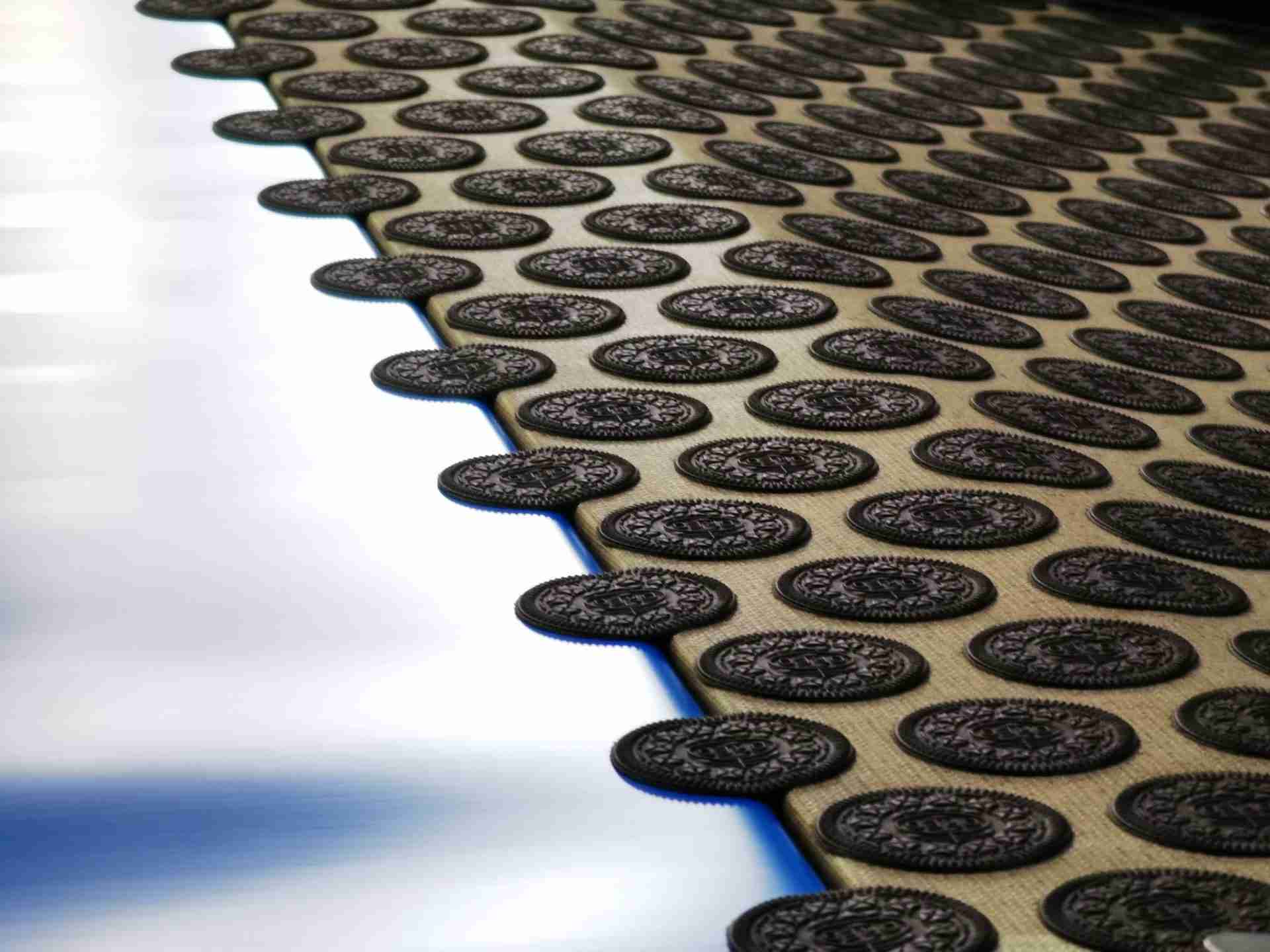

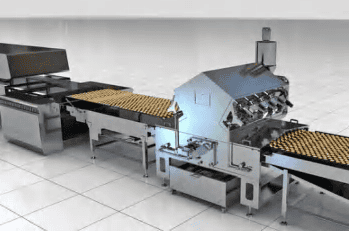

Esse tipo de biscoito tem um sabor suave, menos glúten durante a preparação da massa e boa plasticidade e aderência. Por isso, a Junyu recomenda que os clientes usem máquinas de impressão de rolos, que podem aumentar o padrão e o interesse dos biscoitos. Os biscoitos macios típicos são Oreo, Digestive, biscoitos de manteiga com caramelo, biscoitos de aveia, etc. Princípio da máquina: Após a mistura horizontal da massa. A massa é transportada diretamente para a máquina de moldagem para impressão em rolo, há um rolo de borracha sob a correia para ajudar a criar as formas. O biscoito cru pode ser passado diretamente pelo espalhador de sal e açúcar e, em seguida, entrar no forno para assar. Normalmente, o tempo de cozimento necessário é menor do que o do biscoito duro.

| Modelo | JYB-280 | JYB-400 | JYB-600 | JYB-800 | JYB-1000 | JYB-1200 | JYB-1500 | Observação |

| Capacidade de produção (kg/h) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | Capacidade personalizada |

| Comprimento do forno (m) | 16 | 28 | 40 | 40 | 60 | 50 | 70 | Depender |

| Comprimento total (m) | 29.6 | 64.5 | 85.5 | 92.5 | 125 | 125 | 150 | Se não houver U Turn Conveyor |

| Temperatura de cozimento (C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ | 190-240℃ | 190-240℃ | 190-240C | Depender |

| Potência da linha inteira (kW) | 80 | 90 | 300 | 400 | 00 | 800 | 900 | Se estiver usando um forno elétrico |

| Forno a GLP (kg/h) | 10 | 20 | 35 | 45 | 60 | 70 | 80 | Se estiver usando um forno a GLP |

| Peso da linha inteira (kg) | 6000 | 12000 | 20000 | 28000 | 35000 | 45000 | 55000 | Aprox. |

O processo de produção começa com a preparação de matérias-primas, como farinha, açúcar, gorduras e água. Esses ingredientes são misturados em um misturador de massa para formar uma massa uniforme.

