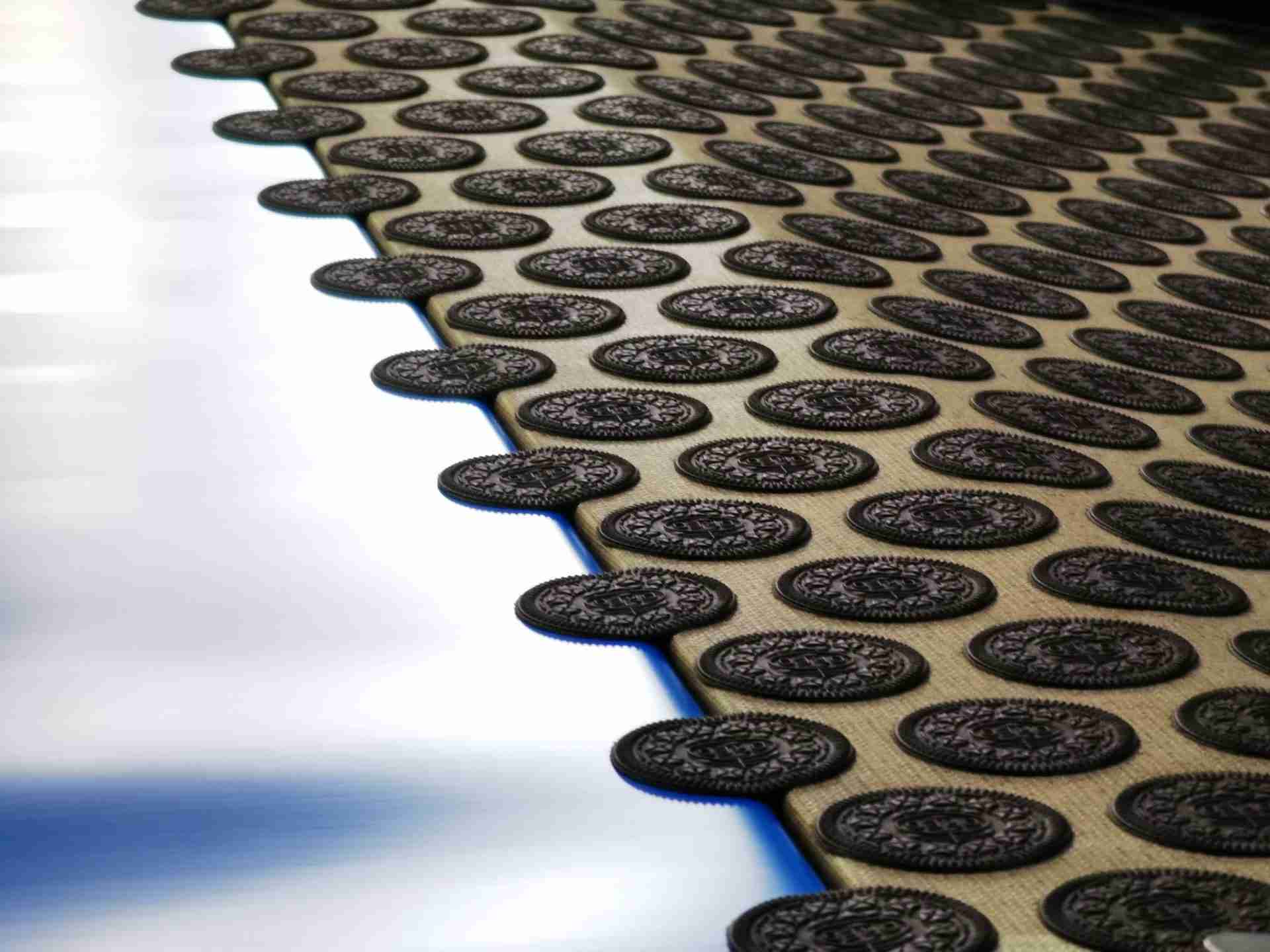

Soft biscuits are a type of biscuits made with oil, low-gluten flour, and sugar.This type of biscuit has a smooth taste, less gluten during dough preparation, and good plasticity and adhesionTherefore, Junyu recommends that customers use roller printing machines, which can increase the pattern anainterest of biscuits. Typical soft biscuits are Oreo, Digestive, caramel butter biscuits, oatmeal biscuits, etc.Machine principle: After horizontal dough mixing. The dough is directly transported to the forming machine forroller printing, there is a rubber roller under the belt to help crab the shapes. The raw biscuit can be directlypassed through the salt and sugar spreader then entering the oven for baking. Usually, the baking time requiredis shorter than hard biscuit.

