The market for gummy bear machines is as diverse and colorful as the gummy bears they produce. These machines cater to a range of production needs, from small-scale, artisanal operations to large-scale industrial manufacturing.

This article will provide an overview of the different types of gummy bear machines available, highlighting their unique features and applications.

1. Batch Processing Machines

Batch processing machines are designed for moderate production volumes. They operate in batches, allowing for flexibility in production and the ability to make adjustments between batches. These machines are ideal for small to medium-sized businesses looking to produce gummy bears without a massive initial investment.

2. Continuous Flow Machines

Continuous flow machines are built for high-volume production. They operate continuously, with a steady flow of ingredients being mixed, cooked, and deposited into molds. These machines are commonly used in large-scale industrial settings where consistent output is required.

3. Tablet Press Machines

While not exclusively for gummy bears, tablet press machines can be used to produce gummy bear-like candies. These machines compress powdered ingredients into solid forms, suitable for creating gummy bears with a firm texture. They are often used for making gummies with added supplements or medications.

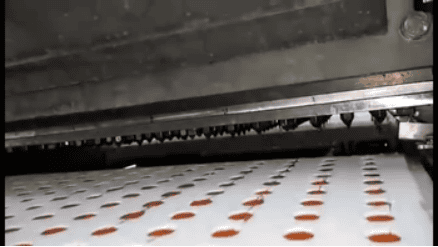

4. Depositing Machines

Depositing machines are used to fill molds with a precise amount of gummy mixture. They can be semi-automatic or fully automatic, with some models offering the ability to deposit multiple flavors or colors simultaneously. These machines are popular for their accuracy and efficiency.

5. Molding Machines

Molding machines specialize in the final stage of gummy bear production, where the gummy mass is cooled and set in molds. They can be simple manual presses or fully automated systems with integrated cooling tunnels and demolding mechanisms.

6. Encrusting Machines

Encrusting machines are used to apply a coating or filling to pre-formed gummy bears. This type of machine can add a layer of chocolate, sugar, or other toppings to enhance the flavor and texture of the gummies.

7. Custom-Shape Machines

Custom-shape machines are designed to produce gummy bears in unique and intricate shapes. These machines use complex molds and may offer additional features such as multi-color or multi-flavor capabilities.

8. Artisanal Machines

Artisanal machines cater to the needs of small-scale producers or home enthusiasts. They are typically smaller, less automated, and allow for greater control over the production process, enabling the creation of handcrafted gummy bears.

9. Automatic Packaging Machines

For the final step in production, automatic packaging machines can be integrated with gummy bear production lines. These machines wrap, seal, and package the gummy bears, ensuring they are ready for distribution.

10. Co-Extrusion Machines

Co-extrusion machines are capable of producing gummy bears with layered or filled centers. They work by extruding two or more different materials simultaneously, creating a product with a distinct inner and outer layer.

11. 3D Printing Machines

On the cutting edge of gummy bear production, 3D printing machines can create gummies in virtually any shape or design. These machines offer a high level of customization and are used for creating intricate and detailed gummy creations.

12. Energy-Efficient Machines

With a focus on sustainability, some manufacturers are developing energy-efficient gummy bear machines. These machines are designed to minimize power consumption and reduce the environmental impact of gummy bear production.

Conclusion

The variety of gummy bear machines available on the market reflects the diverse needs of candy makers around the world. Whether you’re a small artisan looking to craft unique gummy creations or a large manufacturer seeking high-volume production, there’s a gummy bear machine suited to your requirements. As technology advances, we can expect to see even more innovation in the types of machines available for producing these beloved chewy treats.