Dernière mise à jour le 14 juin 2024 par jymachinetech

Hello, gummy gurus and confectionery connoisseurs!

Are you curious about the sweet science behind gummy manufacturing machines and how they transform the efficiency of your production line? If you’ve ever wondered how these marvelous machines can churn out gummy bears faster than you can say “gummi,” then you’re in for a treat.

Let’s dive into the chewy world of gummy production and explore how these machines make your operation not just efficient, but super-efficient.

1. Precision at Scale: Consistency in Every Batch

One of the most significant contributions of a machine de fabrication de gommes to production efficiency is its ability to produce gummies with remarkable consistency at scale.

These machines can mix, heat, and pour the gummy mixture with precision, ensuring that every batch is uniform in flavor, color, and texture. No more guesswork – just perfect gummies, every time.

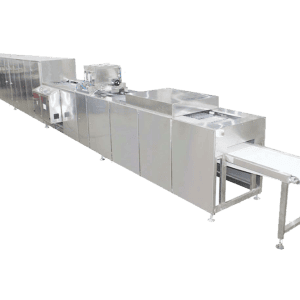

2. Automation: The Robotic Candy Maker

Ever dreamt of having a robot candy maker to do the heavy lifting? Gummy manufacturing machines bring that dream to life with automation features that reduce the need for manual labor. From ingredient mixing to mold filling, these machines take care of the entire process, allowing your team to focus on other aspects of production or enjoy a well-deserved break.

3. Speedy Production: Faster Than a Gummy Bear Race

The speed at which gummy manufacturing machines operate is truly impressive. They can produce gummies at a rapid pace, keeping up with high demand and increasing overall output. Imagine a gummy bear race, but instead of cute little bears, it’s a stampede of gummies pouring out of the machine – that’s the kind of speed we’re talking about.

4. Reduced Human Error: No More Misstepped Gummy Steps

By minimizing human intervention, gummy manufacturing machines significantly reduce the potential for human error. No more unevenly mixed batches or miscalculated ingredient ratios – these machines deliver accuracy down to the last drop, ensuring that your gummies are always up to par.

5. Energy Efficiency: Saving on the Power Bill

Modern gummy manufacturing machines are designed with energy efficiency in mind. They use less power to perform the same tasks as older, less advanced models. This not only benefits the environment but also helps you save on your energy bill, making your gummy production both green and economically friendly.

6. Customization and Flexibility: The Chameleon of Machines

Gummy manufacturing machines are not one-trick ponies. They offer a range of customization options, allowing you to produce various gummy shapes, sizes, and flavors. This flexibility means you can cater to diverse market demands without having to invest in multiple machines or change your production line frequently.

7. Continuous Operation: The Non-Stop Gummy Factory

Some gummy manufacturing machines are built for continuous operation, which means they can run around the clock without stopping. This non-stop production capability is a game-changer for meeting tight deadlines or high-volume orders, ensuring that your gummy supply is always ready to bounce back onto the shelves.

8. Easy Cleaning and Maintenance: A Well-Oiled Candy Machine

Machines de fabrication de gommes are designed with ease of cleaning and maintenance in mind. They often feature detachable parts and automated cleaning systems that make the post-production cleanup a breeze. A clean machine is a happy machine, and a well-maintained machine ensures that your gummies keep coming out just right.

9. Quality Control Integration: The Gummy Inspector

Many gummy manufacturing machines come with integrated quality control systems that monitor the production process in real-time. These systems can detect inconsistencies in size, shape, or color and make adjustments on the fly. It’s like having a team of gummy inspectors working around the clock to ensure quality.

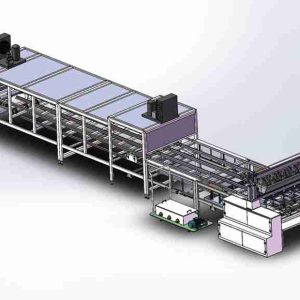

10. Space Efficiency: Small Footprint, Big Output

Machines de fabrication de gommes are designed to maximize output while minimizing the space they occupy. This space efficiency is particularly beneficial for businesses with limited production facilities, allowing them to produce large quantities of gummies without taking up a lot of room.

