Última atualização em 1 de junho de 2024 por jymachinetech

The packaging of ursinhos de goma is the final step in the production process, ensuring that these chewy delights are not only protected and preserved but also presented in a way that appeals to consumers.

This article will explore the various methods and machinery used by máquinas de ursinhos de goma to package the finished gummies for distribution.

1. Cooling and Solidification

Before packaging, the gummy bears must be fully cooled and solidified. This ensures they hold their shape and are firm enough to be handled by the packaging machinery.

2. Demolding

Once set, the gummy bears are carefully removed from their molds. The demolding process must be precise to avoid damaging the gummies, which can affect their appearance and quality.

3. Quality Inspection

After demolding, each gummy bear undergoes a quality inspection to ensure they meet the required standards. This includes checking for the correct shape, size, and absence of defects.

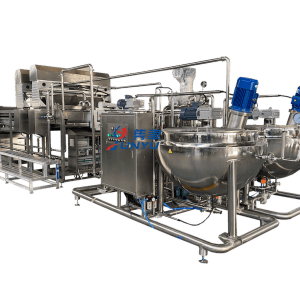

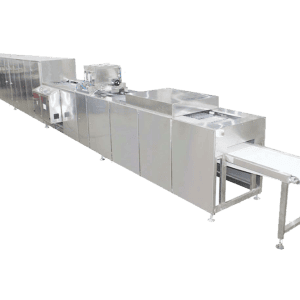

4. Automated Packaging Lines

Máquinas de ursinhos de goma are often connected to automated packaging lines. These lines are designed to streamline the process of packaging the gummies, from placing them in wrappers to sealing and labeling.

5. Counting and Collating

Machines with counting and collating mechanisms accurately count the ursinhos de goma and arrange them in the desired formation for packaging. This could be in rows for a bag, in a specific pattern for a box, or in bulk for a larger container.

6. Wrapping

The gummy bears are then wrapped in a protective film or paper to prevent them from sticking together and to maintain their freshness. This wrapping can also include printed material with nutritional facts and other information.

7. Sealing

After wrapping, the packages are sealed to ensure they are airtight and secure. Heat sealing is a common method used in packaging gummy bears, providing a strong and tamper-evident closure.

8. Labeling and Coding

Machines apply labels to the packages, which may include branding, nutritional information, barcodes, and expiration dates. Coding machines can also print batch codes or expiration dates directly onto the packaging.

9. Case Packing

Individual packages of gummy bears are then grouped into cases or boxes for bulk distribution. Case packing machines handle this task, stacking the packages neatly and securely.

10. Shrink Wrapping

Some packaging lines use shrink wrapping to encase the grouped packages in a plastic film. This provides an additional layer of protection and a professional finish.

11. Palletizing

The cases or boxes are then placed onto pallets for transportation. Palletizing machines lift and stack the cases onto pallets, which are then wrapped with stretch film for stability during transit.

12. Quality Control Checks

Throughout the packaging process, quality control checks are performed to ensure that the packaging is secure, the labels are correctly applied, and the gummy bears are free from damage.

13. Automation and Robotics

Modern gummy bear packaging machines often incorporate automation and robotics to improve efficiency and accuracy. These technologies can handle complex packaging tasks with minimal human intervention.

14. Custom Packaging Solutions

Depending on the brand and product, gummy bear machines may be adapted to accommodate custom packaging solutions. This could include unique wrappers, specialty boxes, or innovative packaging designs.

Conclusão

The packaging of gummy bears is a critical step that protects the product, extends its shelf life, and enhances its appeal to consumers. With advanced machinery and automation, gummy bear manufacturers can ensure that their products are packaged efficiently, reliably, and with an eye for detail that reflects the care taken in their production. The result is a product that is ready for distribution and designed to delight gummy bear fans everywhere.

Porque escolher-nos?

A Shanghai Junyu começou como fabricante de equipamentos alimentícios, especializada em diversos tipos de máquinas para a indústria alimentícia. Nossa linha inclui máquinas para fazer biscoitos, máquinas para fazer doces, máquinas para fazer chocolate, máquinas para fazer wafers, máquinas para fazer bolos, máquinas de embalagem e muito mais. Com o compromisso com a qualidade e a inovação, nos esforçamos para fornecer equipamentos de primeira linha para atender às diversas necessidades de nossos clientes no setor de fabricação de alimentos.

Gama diversificada de produtos: A Junyu oferece uma ampla variedade de equipamentos para alimentos, incluindo máquinas para fazer biscoitos, máquinas para fazer doces, máquinas para fazer chocolate e muito mais, atendendo a diversas necessidades da indústria alimentícia.

Máquinas de alta qualidade: A Junyu tem o compromisso de produzir equipamentos de alta qualidade, garantindo durabilidade, confiabilidade e eficiência nos processos de produção de alimentos.

Tecnologia inovadora: Com foco na inovação, a Junyu integra tecnologia avançada em suas máquinas, melhorando o desempenho e a produtividade de seus clientes.

Opções de personalização: A Junyu oferece opções de personalização para adequar as máquinas de acordo com as necessidades específicas do cliente, garantindo que cada máquina atenda às necessidades exclusivas de seus usuários.

Conhecimento e Experiência: Com anos de experiência na indústria, a Junyu desenvolveu experiência na fabricação de equipamentos para alimentos, oferecendo aos clientes produtos confiáveis apoiados pelo conhecimento da indústria.

Alcance global: A Junyu tem presença global, atendendo clientes em todo o mundo e fornecendo suporte e serviços sempre que necessário.