Exploring What a Biscuit Machine Is and How It Works

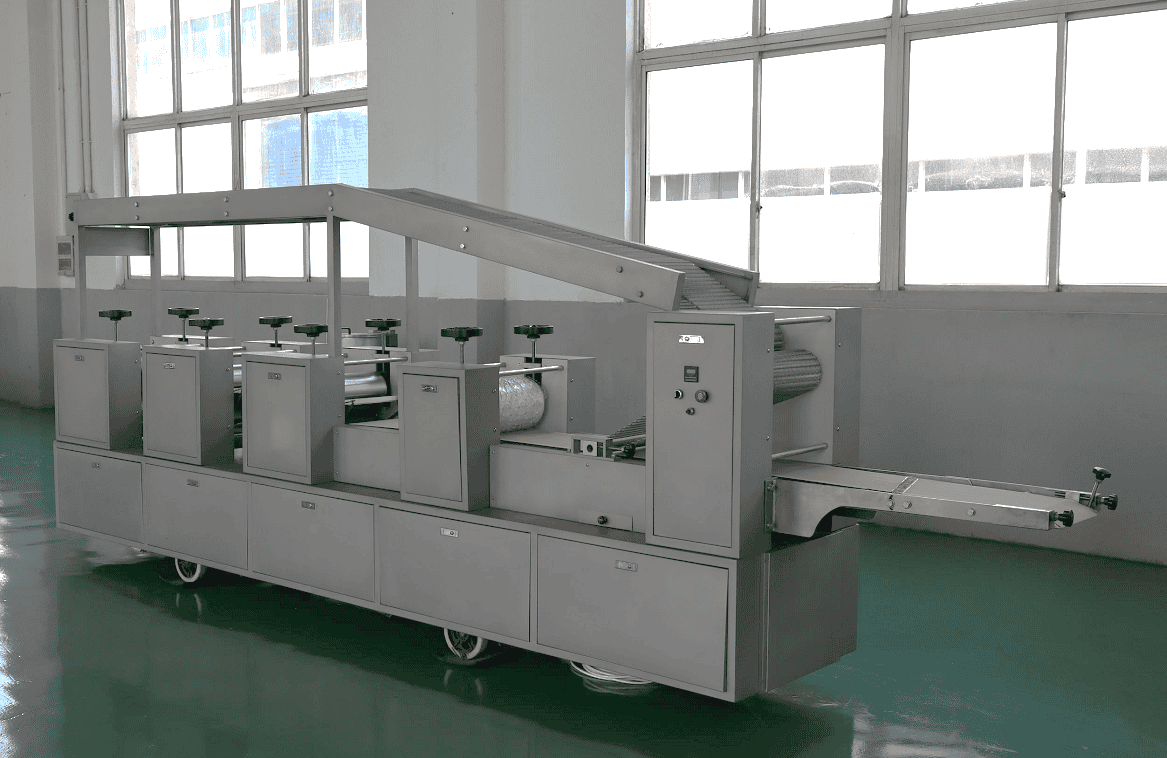

A biscuit machine automates mixing, shaping, baking, and packaging to produce consistent, high-quality biscuits efficiently in bakeries and factories.

Welcome to our Gummy & Biscuit Manufacturing Tutorial! Discover step-by-step guides, equipment insights, ingredient essentials, quality control tips, packaging best practices, regulatory information, and marketing strategies. Perfect for entrepreneurs and manufacturers aiming to master gummy and biscuit production. Join us to create delicious and high-quality treats with confidence and expertise!

A biscuit machine automates mixing, shaping, baking, and packaging to produce consistent, high-quality biscuits efficiently in bakeries and factories.

How to Make Cookies: The Ultimate Guide for Delicious Batches Introduction to Cookie Making Learn the basics of cookie making,

The Best Machine Gummy Candy Solutions for Efficient Production Introduction to the Industry The confectionery industry offers endless possibilities in

The Best Biscuit Machine for Efficient Production and Quality Cookies Introduction to Biscuit Production Our biscuit machines are designed for

Top Gummy Candy Machine for Efficient Production and Quality Results Introduction to Gummy Production The gummy production process involves creating

Complete Guide to Hard Dough Biscuit Production Line for UK Food Manufacturers Revolutionising Biscuit Manufacturing with Advanced Production Solutions The

The Best Biscuit Production Line: Efficiency and Design Considerations for UK Manufacturers The UK biscuit industry is experiencing unprecedented growth,

The Best Biscuit Machine for Efficient Production and Quality Results Introduction to Biscuit Machines Biscuit machines are designed to produce

Essential Insights on Biscuit Production Line Efficiency and Design Introduction to Biscuit Production A biscuit production line consists of various

The Best Biscuit Machine for Perfectly Baked Treats Every Time Introduction to Biscuit Machines A biscuit machine is a vital

Today, I would like to recommend the British McVitie’s Jaffa Cakes to everyone. It’s not only because McVitie’s cakes are

Choosing the right machine is a critical decision that can affect the efficiency, output, and quality of your products. This