Entering the confectionery business is a venture as sweet as the treats you’ll produce. At the heart of your operation, the jelly candy making machine is the key to creating those delightful chewy candies that consumers love.

Choosing the right machine is a critical decision that can affect the efficiency, output, and quality of your products. This extensive guide will walk you through the factors to consider when selecting the perfect jelly candy making machine for your business.

1. Business Size and Scale

Understanding the size and scale of your business is the first step. Are you a start-up looking to craft small batches, or an established enterprise aiming for mass production? Your production volume needs will significantly influence the machine’s capacity and capabilities.

2. Production Volume

Consider the amount of jelly candy you plan to produce daily, weekly, or during peak seasons. Machines vary in output, from small, manual devices to large, automated lines that can churn out thousands of pieces per hour.

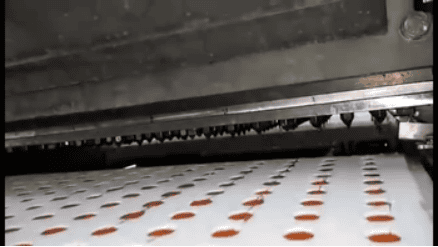

3. Type of Jelly Candies

Different machines may specialize in specific types of jelly candies, such as gummy bears, fruit slices, or jelly beans. Determine the variety you want to produce and look for machines that cater to those specific products.

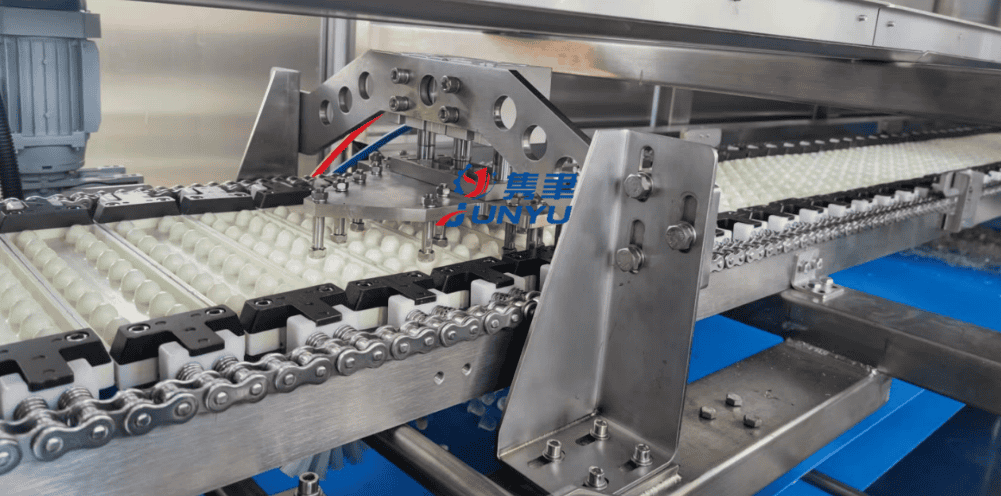

4. Automation Level

Automation can greatly affect the efficiency and cost-effectiveness of your operation. Decide how much of the process you want to automate, from simple machines that require manual loading and unloading to fully automated lines with robotic systems.

5. Machine Size and Footprint

The physical size of the machine and the space it requires will be crucial, especially if you have limited factory space. Ensure the machine fits within your facility and allows for adequate workflow and maintenance access.

6. Cost of the Machine

Machines can vary widely in price, from affordable, entry-level models to high-end, industrial-grade equipment. Set a budget that considers not only the initial cost but also operating expenses, maintenance, and potential upgrades.