| Modelo | JYB-280 | JYB-400 | JYB-600 | JYB-800 | JYB-1000 | JYB-1200 | JYB-1500 | Remark |

| Capacidad de producción (kg/h) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | Customized capacity |

| Oven Length(m) | 16 | 28 | 40 | 40 | 60 | 50 | 70 | Depend |

| Total length(m) | 29.6 | 64.5 | 85.5 | 92.5 | 125 | 125 | 150 | If No U Turn Conveyor |

| Baking temperature(C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ | 190-240℃ | 190-240℃ | 190-240C | Depend |

| Whole line power(kW) | 80 | 90 | 300 | 400 | 00 | 800 | 900 | If Use Electric Oven |

| LPG Oven(kg/h) | 10 | 20 | 35 | 45 | 60 | 70 | 80 | If Use LPG Oven |

| Whole line weight(kg) | 6000 | 12000 | 20000 | 28000 | 35000 | 45000 | 55000 | Approx |

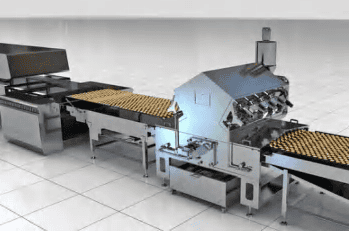

The production process begins with the preparation of raw materials such as flour, sugar, fats, and water. These ingredients are mixed in a dough mixer to form a uniform dough.

A high – efficiency dough mixer ensures that the dough is evenly mixed. This step is crucial for achieving the right consistency and texture for the biscuits.

A rotary moulder shapes the dough sheets into the desired biscuit forms. The moulder’s molds are designed to create a variety of shapes, including the classic digestive biscuit shape.

The biscuits are baked in a tunnel oven, which offers versatile heating options, including electricity and gas, for precise temperature control. The oven’s intelligent temperature control ensures even baking and a consistent product.

The biscuits are baked in a tunnel oven, which offers versatile heating options, including electricity and gas, for precise temperature control. The oven’s intelligent temperature control ensures even baking and a consistent product.

After baking, a spraying system applies a layer of oil to the biscuits. This step enhances the biscuits’ flavor and texture.

The biscuits are cooled on a cooling conveyor. This step is crucial for stabilizing the biscuits’ texture and ensuring they are ready for the next stage.

Finally, the biscuits are packaged using an automated packing system. This ensures they are neatly sealed and protected for distribution and sale

Fully automatic crisp digestive biscuit production lines are suitable for large – scale manufacturing facilities as well as smaller – scale production units. They can produce a wide range of biscuits, from traditional crisp digestives to more specialized and innovative products.

In summary, the fully automatic crisp digestive biscuit production line offers an efficient and reliable solution for high – quality biscuit production. Its precise control, versatile capabilities, energy – efficient operation, user – friendly interface, superior hygiene standards, customizable output, and cost – effective design make it an excellent choice for any business in the food manufacturing industry

**Act Now! Limited-Time Offer**

**Request a FREE Custom Quote Today!**

**Book a Live Demo: See the Line in Action!**

Question and Answer

Shortcake is a type of biscuit with a crumbly texture, while hard biscuit has a harder texture and is more resistant to chewing. Shortcake usually has a higher fat and sugar content, giving it a more crumbly structure. Hard biscuit, on the other hand, has a lower fat and sugar content, resulting in a firmer texture. The surface of shortcake often has raised pattern, while hard biscuit usually has concave round hole and a smoother appearance.

A cookie is a small, flat baked pastry that is typically sweet and can be made from various ingredients such as flour, sugar, and butter. Cookies can have different textures and flavors, ranging from soft and chewy to crispy and buttery.

Biscuits can be broadly classified into several types, including hard biscuit,soft iscuit, soda biscuits, and wafers.Soft biscuit has a harder texture and is more resistant to chewing,soft biscuit has a crumbly texture, soda biscuits are made from fermented dough and have a distinctive fermented flavor, and wafers are light and porous with less sugar and fat.

Rotary Rack Ovens: Designed for high-volume baking operations with a rotating rack system to ensure even baking.

Tunnel Ovens: Specialized ovens for continuous, high-volume production. Products move through the oven on a conveyor belt.

Electric tunnel ovens use the Joule effect to generate heat. They are simple to operate and maintain, and can heat separate zones to different temperatures. They are highly efficient, with no emissions, and offer precise temperature control.

Infrared technology can be used in ovens and can be powered by either gas or electricity. It transfers thermal energy in the form of electromagnetic waves and is effective for surface browning, drying, curing, and melting product toppings

Natural gas is one of the most common energy sources for tunnel ovens. It offers good temperature control, flexibility, and is clean and hygienic in operation.

LPG is portable and versatile, making it suitable for areas without natural gas infrastructure. It has a higher energy density than natural gas and offers similar benefits in terms of temperature control and flexibility

The initial cost of gas ovens may be higher than electric ovens, but they offer low operating costs and quick heating

Diesel fuel is less common but can be used in areas where natural gas or LPG are not available.

Fuel oil is sometimes used in areas where natural gas or LPG are not available. It is relatively inexpensive but produces higher emissions compared to natural gas or LPG

Hybrid tunnel ovens combine different heating technologies, such as direct-fired convection and indirect convection, offering the benefits of multiple heating methods in a single machine. This allows for greater flexibility and better product quality