Um misturador de massa de alta eficiência garante que a massa seja misturada uniformemente. Essa etapa é fundamental para obter a consistência e a textura corretas para os biscoitos.

Um moldador rotativo molda as folhas de massa nos formatos de biscoito desejados. Os moldes do moldador são projetados para criar uma variedade de formatos, incluindo o clássico formato de biscoito digestivo.

Os biscoitos são assados em um forno túnel, que oferece opções versáteis de aquecimento, incluindo eletricidade e gás, para um controle preciso da temperatura. O controle inteligente de temperatura do forno garante um cozimento uniforme e um produto consistente.

Os biscoitos são assados em um forno túnel, que oferece opções versáteis de aquecimento, incluindo eletricidade e gás, para um controle preciso da temperatura. O controle inteligente de temperatura do forno garante um cozimento uniforme e um produto consistente.

Após o cozimento, um sistema de pulverização aplica uma camada de óleo aos biscoitos. Essa etapa aprimora o sabor e a textura dos biscoitos.

Os biscoitos são resfriados em uma esteira de resfriamento. Essa etapa é fundamental para estabilizar a textura dos biscoitos e garantir que eles estejam prontos para a próxima etapa.

Por fim, os biscoitos são embalados por meio de um sistema de empacotamento automatizado. Isso garante que eles sejam cuidadosamente selados e protegidos para distribuição e venda

As linhas de produção de biscoitos digestivos crocantes totalmente automáticas são adequadas para instalações de fabricação em grande escala, bem como para unidades de produção em menor escala. Elas podem produzir uma ampla variedade de biscoitos, desde os tradicionais digestivos crocantes até produtos mais especializados e inovadores.