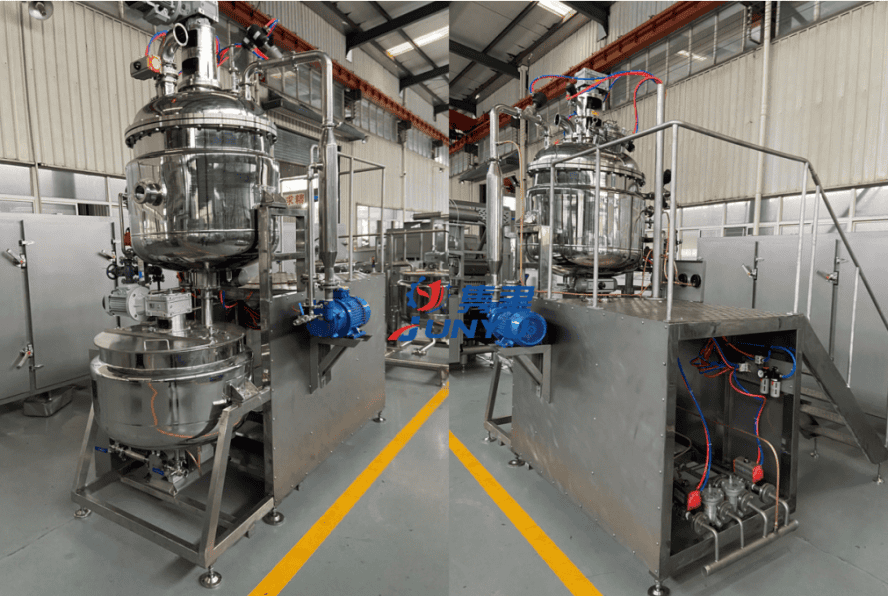

7. Quality and Consistency

The quality of the jelly candies is paramount. Look for machines that offer precise control over temperature, mixing, and molding to ensure consistent texture and flavor in every batch.

8. Ease of Operation

Consider the ease of use of the machine. Some machines are designed for simplicity and ease of operation, while others offer more complex controls for experienced operators.

9. Cleaning and Maintenance

Regular cleaning and maintenance are essential for food safety and machine longevity. Choose a machine that is easy to clean and maintain, with accessible parts and clear maintenance guidelines.

10. Safety Features

Ensure the machine complies with safety standards and includes features such as emergency stop buttons, safety guards, and interlocking mechanisms to prevent accidents.

11. Energy Efficiency

Energy-efficient machines can reduce operating costs and are better for the environment. Look for machines with energy-saving technologies and certifications.

12. Compliance with Regulations

Make sure the machine meets all local and international food safety regulations, including those related to materials, construction, and hygiene.

13. Warranty and After-Sales Service

A good warranty and reliable after-sales service are essential. This includes access to spare parts, technical support, and maintenance services.

14. Training and Support

Consider whether the machine supplier offers training and support to help you get started and troubleshoot any issues that may arise.

15. Customization and Scalability

As your business grows, you may need a machine that can be customized or scaled up. Check if the machine can be adapted to changing production needs.

16. Innovation and Technology

The confectionery industry is always evolving. Choose a machine that incorporates the latest technology and has the potential for innovation, such as 3D jelly printing or energy-saving systems.

17. Reviews and References

Look for reviews from other businesses in the confectionery industry and ask for references. Hearing about other users’ experiences can provide valuable insights.

18. Trial Runs and Demonstrations

If possible, visit the manufacturer for a demonstration or request a trial run of your product on the machine to see if it meets your quality and output expectations.

19. Financing Options

Consider the financing options available for purchasing the machine. Some manufacturers or third-party financiers may offer leasing or payment plans.

20. Long-Term Partnership

Choose a machine from a manufacturer with whom you can build a long-term relationship, ensuring ongoing support and access to future innovations.

Conclusion

Selecting the right jelly candy making machine is a decision that requires careful consideration of your business needs, production goals, and budget constraints. By taking a comprehensive approach to evaluating different machines, you can find the one that will become the heart of your confectionery operation, ensuring the production of high-quality jelly candies that delight your customers and contribute to the success of your business.