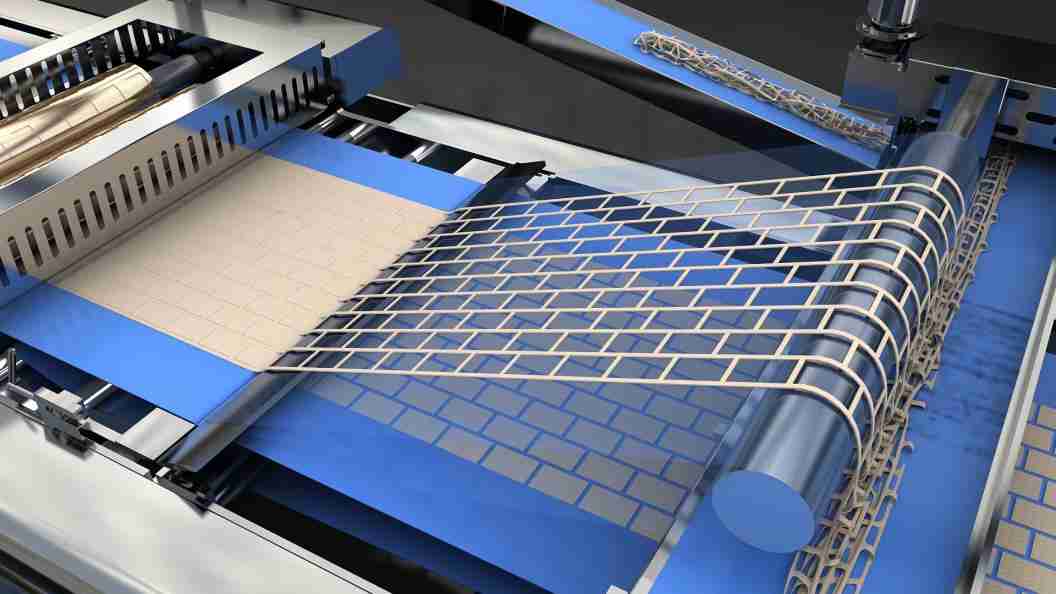

Marie biscuit is what we usually call hard dough-made biscuits, in which most of the hard dough needs to be fermented so Junyu advice laminating and 3-4sets of roller sheeting and roller cutting machine to make the topical hard dough products with a crispy taste, smooth surface, and layered cross-section. such as Marie,crackers, finger biscuits and soda biscuits..Machine Principle: After passing through the laminating machine(optional), three-roller feeder, and three pairs of roller flatting machines, the dough is cut into different shapes by the mold roller. The left dough passes through the dough separator and returns to the first feeder.The raw biscuit goes to the next equipment for baking.

| Model | JYB-280 | JYB-400 | JYB-600 | JYB-800 | JYB-1000 | JYB-1200 | JYB-1500 | Remark |

| Production capacity(kg/h) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | Customized capacity |

| Oven Length(m) | 16 | 28 | 40 | 40 | 60 | 50 | 70 | Depend |

| Total length(m) | 29.6 | 64.5 | 85.5 | 92.5 | 125 | 125 | 150 | If No U Turn Conveyor |

| Baking temperature(C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ | 190-240℃ | 190-240℃ | 190-240C | Depend |

| Whole line power(kW) | 80 | 90 | 300 | 400 | 00 | 800 | 900 | If Use Electric Oven |

| LPG Oven(kg/h) | 10 | 20 | 35 | 45 | 60 | 70 | 80 | If Use LPG Oven |

| Whole line weight(kg) | 6000 | 12000 | 20000 | 28000 | 35000 | 45000 | 55000 | Approx |

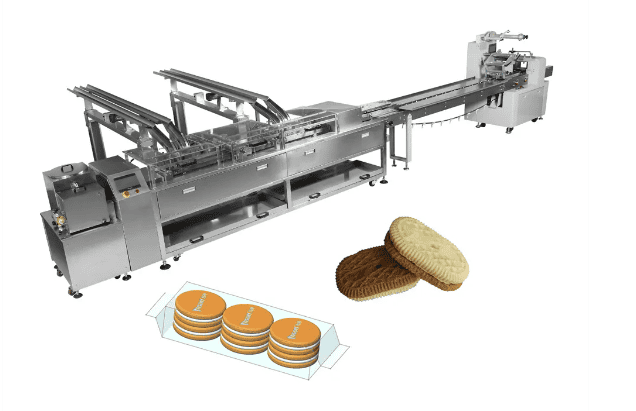

The fully automatic Mary’s biscuit production line is suitable for a wide range of biscuit production scenarios. It can be used to produce various types of biscuits, from traditional Mary’s biscuits to more specialized and innovative products. Whether for large – scale manufacturing facilities or smaller – scale production units, this line offers a versatile and efficient solution to meet diverse production needs.

