Кто мы

О Цзюньюй

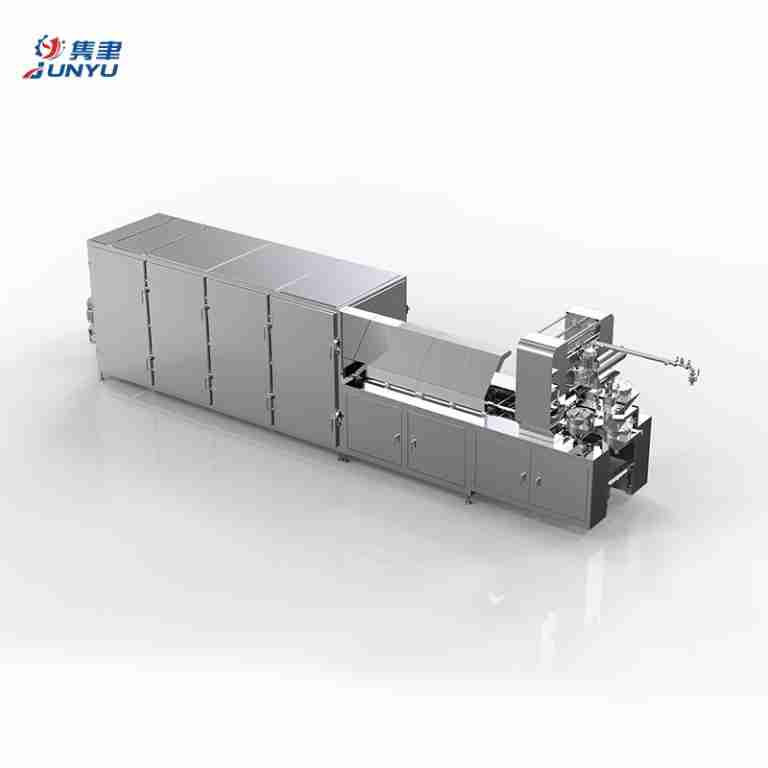

Цзюньюй является профессиональным производителем пищевого оборудования, такого какмашины для производства печенья, Линия по производству тортов, Конфеты Гамми, Линия по производству мармеладных конфетЛиния по производству печенья, оборудование для производства снеков и т.д. Мы работаем в этой сфере уже более 30 лет. Наша продукция хорошо продается по всему миру и пользуется хорошей репутацией среди наших клиентов.

Наша компания прошла сертификацию системы управления качеством ISO9001:2008, а также является одним из центральных предприятий Китайской ассоциации производителей оборудования для приготовления пищи (CFPEA).

Мы хотим подружиться с вами благодаря нашей высококачественной продукции и искреннему сервису.

Категории продуктов

02.

02. Линия для производства конфет

03.

03. Линия для производства шоколада

04.

04. Машина для упаковки продуктов питания

05.

05. Линия по производству поппинг-боба

06.

06. Линия для производства тортов

Цзюньюй

Наши услуги

Высококачественное производство пищевого оборудования

Компания Junyu специализируется на разработке и производстве высококлассного пищевого оборудования, в том числе систем для производства жевательных конфет, линий для производства печенья, оборудования для производства тортов и оборудования для производства закусок. Благодаря более чем 30-летнему опыту работы в отрасли мы гарантируем, что каждый поставляемый нами продукт отвечает самым высоким стандартам качества и эффективности.

Глобальная дистрибуция и репутация

Наше пищевое оборудование пользуется доверием и продается по всему миру, завоевав репутацию надежного и инновационного производителя. Где бы вы ни находились, Junyu гарантирует, что наша продукция будет отвечать потребностям клиентов в разных регионах, обеспечивая неизменное качество и производительность.

ISO9001:2008 Сертифицированный менеджмент качества

Компания Junyu стремится поддерживать высочайшие стандарты качества производства. Вся продукция - от оборудования для производства жевательных конфет до передовых линий по производству печенья - сертифицирована в соответствии с системой управления качеством ISO9001:2008, что гарантирует точность изготовления и долговечность работы.

Всесторонняя поддержка клиентов

Мы стремимся обеспечить исключительное обслуживание клиентов. От предпродажной консультации до послепродажной поддержки - наша команда Junyu всегда готова помочь вам на каждом этапе покупки. Если вам нужна техническая помощь или рекомендации по использованию продукта, мы всегда готовы помочь.

Лидерство и сотрудничество в отрасли

Будучи одним из центральных предприятий Китайской ассоциации производителей оборудования для приготовления пищи (CFPEA), компания Junyu играет активную роль в формировании индустрии пищевого оборудования. Мы сотрудничаем с другими лидерами в этой области, чтобы наша продукция была не только инновационной, но и соответствовала последним отраслевым стандартам и тенденциям.

Индивидуальные решения для вашего бизнеса

Мы понимаем, что у каждого предприятия есть свои уникальные потребности. Junyu предлагает индивидуальные решения в области пищевого оборудования, отвечающие вашим конкретным производственным требованиям. Если вам нужна система для производства жевательных конфет, линия для производства печенья, машина для производства тортов или оборудование для производства снеков, наша команда экспертов вместе с вами создаст идеальное решение для вашего предприятия.

Цзюньюй

Конфеты Gummy машина и печенье производственной линии машины

Простое управление Доступная цена Температурная настройка Сервопривод депонирования PLC регулируемый...

Благодаря интеграции передовых технологий и оптимизированных процессов эта линия помогает...

Цзюньюй

Наши клиенты