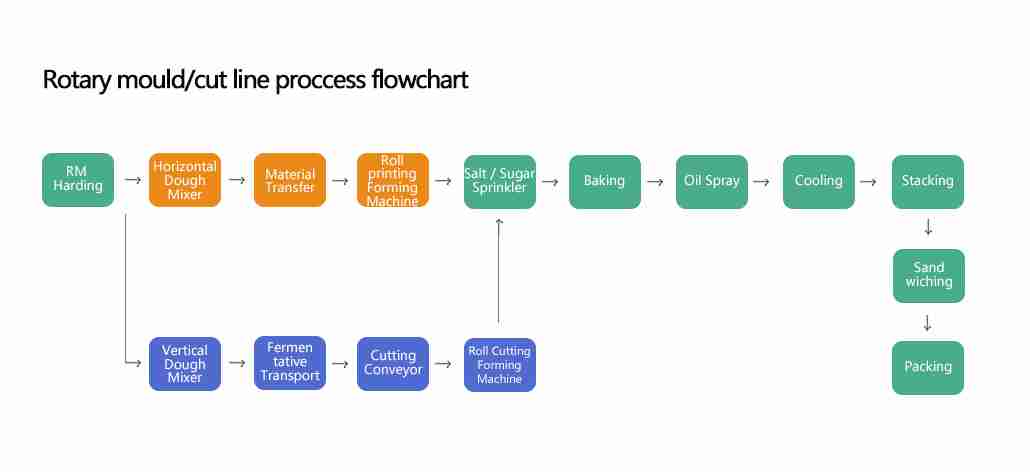

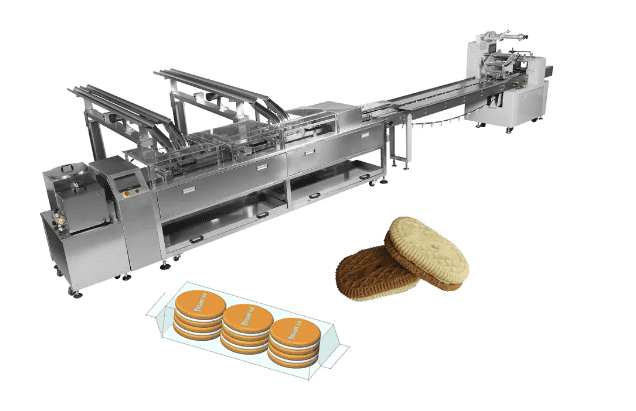

A capacidade de produção varia de acordo com os modelos: as linhas pequenas totalmente automáticas podem produzir de 100 a 800 kg/h, enquanto as grandes podem produzir de 800 a 1500 kg/h. O layout pode ser ajustado com base no espaço disponível, com seções de giro adicionadas conforme necessário.

O equipamento apresenta um design novo e compacto com alta automação. Ele automatiza totalmente o processo, desde a alimentação até a laminação, a modelagem, a reciclagem de resíduos, a secagem, a pulverização de óleo e o resfriamento.

Ela pode produzir vários tipos de biscoitos, incluindo os macios e os duros. Mudando os moldes e ajustando as receitas, ele pode criar biscoitos premium populares, como biscoitos de creme, sanduíche, refrigerante, em formato de animal e vegetais.

A Jy Company oferece uma ampla variedade de moldes e fórmulas de processamento para os clientes.

| Modelo(pequeno e médio) | JYB-280 | JYB-400 | JYB-600 | JYB-800 |

| Capacidade de produção (kg/h) | 100 | 250 | 500 | 750 |

| Comprimento do forno (m) | 16 | 28 | 40 | 40 |

| Espaço necessário na fábrica (m) | 5×25 | 10×40 | 15×50 | 15×50 |

| Temperatura de cozimento (C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ |

| Potência da linha inteira (kW) | 80 | 90 | 300 | 400 |

| Forno a GLP (kg/h) | 10 | 20 | 35 | 45 |

| Peso da linha inteira (kg) | 6000 | 12000 | 20000 | 28000 |

Capacidade :

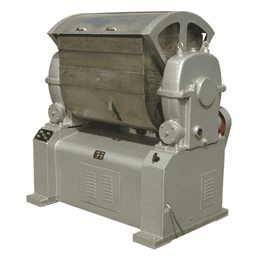

Misturador de farinha:

O misturador de farinha é usado para misturar farinha com outros ingredientes secos, como açúcar e fermento em pó, criando uma mistura seca homogênea que serve como base para a produção de biscoitos.

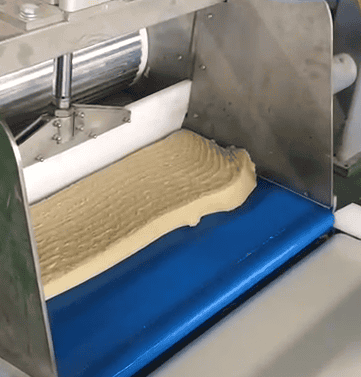

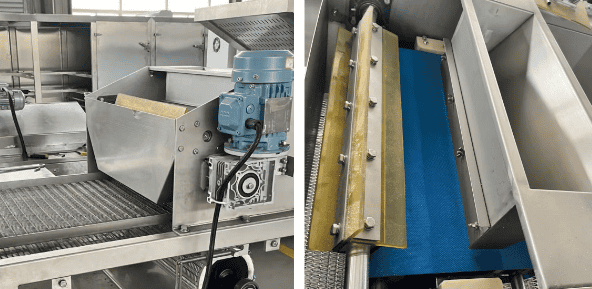

Corte e transporte de massa:

Esse componente corta a massa em pedaços uniformes e os transporta para o próximo estágio da produção, garantindo um dimensionamento consistente e um fluxo de trabalho eficiente.