In summary, the fully automatic Mary’s biscuit production line is an excellent choice for businesses in the food manufacturing industry. With its high – precision control, versatile production capabilities, energy – efficient operation, user – friendly interface, superior hygiene standards, customizable output, and cost – effective design, it provides an efficient and reliable solution for high – quality biscuit production.

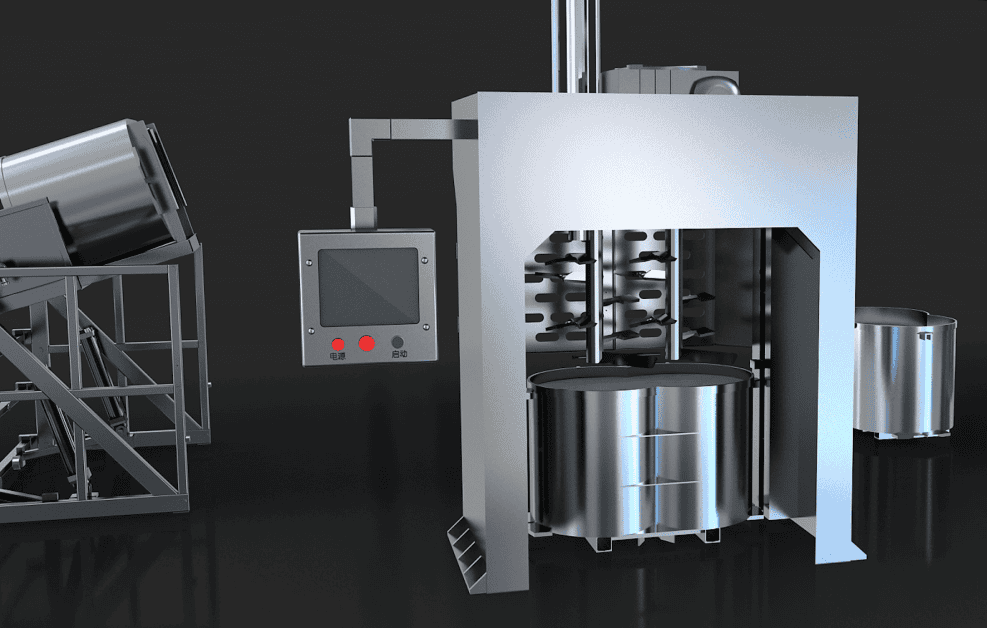

The process begins with a high – efficiency dough mixer. It evenly blends flour, sugar, fats, and other ingredients to form a consistent dough, laying the foundation for high – quality biscuits.

The dough is then passed through a dough sheeter, which rolls it into thin sheets of uniform thickness. This ensures that each biscuit will have a consistent texture and shape.

