Highly Automated: Reduces manual labor and increases production efficiency.

Diverse Products: Can produce various shapes and flavors of teddy bear biscuits by changing molds and recipes.

Efficacité énergétique: Equipped with energy-saving technologies to reduce operational costs.

Conception hygiénique: Uses food – grade materials and easy – to – clean designs to meet food safety standards.

User – Friendly: Features an intuitive control system for easy operation and monitoring.

| Modèle | JYB-280 | JYB-400 | JYB-600 | JYB-800 | JYB-1000 | JYB-1200 | JYB-1500 | Remarque |

| Capacité de production (kg/h) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | Capacité personnalisée |

| Longueur du four (m) | 16 | 28 | 40 | 40 | 60 | 50 | 70 | Dépendance |

| Longueur totale (m) | 29.6 | 64.5 | 85.5 | 92.5 | 125 | 125 | 150 | Si aucun U Turn Conveyor |

| Température de cuisson (C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ | 190-240℃ | 190-240℃ | 190-240C | Dépendance |

| Puissance totale de la ligne (kW) | 80 | 90 | 300 | 400 | 00 | 800 | 900 | Si vous utilisez un four électrique |

| Four GPL (kg/h) | 10 | 20 | 35 | 45 | 60 | 70 | 80 | Si vous utilisez un four à GPL |

| Poids de la ligne entière (kg) | 6000 | 12000 | 20000 | 28000 | 35000 | 45000 | 55000 | Approximativement |

The process begins with a dough mixer, which efficiently blends flour, sugar, fats, and other ingredients to form a uniform dough. This step ensures the dough has the right consistency for shaping into teddy bear biscuits.

If the recipe requires it, the dough undergoes a fermentation process. This step is crucial for developing the dough’s texture and flavor, resulting in a more enjoyable eating experience.

A specialized printing machine is used to imprint various patterns onto the dough. This adds visual appeal and character to the teddy bear biscuits, making them more attractive to consumers.

The rotary cutter shapes the dough into the iconic teddy bear form. With precision and efficiency, this machine ensures each biscuit is uniformly shaped, providing a consistent product.

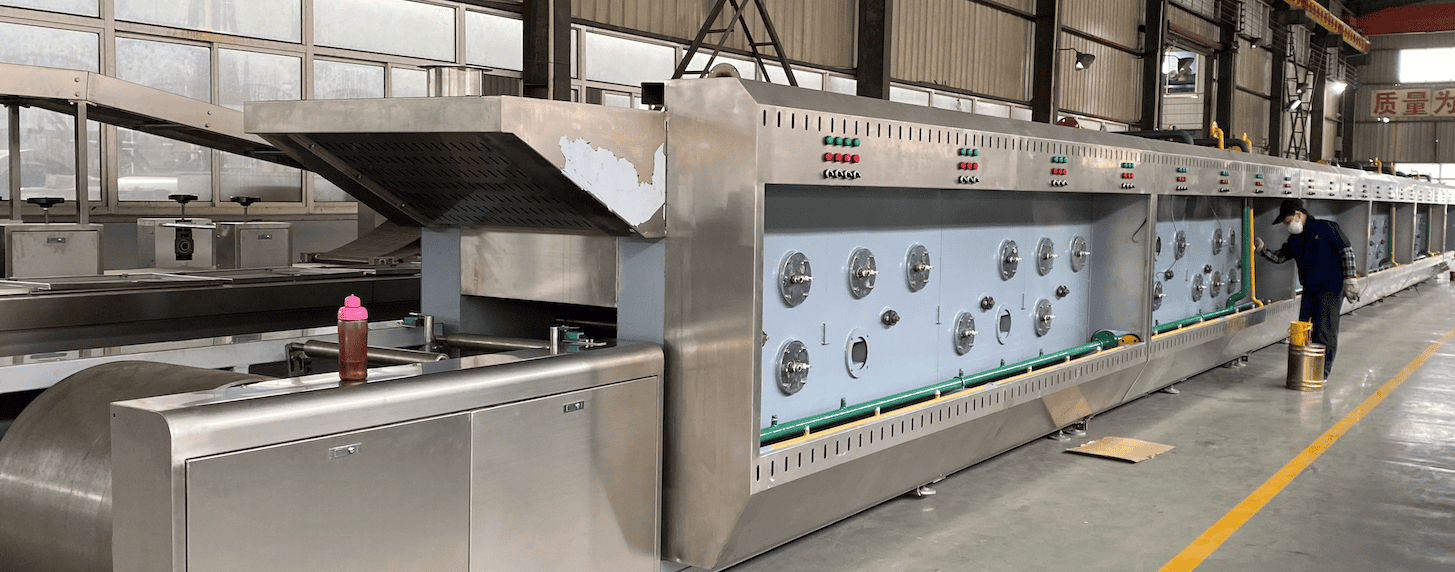

Teddy bear biscuits pass through a tunnel oven, which can be heated by electricity, gas, or other fuels. The oven’s precise temperature control ensures even baking, bringing out the golden color and delicious taste of the biscuits.

After baking, the biscuits move to the chocolate filling station. Here, a filling machine injects chocolate or other fillings into the biscuits, adding an extra layer of flavor and enjoyment.

Finally, the filled teddy bear biscuits are packaged using an automated packing system. This ensures they are neatly sealed and protected for distribution and sale.