11. Reduced Waste: The Eco-Friendly Gummy Producer

By accurately controlling ingredient ratios and production processes, gummy manufacturing machines help reduce waste. This not only benefits the environment but also contributes to cost savings by minimizing the amount of raw materials used.

12. Advanced Technology: The Gummy Machine 2.0

With advancements in technology, gummy manufacturing machines are becoming smarter and more connected. They can be integrated with enterprise resource planning (ERP) systems, allowing for better inventory management, production tracking, and data analysis.

13. Operator Safety: A Safe and Sound Gummy Environment

Safety features in gummy manufacturing machines contribute to a secure working environment. They include emergency stop buttons, enclosed guarding, and interlocking systems that prevent accidents and ensure that your team can work safely while producing those chewy delights.

14. Scalability: Growing with Your Business

As your business grows, so can your gummy production capabilities. Machines de fabrication de gommes can often be scaled up or networked with additional machines to increase production capacity without compromising on efficiency.

15. Innovation and Adaptability: Keeping Up with the Gummy Times

The confectionery industry is always evolving, and gummy manufacturing machines are no exception. They are designed to adapt to new techniques, recipes, and market trends, ensuring that your production line stays current and competitive.

Conclusion

Machines de fabrication de gommes are the unsung heroes of the confectionery world, working tirelessly to ensure that your gummy production line is as efficient as can be. From precision and automation to energy efficiency and customization, these machines are the secret ingredient in your gummy-making success. So, the next time you pop a gummy bear into your mouth, remember the hard work and efficiency of the machine that made it all possible. Happy gummy producing!

Souviens-toi: A gummy manufacturing machine is more than just a piece of equipment; it’s your ticket to a sweet, efficient, and successful confectionery business. By leveraging the capabilities of these machines, you’re setting yourself up for a world of chewy possibilities. Keep those gummies coming!

Pourquoi nous choisir?

Shanghai Junyu a débuté en tant que fabricant d'équipements alimentaires spécialisé dans divers types de machines pour l'industrie alimentaire. Notre gamme comprend des machines de fabrication de biscuits, des machines de fabrication de bonbons, des machines de fabrication de chocolat, des machines de fabrication de gaufrettes, des machines de fabrication de gâteaux, des machines d'emballage, etc. Avec un engagement envers la qualité et l’innovation, nous nous efforçons de fournir des équipements de premier ordre pour répondre aux divers besoins de nos clients du secteur de la fabrication alimentaire.

Gamme de produits diversifiée: Junyu propose une large gamme d'équipements alimentaires, notamment des machines à fabriquer des biscuits, des machines à fabriquer des bonbons, des machines à fabriquer du chocolat, etc., répondant aux divers besoins de l'industrie alimentaire.

Machines de haute qualité: Junyu s'engage à produire des équipements de haute qualité, garantissant durabilité, fiabilité et efficacité dans les processus de production alimentaire.

Technologie innovante: En mettant l'accent sur l'innovation, Junyu intègre une technologie de pointe dans ses machines, améliorant ainsi les performances et la productivité de ses clients.

Options de personnalisation: Junyu propose des options de personnalisation pour adapter les machines en fonction des exigences spécifiques du client, garantissant que chaque machine répond aux besoins uniques de ses utilisateurs.

Expertise et expérience: Avec des années d'expérience dans l'industrie, Junyu a développé une expertise dans la fabrication d'équipements alimentaires, offrant à ses clients des produits fiables soutenus par une connaissance de l'industrie.

Portée mondiale: Junyu a une présence mondiale, au service de clients du monde entier et fournissant une assistance et des services partout où cela est nécessaire.