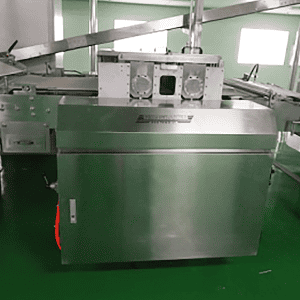

Moldador rotativo (biscoito macio):

O moldador rotativo molda a massa de biscoitos macios nas formas desejadas usando moldes rotativos, ideais para produzir biscoitos de textura macia com formato e tamanho uniformes.

Cortador rotativo (biscoito de massa dura):

Projetado para biscoitos de massa dura, esse equipamento corta a massa em formas precisas e uniformes, garantindo bordas limpas e qualidade consistente do produto.

Sal e açúcar polvilhados:

Essa máquina distribui uniformemente o sal e o açúcar nos pedaços de massa, realçando o sabor e dando um toque final antes de assar.

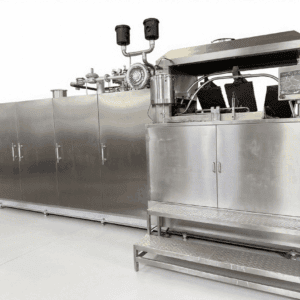

Forno de túnel:

O forno túnel, equipado com eletricidade, GLP ou diesel, assa os biscoitos à medida que eles passam por uma esteira transportadora, garantindo um cozimento uniforme e uma produção eficiente.

Curva em U de 180o:

O mecanismo de giro de 180/90 graus permite o rearranjo eficiente dos biscoitos na esteira transportadora, facilitando as transições suaves entre os diferentes estágios de produção.

Empilhamento de biscoitos:

Esse equipamento empilha biscoitos assados de forma eficiente, preparando-os para processos subsequentes, como embalagem ou processamento adicional.

Máquina de sanduíche de biscoito de creme:

Ele preenche o creme entre duas camadas de biscoitos, criando biscoitos tipo sanduíche com aplicação precisa do creme e garantindo um produto delicioso e uniformemente recheado.

Perguntas e respostas

Shortcake é um tipo de biscoito com uma textura quebradiça, enquanto o biscoito duro tem uma textura mais dura e é mais resistente à mastigação. O shortcake geralmente tem um teor mais alto de gordura e açúcar, o que lhe confere uma estrutura mais quebradiça. O biscoito duro, por outro lado, tem um teor menor de gordura e açúcar, resultando em uma textura mais firme. A superfície do shortcake geralmente tem um padrão em relevo, enquanto o biscoito duro geralmente tem um buraco redondo côncavo e uma aparência mais lisa.

Um cookie é uma massa pequena, plana e assada, geralmente doce, que pode ser feita com vários ingredientes, como farinha, açúcar e manteiga. Os cookies podem ter diferentes texturas e sabores, variando de macios e mastigáveis a crocantes e amanteigados.

Os biscoitos podem ser amplamente classificados em vários tipos, incluindo biscoito duro, biscoito macio, biscoito de soda e wafers. O biscoito macio tem uma textura mais dura e é mais resistente à mastigação, o biscoito macio tem uma textura quebradiça, os biscoitos de soda são feitos de massa fermentada e têm um sabor fermentado característico, e os wafers são leves e porosos com menos açúcar e gordura.

Fornos de rack rotativo: Projetado para operações de cozimento de alto volume com um sistema de prateleiras rotativas para garantir um cozimento uniforme.

Fornos de túnel: Fornos especializados para produção contínua e de alto volume. Os produtos passam pelo forno em uma esteira transportadora.

Os fornos elétricos de túnel usam o efeito Joule para gerar calor. Eles são simples de operar e manter, e podem aquecer zonas separadas a diferentes temperaturas. São altamente eficientes, sem emissões, e oferecem controle preciso da temperatura.

A tecnologia de infravermelho pode ser usada em fornos e pode ser alimentada por gás ou eletricidade. Ela transfere energia térmica na forma de ondas eletromagnéticas e é eficaz para dourar superfícies, secar, curar e derreter coberturas de produtos

O gás natural é uma das fontes de energia mais comuns para fornos de túnel. Ele oferece bom controle de temperatura, flexibilidade e é limpo e higiênico na operação.

O GLP é portátil e versátil, o que o torna adequado para áreas sem infraestrutura de gás natural. Ele tem uma densidade de energia maior do que o gás natural e oferece benefícios semelhantes em termos de controle de temperatura e flexibilidade

O custo inicial dos fornos a gás pode ser mais alto do que o dos fornos elétricos, mas eles oferecem baixos custos operacionais e aquecimento rápido

O diesel é menos comum, mas pode ser usado em áreas onde não há disponibilidade de gás natural ou GLP.

O óleo combustível às vezes é usado em áreas onde não há disponibilidade de gás natural ou GLP. Ele é relativamente barato, mas produz emissões mais altas em comparação com o gás natural ou o GLP

Os fornos de túnel híbridos combinam diferentes tecnologias de aquecimento, como convecção direta e convecção indireta, oferecendo os benefícios de vários métodos de aquecimento em uma única máquina. Isso permite maior flexibilidade e melhor qualidade do produto

| Modelo(pequeno e médio) | JYB-280 | JYB-400 | JYB-600 | JYB-800 |

| Capacidade de produção (kg/h) | 100 | 250 | 500 | 50 |

| Comprimento do forno (m) | 16 | 28 | 40 | 40 |

| Espaço necessário na fábrica (m) | 5×25 | 10×40 | 15×50 | 15×50 |

A Junyu tem mais capacidade e máquinas maiores para escolher.