Последнее обновление: 14 июня 2024 г. пользователем jymachinetech

Hello, future confectionery captain! Are you on the quest to find the right gummy manufacturing machine to be the heart of your candy-making voyage?

Whether you’re setting sail in the gummy sea for the first time or you’re a seasoned skipper looking to upgrade your fleet, choosing the right machine is a decision as sweet and critical as the gummies you’ll produce.

Let’s navigate the waters of machinery selection together and discover how to choose the right gummy manufacturing machine for your business.

1. Define Your Gummy Vision

Before you start comparing machines, it’s essential to have a clear vision of what you want to achieve with your gummies. Are you dreaming of creating classic gummy bears or venturing into the realm of gummy dinosaurs and spaceships? Do you want to produce a wide variety of shapes and flavors, or do you plan to specialize? Your vision will guide the type of machine you’ll need.

2. Assess Your Production Needs

Understanding your production needs is like checking the weather forecast before you set sail. Do you need a machine for small-batch production, or are you aiming for mass production that could supply a galaxy of gummy fans? The size of your operation and your production goals will significantly influence the machine’s capacity and capabilities you should look for.

3. Consider the Machine’s Size and Space

When choosing a machine, size does matter – both in terms of the machine’s physical dimensions and its output capacity. Make sure you have enough space in your factory to accommodate the machine and allow for smooth operation. And remember, a bigger machine doesn’t always mean better; it’s about finding the right fit for your business.

4. Automation and Labor Efficiency

Automation is the not-so-secret weapon of modern gummy production. A machine that offers a higher level of automation can significantly reduce labor costs and increase efficiency. Consider how much automation you need and whether you’re ready to invest in a more advanced system.

5. Quality and Consistency

The hallmark of a great gummy manufacturer is the ability to produce gummies with consistent quality, batch after batch. Look for machines that have a reputation for delivering on this promise, with features like precise ingredient measurement, uniform mixing, and accurate temperature control.

6. Flexibility and Customization

In the ever-changing world of confectionery, flexibility is key. A machine that allows for easy changes in recipes, flavors, and colors will keep you agile and able to adapt to market demands and trends.

7. Energy Efficiency and Cost of Operation

Running a gummy manufacturing machine can be as energy-intensive as a space mission. Look for energy-efficient models that can reduce your operational costs and environmental impact.

8. Соблюдение правил

Make sure the machine you choose complies with all relevant food safety and industry regulations. This will save you from any legal headaches down the road and ensure that your gummies are safe for consumption.

9. The Manufacturer’s Reputation and Support

A good machine is only as good as the company that stands behind it. Consider the manufacturer’s reputation, their after-sales service, and the support they provide. A reputable manufacturer will offer training, maintenance, and technical support to keep your machine running smoothly.

10. Machine Reliability and Durability

You want a machine that’s built to last, not one that will break down after a few batches of gummies. Look for machines made with high-quality materials and a design that can withstand the rigors of daily use.

11. Training and Ease of Operation

A machine that’s easy to operate and maintain will save you time and reduce the likelihood of errors. Ensure that the machine’s control systems are user-friendly and that training is available for your staff.

12. Scalability and Future Growth

As your business grows, your gummy machine should be able to grow with you. Consider whether the machine can be scaled up or if additional machines can be integrated into your production line as needed.

13. Financing and Return on Investment (ROI)

Investing in a gummy manufacturing machine is a significant financial decision. Consider the cost of the machine, the financing options available, and the potential return on investment. A good machine will pay for itself over time through increased production and efficiency.

14. Trial Runs and Demonstrations

If possible, ask the manufacturer for a trial run or a demonstration of the machine in action. This will give you a firsthand look at the machine’s capabilities and help you determine if it meets your production needs.

15. After-Sales Service and Maintenance

The life of your machine doesn’t end with the purchase. A good after-sales service and maintenance plan will ensure that your machine stays in top condition and is quickly repaired if any issues arise.

16. Customization Options

Every gummy manufacturer has unique needs. Look for machines that offer customization options, such as different mold sets, flavor injectors, or specialized coating equipment, to suit your specific production requirements.

17. Industry Trends and Innovations

The confectionery industry is always evolving. Stay informed about the latest trends and innovations in gummy manufacturing to ensure that the machine you choose can keep up with the times and help you stay competitive.

18. Reviews and Recommendations

Don’t be shy about asking for recommendations from other gummy manufacturers or reading reviews online. The experiences of others can provide valuable insights into the performance and reliability of different machines.

19. Your Intuition

Sometimes, choosing the right machine comes down to a gut feeling. Trust your intuition and choose the machine that feels right for your business and your gummy vision.

Заключение

Choosing the right gummy manufacturing machine is a decision as unique as your business itself. By considering factors like production needs, machine size, automation, quality, energy efficiency, and the manufacturer’s support, you can find the perfect partner for your gummy-making journey. Remember, the right machine is out there, waiting to help you create gummies that are out of this world. So, happy choosing, and may your gummy business be as sweet and successful as the treats you produce!

Помнить: When it comes to selecting a gummy manufacturing machine, it’s not just about finding a machine; it’s about finding a partner that will help you grow your business and achieve your gummy dreams. Keep your eyes peeled for that machine that checks all the boxes and feels like the cherry on top of your gummy sundae!

Почему выбрали нас?

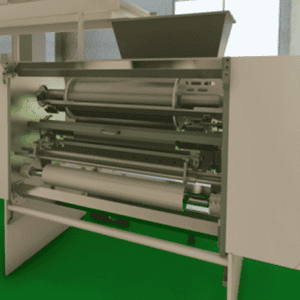

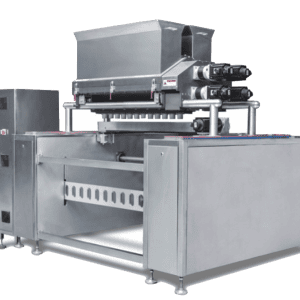

Компания Shanghai Junyu начинала свою деятельность как производитель пищевого оборудования, специализирующийся на различных типах оборудования для пищевой промышленности. В наш ассортимент входят машины для изготовления печенья, машины для производства конфет, машины для производства шоколада, машины для изготовления вафель, машины для изготовления тортов, упаковочные машины и многое другое. Придерживаясь качества и инноваций, мы стремимся предоставлять первоклассное оборудование для удовлетворения разнообразных потребностей наших клиентов в секторе производства продуктов питания.

Разнообразный ассортимент продукции: Junyu предлагает широкий ассортимент пищевого оборудования, в том числе машины для изготовления печенья, машины для производства конфет, машины для производства шоколада и многое другое, удовлетворяющее различные потребности пищевой промышленности.

Высококачественное оборудование: Junyu стремится производить высококачественное оборудование, обеспечивающее долговечность, надежность и эффективность процессов производства продуктов питания.

Инновационные технологии: Делая акцент на инновациях, Junyu интегрирует передовые технологии в свои машины, повышая производительность и производительность своих клиентов.

Параметры настройки: Junyu предоставляет возможности настройки оборудования в соответствии с конкретными требованиями клиентов, гарантируя, что каждая машина отвечает уникальным потребностям своих пользователей.

Экспертиза и опыт: Благодаря многолетнему опыту работы в отрасли компания Junyu накопила знания в области производства пищевого оборудования, предлагая клиентам надежную продукцию, подкрепленную отраслевыми знаниями.

Глобальный охват: Junyu присутствует по всему миру, обслуживая клиентов по всему миру и обеспечивая поддержку и обслуживание там, где это необходимо.