The allure of jelly candies lies in their chewy texture and vibrant flavors, making them a popular choice in confectionery markets worldwide. The production of these delightful treats is facilitated by jelly candy making machines, which vary significantly in capacity and complexity.

This in-depth article explores the capacity of a typical jelly candy making machine, delving into the factors that influence production capabilities and how manufacturers can optimize output.

1. Definition of Capacity

Capacity, in the context of jelly candy making machines, refers to the number of units the machine can produce within a given time frame, typically measured in units per hour or per day. The capacity is influenced by several factors, including machine size, design, automation level, and the specific candy recipe.

2. Small-Scale Machines

Small-scale jelly candy making machines are designed for low to medium production volumes, suitable for artisanal producers, small businesses, or startups. These machines may produce anywhere from a few hundred to a few thousand units per hour, depending on their design and efficiency.

3. Medium-Scale Machines

Medium-scale machines are engineered to meet the needs of moderate production demands. They offer higher production capacities than small-scale machines, typically ranging from several thousand to tens of thousands of units per hour. These machines are ideal for established businesses looking to increase their output without investing in large industrial equipment.

4. Large-Scale Industrial Machines

Large-scale industrial jelly candy making machines are the workhorses of the confectionery industry, capable of producing hundreds of thousands to millions of units per hour. These machines are highly automated, with multiple integrated systems working in tandem to ensure efficient, high-volume production.

5. Factors Influencing Capacity

Several factors influence the capacity of a jelly candy making machine, including:

- Machine Size: Larger machines generally have a higher production capacity.

- Automation Level: Higher levels of automation can lead to increased efficiency and output.

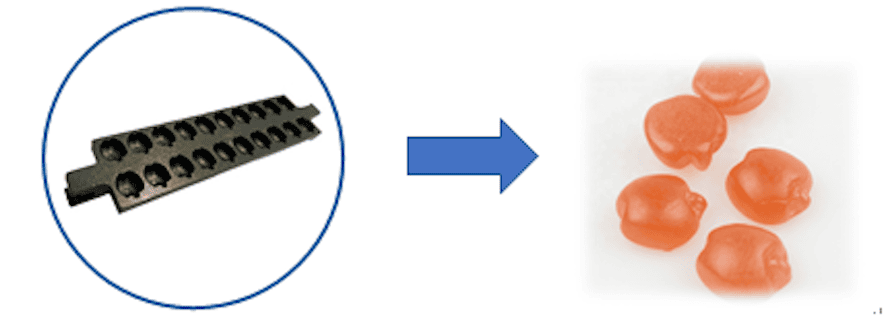

- Mold Design: The number and arrangement of molds in the machine affect how many candies can be produced simultaneously.

- Candy Size and Complexity: Larger or more complex candies may require more time to produce, affecting overall capacity.

- Operator Skill: The skill and efficiency of machine operators can significantly impact production output.

- Maintenance and Machine Condition: Well-maintained machines are more likely to run at peak efficiency.

6. Batch Production

Some jelly candy making machines operate on a batch basis, where ingredients are mixed, cooked, and deposited into molds in discrete cycles. The capacity of these machines is determined by the size of the batch and the time required to complete each cycle.

7. Continuous Production

In contrast, continuous production machines are designed to operate without interruption, allowing for a steady stream of jelly candies to be produced. These machines often have a higher capacity than batch production machines.

8. Customization and Scalability

Manufacturers may offer customization options for jelly candy making machines, allowing buyers to specify features that can impact capacity, such as additional molds or faster depositing systems. Scalability is also a consideration, with some machines designed to be easily upgraded or expanded to increase capacity as production needs grow.

9. Energy Efficiency

The capacity of a jelly candy making machine can also be influenced by its energy efficiency. Machines that consume less energy per unit of output can potentially run for longer periods without downtime, thereby increasing overall capacity.

10. Quality Assurance

While capacity is important, it should not come at the expense of quality. Jelly candy making machines must maintain consistent product quality even at higher production volumes, which may require additional features such as automated quality control systems.

11. Market Demand

Understanding market demand is crucial when considering the capacity of a jelly candy making machine. Manufacturers must ensure that their chosen machine can meet the anticipated demand for their products while providing room for growth.

12. Cost Implications

The capacity of a jelly candy making machine often correlates with its cost. Higher-capacity machines typically require a larger initial investment but may offer better returns on investment due to increased production efficiency.

13. Regulatory Considerations

Regulatory requirements can also impact the capacity of a jelly candy making machine. Compliance with food safety standards may necessitate specific features or processes that could affect production speed or output.

14. After-Sales Support

When evaluating the capacity of a jelly candy making machine, consider the after-sales support provided by the manufacturer. This includes training, maintenance, and potential upgrades to increase capacity in the future.

15. Future Trends and Innovations

The confectionery industry is continually evolving, with new technologies and innovations that can impact the capacity of jelly candy making machines. Keeping abreast of these trends can help manufacturers make informed decisions about their production capabilities.

Conclusion

The capacity of a typical jelly candy making machine is a multifaceted concept that encompasses more than just the number of candies produced in a given time. It involves a careful balance of machine size, automation, efficiency, quality, and cost, all within the context of market demand and regulatory requirements. By understanding these factors, manufacturers can select or customize a jelly candy making machine that meets their specific production needs while providing the flexibility to adapt to future challenges and opportunities.