Gummy candies, including gummy bears, are known for their consistent flavor and vibrant colors throughout each piece. Achieving this uniformity is no accident; it’s the result of careful formulation and precise machinery operation.

This article explores how the manufacturing process and specialized equipment ensure that every gummy bear is packed with even flavor and color.

1. Ingredient Preparation

The first step in ensuring an even distribution of flavorings and colorings is meticulous ingredient preparation. Manufacturers begin by selecting high-quality natural or artificial flavors and food-grade colorings. These ingredients are then precisely measured to achieve the desired intensity and consistency across the entire batch.

2. High-Quality Mixing Equipment

The heart of even distribution lies in the mixing process, which is facilitated by high-quality industrial mixers. These machines are designed to provide thorough and uniform mixing. Planetary mixers, for example, rotate on their own axis while also revolving around the mixing bowl, ensuring that every ingredient is evenly dispersed.

3. Gelatin and Base Mixture

Gelatin serves as the base for gummy candies and plays a crucial role in the distribution of flavors and colors. When mixed with warm water, gelatin forms a matrix that can evenly suspend and distribute the added flavors and colorings. The base mixture is heated to a specific temperature to ensure complete dissolution and homogeneity.

4. Sequential Addition

To further ensure even distribution, manufacturers often add flavors and colorings in a controlled, sequential manner. By adding these ingredients in stages, the mixer can blend each component thoroughly before adding the next, reducing the risk of clumping or uneven distribution.

5. Continuous Mixing

Continuous mixing is a technique used to maintain the even distribution of ingredients throughout the entire production run. This method involves keeping the mixture in motion, with a steady flow of new ingredients being added and mixed in as the batch is being used to fill molds.

6. Temperature Control

Precise temperature control is vital for the even distribution of flavors and colorings. Different ingredients have different optimal temperatures for dissolution and stability. Industrial mixing equipment often includes heating or cooling jackets to maintain the mixture within a narrow temperature range.

7. Quality Checks

Throughout the mixing process, quality checks are performed to ensure that the distribution of flavors and colorings is consistent. This can involve visual inspections, as well as more technical tests such as color measurement devices that assess the uniformity and intensity of the coloring.

8. Filtration Systems

Some gummy candy production lines incorporate filtration systems to ensure that the mixture is free from lumps or clumps of undissolved ingredients. These systems help maintain a smooth, homogenous mixture that will produce uniformly flavored and colored gummies.

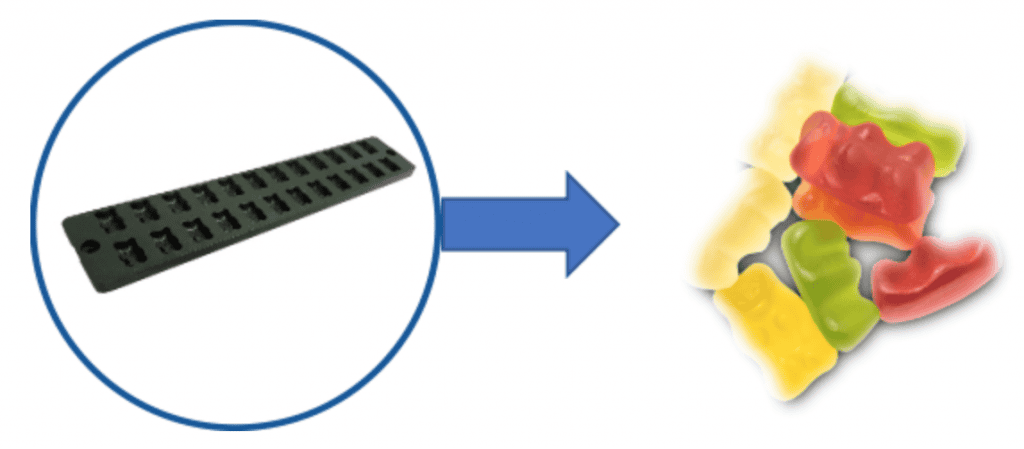

9. Mold Filling Techniques

The method of filling the molds also impacts the distribution of flavors and colorings. Machines that fill molds must do so evenly and consistently to avoid any concentration of ingredients in certain areas. This can involve pressure-controlled pumps or automated pouring systems.

10. Cooling and Setting

Once the molds are filled, the gummies are allowed to cool and set. This process is carefully controlled to ensure that the flavors and colorings remain evenly distributed as the gummies solidify.

Conclusion

The even distribution of flavorings and colorings in gummy candies is a result of a combination of careful ingredient selection, precise machinery operation, and stringent quality control processes. From the initial mixing stages to the final cooling and setting, each step is carefully orchestrated to deliver a consistent and enjoyable experience with every chewy bite. The uniformity we appreciate in gummy bears is a testament to the sophistication of candy-making technology and the expertise of confectioners.