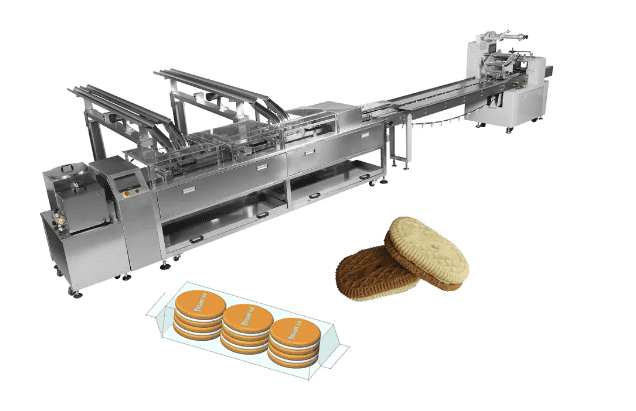

La capacidad de producción varía según los modelos: las líneas pequeñas totalmente automáticas pueden producir entre 100 y 800 kg/h, mientras que las grandes pueden manejar entre 800 y 1500 kg/h. La disposición puede ajustarse en función del espacio disponible, añadiendo secciones giratorias según sea necesario.

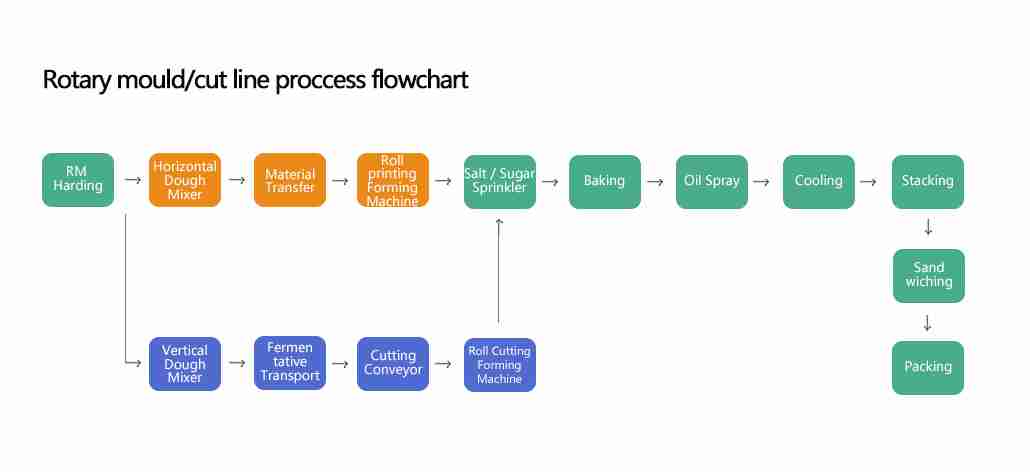

El equipo presenta un diseño novedoso y compacto con un alto grado de automatización. Automatiza completamente el proceso, desde la alimentación hasta el laminado, el moldeado, el reciclaje de residuos, el secado, el rociado de aceite y el enfriamiento.

Puede producir varios tipos de galletas, tanto blandas como duras. Cambiando los moldes y ajustando las recetas, puede crear galletas premium populares como galletas de nata, de sándwich, de soda, con forma de animal y de verduras.

Jy Company ofrece una amplia gama de moldes y fórmulas de procesamiento para los clientes.

| Modelo(pequeño y mediano) | JYB-280 | JYB-400 | JYB-600 | JYB-800 |

| Capacidad de producción (kg/h) | 100 | 250 | 500 | 750 |

| Longitud del horno (m) | 16 | 28 | 40 | 40 |

| Espacio de fábrica necesario (m) | 5×25 | 10×40 | 15×50 | 15×50 |

| Temperatura de cocción(C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ |

| Potencia total de la línea (kW) | 80 | 90 | 300 | 400 |

| Horno GLP (kg/h) | 10 | 20 | 35 | 45 |

| Peso de toda la línea (kg) | 6000 | 12000 | 20000 | 28000 |

Capacidad :

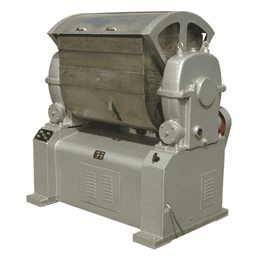

Mezclador de harina:

La mezcladora de harina se utiliza para mezclar harina con otros ingredientes secos como azúcar y levadura en polvo, creando una mezcla seca homogénea que sirve de base para la producción de galletas.

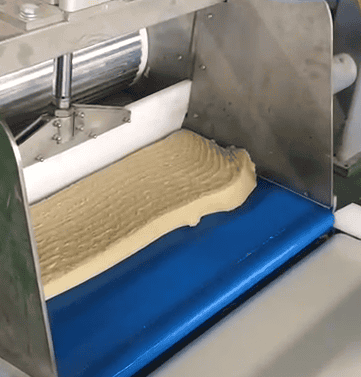

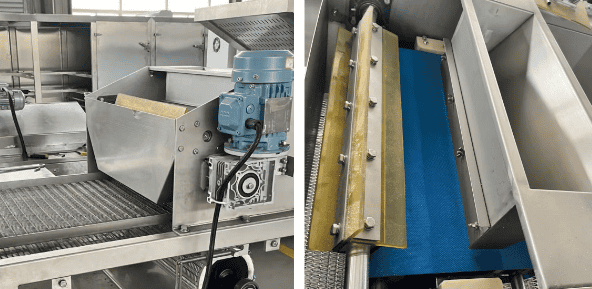

Corte y transporte de la masa:

Este componente corta la masa en trozos uniformes y los transporta a la siguiente fase de producción, garantizando un calibrado uniforme y un flujo de trabajo eficaz.

