Высокая степень автоматизации: Сокращает ручной труд и повышает эффективность производства.

Разнообразные продукты: Меняя формы и рецепты, можно производить печенье с мишками разных форм и вкусов.

Энергоэффективность: Оснащен энергосберегающими технологиями для снижения эксплуатационных расходов.

Гигиенический дизайн: Используются материалы пищевого класса и легко очищаемые конструкции, отвечающие стандартам безопасности пищевых продуктов.

Пользователь - дружелюбный: Интуитивно понятная система управления обеспечивает простоту эксплуатации и контроля.

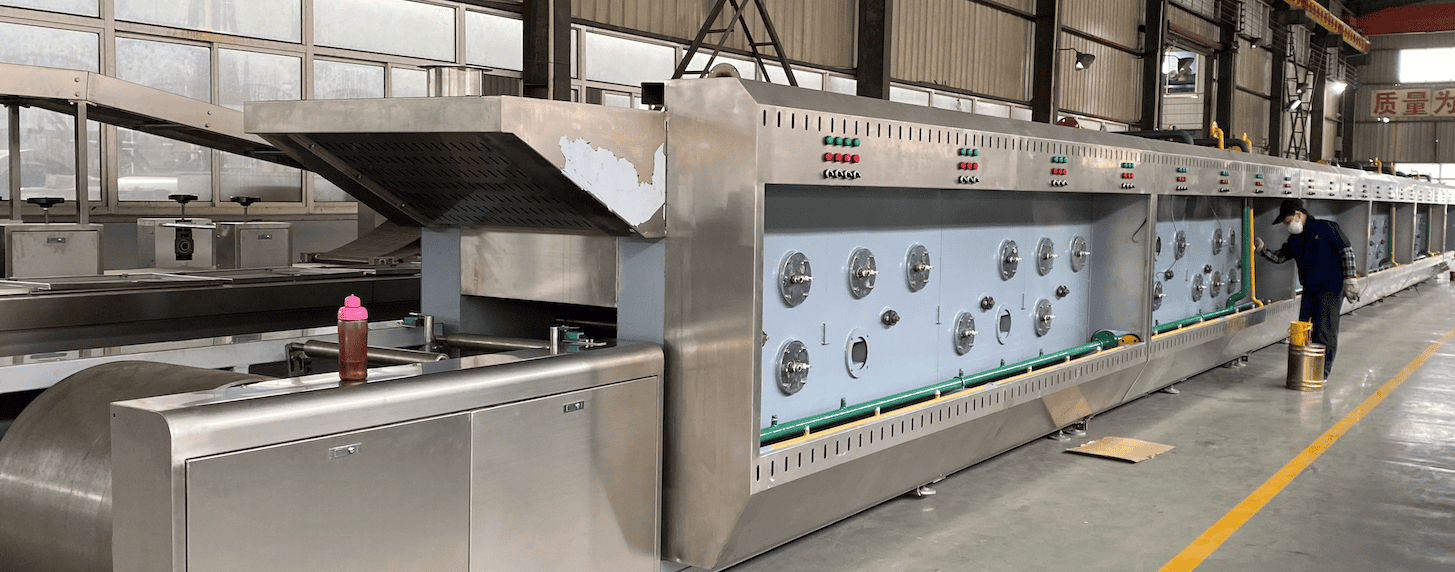

| Модель | JYB-280 | JYB-400 | JYB-600 | JYB-800 | JYB-1000 | JYB-1200 | JYB-1500 | Ремарка |

| Производительность (кг/ч) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | Индивидуальная производительность |

| Длина печи (м) | 16 | 28 | 40 | 40 | 60 | 50 | 70 | Зависимость |

| Общая длина (м) | 29.6 | 64.5 | 85.5 | 92.5 | 125 | 125 | 150 | Если нет U-образного поворота конвейера |

| Температура выпечки (C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ | 190-240℃ | 190-240℃ | 190-240C | Зависимость |

| Мощность всей линии (кВт) | 80 | 90 | 300 | 400 | 00 | 800 | 900 | Если используется электрическая духовка |

| Печь на сжиженном газе (кг/ч) | 10 | 20 | 35 | 45 | 60 | 70 | 80 | При использовании печи на сжиженном газе |

| Вес всей линии (кг) | 6000 | 12000 | 20000 | 28000 | 35000 | 45000 | 55000 | Приблизительно |

Процесс начинается с работы тестомеса, который эффективно смешивает муку, сахар, жиры и другие ингредиенты для получения однородного теста. Благодаря этому тесто приобретает нужную консистенцию для формирования печенья в виде мишек.

Если того требует рецепт, тесто подвергается процессу брожения. Этот этап очень важен для формирования текстуры и вкуса теста, что делает его более приятным для употребления.

С помощью специализированной печатной машины на тесто наносятся различные рисунки. Это придает печенью с мишками визуальную привлекательность и характер, делая его более привлекательным для покупателей.

Роторный резак придает тесту легендарную форму мишки. Благодаря точности и эффективности эта машина обеспечивает равномерную форму каждого печенья, что позволяет получить однородный продукт.

Печенье с мишками проходит через туннельную печь, которая может нагреваться от электричества, газа или других видов топлива. Точный контроль температуры в печи обеспечивает равномерное пропекание, придавая печенью золотистый цвет и восхитительный вкус.

После выпечки бисквиты переходят на станцию шоколадной начинки. Здесь машина для наполнения впрыскивает в печенье шоколад или другую начинку, придавая ему дополнительный вкус и удовольствие.

Наконец, наполненное печенье с мишками упаковывается с помощью автоматизированной упаковочной системы. Таким образом, они аккуратно запечатываются и защищаются для распространения и продажи.