Em resumo, a linha de produção de biscoitos digestivos crocantes totalmente automática oferece uma solução eficiente e confiável para a produção de biscoitos de alta qualidade. O controle preciso, os recursos versáteis, a operação com eficiência energética, a interface amigável, os padrões de higiene superiores, a produção personalizável e o design econômico fazem dela uma excelente opção para qualquer empresa do setor de fabricação de alimentos

**Aja agora! Oferta por tempo limitado**

**Solicite um orçamento personalizado GRATUITO hoje mesmo!

**Reserve uma demonstração ao vivo: Veja a linha em ação!

Perguntas e respostas

Shortcake é um tipo de biscoito com uma textura quebradiça, enquanto o biscoito duro tem uma textura mais dura e é mais resistente à mastigação. O shortcake geralmente tem um teor mais alto de gordura e açúcar, o que lhe confere uma estrutura mais quebradiça. O biscoito duro, por outro lado, tem um teor menor de gordura e açúcar, resultando em uma textura mais firme. A superfície do shortcake geralmente tem um padrão em relevo, enquanto o biscoito duro geralmente tem um buraco redondo côncavo e uma aparência mais lisa.

Um cookie é uma massa pequena, plana e assada, geralmente doce, que pode ser feita com vários ingredientes, como farinha, açúcar e manteiga. Os cookies podem ter diferentes texturas e sabores, variando de macios e mastigáveis a crocantes e amanteigados.

Os biscoitos podem ser amplamente classificados em vários tipos, incluindo biscoito duro, biscoito macio, biscoito de soda e wafers. O biscoito macio tem uma textura mais dura e é mais resistente à mastigação, o biscoito macio tem uma textura quebradiça, os biscoitos de soda são feitos de massa fermentada e têm um sabor fermentado característico, e os wafers são leves e porosos com menos açúcar e gordura.

Fornos de rack rotativo: Projetado para operações de cozimento de alto volume com um sistema de prateleiras rotativas para garantir um cozimento uniforme.

Fornos de túnel: Fornos especializados para produção contínua e de alto volume. Os produtos passam pelo forno em uma esteira transportadora.

Os fornos elétricos de túnel usam o efeito Joule para gerar calor. Eles são simples de operar e manter, e podem aquecer zonas separadas a diferentes temperaturas. São altamente eficientes, sem emissões, e oferecem controle preciso da temperatura.

A tecnologia de infravermelho pode ser usada em fornos e pode ser alimentada por gás ou eletricidade. Ela transfere energia térmica na forma de ondas eletromagnéticas e é eficaz para dourar superfícies, secar, curar e derreter coberturas de produtos

O gás natural é uma das fontes de energia mais comuns para fornos de túnel. Ele oferece bom controle de temperatura, flexibilidade e é limpo e higiênico na operação.

O GLP é portátil e versátil, o que o torna adequado para áreas sem infraestrutura de gás natural. Ele tem uma densidade de energia maior do que o gás natural e oferece benefícios semelhantes em termos de controle de temperatura e flexibilidade

O custo inicial dos fornos a gás pode ser mais alto do que o dos fornos elétricos, mas eles oferecem baixos custos operacionais e aquecimento rápido

O diesel é menos comum, mas pode ser usado em áreas onde não há disponibilidade de gás natural ou GLP.

O óleo combustível às vezes é usado em áreas onde não há disponibilidade de gás natural ou GLP. Ele é relativamente barato, mas produz emissões mais altas em comparação com o gás natural ou o GLP

Os fornos de túnel híbridos combinam diferentes tecnologias de aquecimento, como convecção direta e convecção indireta, oferecendo os benefícios de vários métodos de aquecimento em uma única máquina. Isso permite maior flexibilidade e melhor qualidade do produto