Last Updated on 24 May, 2024 by jymachinetech

Many people do not know how to properly maintain and maintain the bakery equipment. If the bakery equipment is not maintained for a long time, it is easy to cause a safety accident.

The daily maintenance of gas equipment is an important project to reduce lost work, continue production, complete tasks with quality and quantity, and improve food safety. Enterprises use the three-level maintenance system to the greatest extent in equipment maintenance. Existing maintenance, primary maintenance and secondary maintenance systems. maintain.

This is essential. Any negligence will lead to unforeseen consequences, food trivial matters, so a targeted professional maintenance system is the ideal prevention method and measure at present. Routine maintenance refers to personnel operation. For the daily maintenance of fermented food equipment, the maintenance items are mainly concentrated on the outside of the equipment, and the main contents are equipment cleaning, lubrication, tightening, etc.

Before and after the observation shift, each part of the oven should be carefully inspected, and different auxiliary devices used by the production enterprise to increase or decrease the output should be operated. Check the heat of the oven stove. Clean all parts and components of the oven and keep them tidy. Clean. Remove the debris from the product on the stove belt. Check and clean the lubrication point, lubricate and lubricate, remove the oil phenomenon. There are screws and nuts everywhere, and the texture is reliable. Clean teeth, check and adjust electrical. The device keeps its movements sensitive and reliable. Clean the furnace wall and external wall protection, drive the appearance of hair, clean oil stains, gray and yellow robe, and clean the oven as a whole

Why Choose Us?

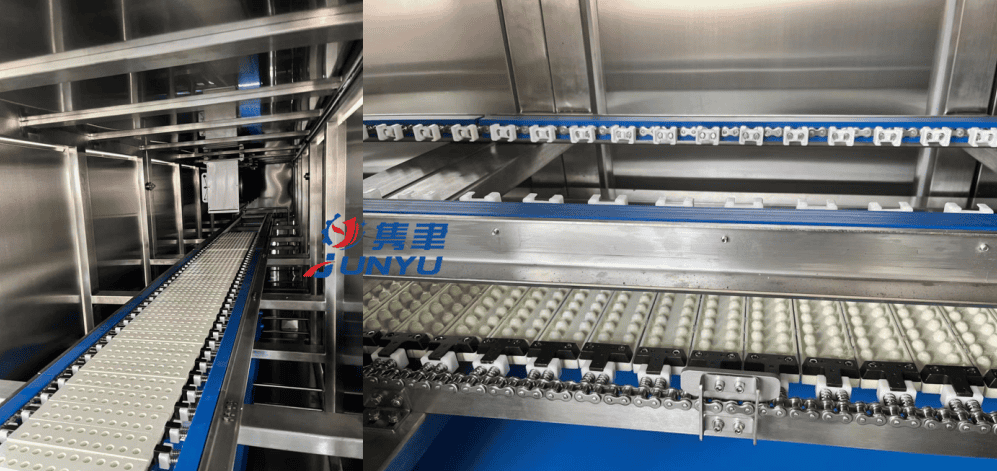

Shanghai Junyu started as a food equipment manufacturer specializing in various types of machinery for the food industry. Our range includes biscuit making machines, candy making machines, chocolate making machines, wafer making machines, cake making machines, packaging machines, and more. With a commitment to quality and innovation, we strive to provide top-notch equipment to meet the diverse needs of our customers in the food manufacturing sector.

Diverse Product Range: Junyu offers a wide range of food equipment, including biscuit making machines, candy making machines, chocolate making machines, and more, catering to various needs in the food industry.

High-Quality Machinery: Junyu is committed to producing high-quality equipment, ensuring durability, reliability, and efficiency in food production processes.

Innovative Technology: With a focus on innovation, Junyu integrates advanced technology into its machines, enhancing performance and productivity for its customers.

Customization Options: Junyu provides customization options to tailor machinery according to specific customer requirements, ensuring that each machine meets the unique needs of its users.

Expertise and Experience: With years of experience in the industry, Junyu has developed expertise in food equipment manufacturing, offering customers reliable products backed by industry knowledge.

Global Reach: Junyu has a global presence, serving customers worldwide and providing support and service wherever needed.