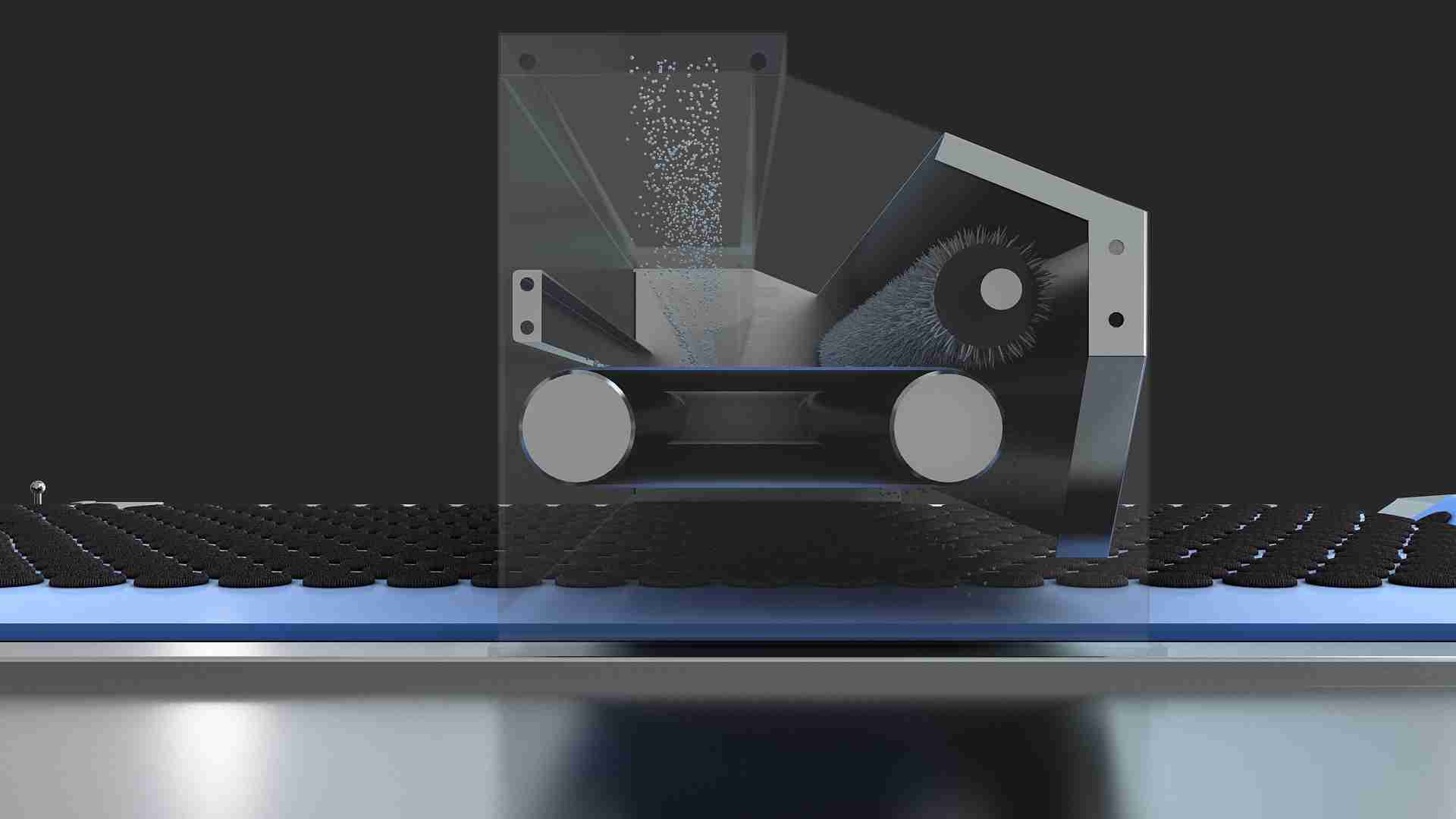

The rotary cutter trims the dough into the desired shapes. With adjustable cutting parameters, it ensures clean edges and minimal dough waste.

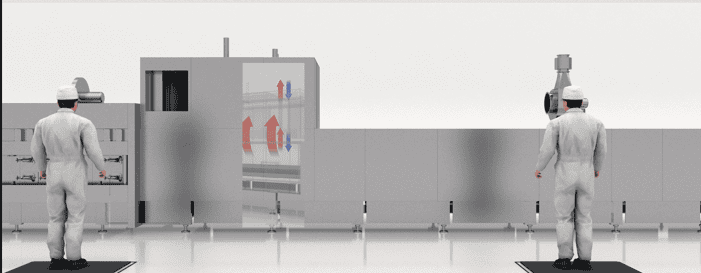

The formed dough pieces enter a tunnel oven for baking. The oven offers versatile heating options, including electricity and natural gas, and features precise temperature control to ensure even baking.

A salt and sugar sprinkle machine evenly applies salt and sugar to the dough pieces, enhancing flavor and adding a finishing touch before baking.

After cooling, the biscuits are efficiently stacked by a dedicated machine, preparing them for the packaging process.

For cream – filled Mary’s biscuits, a cream sandwiching machine fills cream between two layers of biscuits, creating delicious sandwich biscuits with precise cream application.

Finally, the biscuits are packaged using an automated packing system. This ensures they are neatly sealed and protected for distribution and sale.

Equipped with a PLC control system and touch screen interface, the production line allows for precise control over each step of the process. Parameters such as temperature, time, and depositing speed can be easily adjusted to meet specific production requirements.

The line can produce a wide variety of biscuits, including韧性 and酥性 biscuits. By simply changing molds and adjusting production formulas, it can create various shapes and flavors of biscuits to meet market demands.

Designed with energy efficiency in mind, the production line helps reduce operational costs. The tunnel oven, in particular, is available in electricity – and gas – heated models, offering flexibility and cost – effectiveness.

The production line features an intuitive control system that is easy to operate. With clear instructions and automated processes, operators can quickly become proficient in its use.

Constructed from high – quality stainless steel, the equipment meets food hygiene standards. Its design facilitates easy cleaning and maintenance, ensuring the safety and quality of the biscuits.

Available in various models with different production capacities, the line can be tailored to the specific needs of businesses of all sizes.

While the initial investment may seem significant, the line’s long – term operational efficiency and low maintenance costs make it a cost – effective choice for biscuit production.