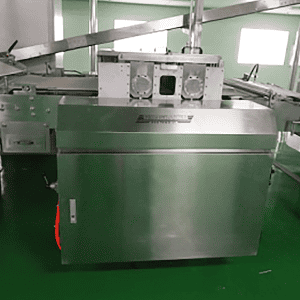

Moldeadora rotativa (galleta blanda):

La moldeadora rotativa da la forma deseada a la masa de galletas blandas mediante moldes giratorios, ideal para producir galletas de textura blanda con forma y tamaño uniformes.

Cortador giratorio (galleta de masa dura):

Diseñado para galletas de masa dura, este equipo corta la masa en formas precisas y uniformes, garantizando bordes limpios y una calidad constante del producto.

Espolvorear con sal y azúcar:

Esta máquina distribuye uniformemente la sal y el azúcar sobre los trozos de masa, realzando el sabor y añadiendo un toque final antes de hornear.

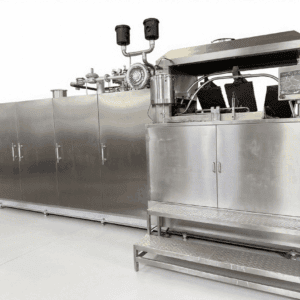

Horno de túnel:

El horno de túnel, equipado para funcionar con electricidad, GLP o gasóleo, cuece las galletas a medida que pasan por una cinta transportadora, lo que garantiza una cocción uniforme y una producción eficiente.

180o Giro en U:

El mecanismo de giro de 180/90 grados permite reordenar eficazmente las galletas en la cinta transportadora, facilitando las transiciones fluidas entre las distintas fases de producción.

Apilado de galletas:

Este equipo apila galletas horneadas de forma eficiente, preparándolas para procesos posteriores como el envasado o el tratamiento posterior.

Máquina sandwichadora de galletas de nata:.

Rellena de crema entre dos capas de galletas, creando galletas de sándwich con una aplicación precisa de la crema y garantizando un producto delicioso y uniformemente relleno.

Preguntas y respuestas

El bizcocho es un tipo de galleta de textura desmenuzable, mientras que el bizcocho duro tiene una textura más dura y es más resistente a la masticación. El bizcocho suele tener un mayor contenido en grasa y azúcar, lo que le confiere una estructura más desmenuzable. El bizcocho duro, en cambio, tiene un menor contenido en grasa y azúcar, lo que le confiere una textura más firme. La superficie de la tarta suele presentar relieves, mientras que la de la galleta dura suele ser cóncava y redondeada, con un aspecto más liso.

Una galleta es una masa horneada pequeña y plana que suele ser dulce y puede elaborarse con diversos ingredientes, como harina, azúcar y mantequilla. Las galletas pueden tener diferentes texturas y sabores, desde blandas y masticables hasta crujientes y mantecosas.

La galleta blanda tiene una textura más dura y es más resistente a la masticación, la galleta blanda tiene una textura desmenuzable, la galleta de soda se elabora con masa fermentada y tiene un sabor fermentado característico, y los barquillos son ligeros y porosos, con menos azúcar y grasa.

Hornos de cremallera: Diseñado para operaciones de horneado de gran volumen con un sistema de rejilla giratoria para garantizar un horneado uniforme.

Hornos de túnel: Hornos especializados para la producción continua de grandes volúmenes. Los productos se desplazan por el horno sobre una cinta transportadora.

Los hornos túnel eléctricos utilizan el efecto Joule para generar calor. Son fáciles de manejar y mantener, y pueden calentar zonas separadas a diferentes temperaturas. Son muy eficientes, no producen emisiones y ofrecen un control preciso de la temperatura.

La tecnología de infrarrojos puede utilizarse en hornos alimentados por gas o electricidad. Transfiere energía térmica en forma de ondas electromagnéticas y es eficaz para dorar superficies, secar, curar y fundir coberturas de productos.

El gas natural es una de las fuentes de energía más comunes para los hornos de túnel. Ofrece un buen control de la temperatura, flexibilidad y un funcionamiento limpio e higiénico.

El GLP es portátil y versátil, por lo que resulta adecuado para zonas sin infraestructura de gas natural. Tiene mayor densidad energética que el gas natural y ofrece ventajas similares en cuanto a control de temperatura y flexibilidad.

El coste inicial de los hornos de gas puede ser superior al de los hornos eléctricos, pero ofrecen bajos costes de funcionamiento y un calentamiento rápido

El gasóleo es menos común, pero puede utilizarse en zonas donde no se disponga de gas natural o GLP.

El fuelóleo se utiliza a veces en zonas donde no se dispone de gas natural o GLP. Es relativamente barato, pero produce más emisiones que el gas natural o el GLP.

Los hornos de túnel híbridos combinan distintas tecnologías de calentamiento, como la convección por fuego directo y la convección indirecta, ofreciendo las ventajas de varios métodos de calentamiento en una sola máquina. Esto permite una mayor flexibilidad y una mejor calidad del producto

| Modelo(pequeño y mediano) | JYB-280 | JYB-400 | JYB-600 | JYB-800 |

| Capacidad de producción (kg/h) | 100 | 250 | 500 | 50 |

| Longitud del horno (m) | 16 | 28 | 40 | 40 |

| Espacio de fábrica necesario (m) | 5×25 | 10×40 | 15×50 | 15×50 |

Junyu tiene más capacidad y máquinas más grandes para elegir.