Haut de page Machine à bonbons gommeux pour une production efficace et des résultats de qualité

Introduction à la production de chewing-gums

- Le processus de production des bonbons gélifiés consiste à créer une variété de bonbons gélifiés, notamment des oursons gélifiés, des vers et des fruits, à l'aide d'équipements de confiserie spécialisés. Au cours de la production, les fabricants peuvent ajouter différents ingrédients tels que des arômes, des colorants ou des composants fonctionnels pour créer des produits divers et personnalisés.

- Les machines de fabrication de gommes sont conçues pour automatiser la production de gommes de différentes formes, tailles et saveurs, ce qui permet aux fabricants de respecter plus facilement les spécifications de production. Ces machines sont disponibles en différentes tailles pour répondre aux différents besoins de production.

- L'industrie de la confiserie s'appuie sur des équipements de fabrication de bonbons gélifiés de haute qualité pour produire des bonbons gélifiés qui répondent aux attentes des clients. Les consommateurs apprécient une grande variété de bonbons gélifiés, y compris ceux adaptés aux différentes préférences alimentaires et aux expériences amusantes et texturées.

- Les équipements de production de gommes, tels que les moules à gommes et les machines à fabriquer des gommes, jouent un rôle crucial en garantissant la qualité et l'homogénéité des gommes. Le développement de recettes uniques pour différentes textures, saveurs et options alimentaires, telles que les gommes végétariennes ou végétaliennes, est essentiel à la création de différents types de gommes.

- Avec la bonne machine à fabriquer des gommes, les fabricants peuvent produire des gommes de haute qualité avec des possibilités infinies de saveurs et de formes, y compris des gommes fonctionnelles avec des vitamines, des plantes ou d'autres ingrédients bénéfiques pour la santé ajoutés.

Équipement de fabrication de gommes

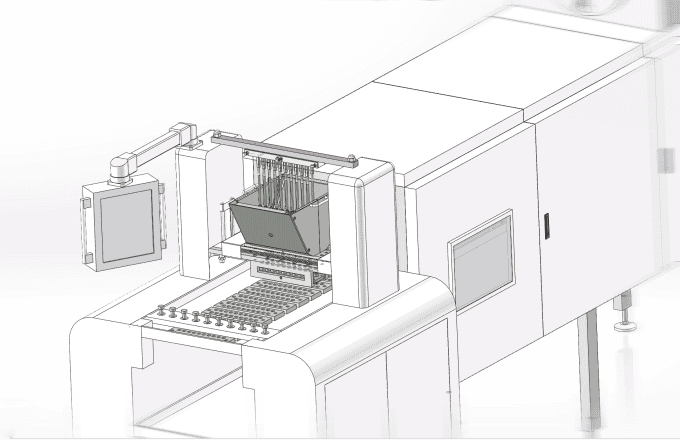

- Les machines à fabriquer des gommes sont des équipements spécialisés utilisés dans l'industrie de la confiserie pour produire des gommes. bonbonsCes machines sont conçues pour produire des bonbons à la gomme, y compris des oursons en gomme, des vers en gomme et d'autres formes. Ces machines sont disponibles en différentes tailles pour s'adapter aux différentes capacités de production et aux besoins de personnalisation.

- Une machine à fabriquer des gommes se compose généralement d'un mélangeur, d'un système de chauffage et d'un mécanisme de remplissage du moule, qui travaillent ensemble pour créer des gommes à la texture et à la forme précises. L'échangeur de chaleur de ces machines comprend souvent un paquet de plaques pour assurer un transfert de chaleur efficace pendant le traitement.

- Les machines de dépôt de gommes sont conçues pour déposer le mélange de gommes dans les moules, éliminant ainsi la nécessité d'une manipulation manuelle et réduisant la contamination croisée. Une ligne de production complète intègre des machines de dépôt, des mélangeurs, des moules et d'autres équipements spécialisés pour permettre une production de masse efficace et automatisée de gommes de formes et de types variés.

- Les équipements de production de gommes, tels que les cuves de dissolution du sucre et les systèmes de dosage automatique, sont également essentiels pour une production efficace de gommes. Une grande précision dans le dosage des ingrédients et le contrôle de la qualité est cruciale pour la production de gommes à mâcher. garantir une qualité constante et des gommes exemptes de contamination.

- Les machines de fabrication de gommes de Saintyco, par exemple, se caractérisent par une ingénierie de précision et un engagement fort en faveur de l'innovation dans la technologie de fabrication, et sont capables de produire de 20 000 à 200 000 gommes par heure.

Processus de fabrication des chewing-gums

- le procédé de fabrication de gommes comporte plusieurs étapes, notamment le mélange, le chauffage et le moulage, qui nécessitent un équipement spécialisé, une ingénierie de précision et une grande exactitude dans le dosage des ingrédients afin de garantir une qualité constante.

- Les machines de fabrication de gommes sont conçues pour automatiser ces étapes, garantissant ainsi la cohérence et la qualité de chaque lot de gommes. Au cours de la production, les fabricants ajoutent divers ingrédients tels que des arômes, des colorants ou des composants fonctionnels pour créer des produits variés et personnalisés.

- Le processus de fabrication implique également l'utilisation de divers ingrédients, tels que l'amidon, le sucre et les colorants alimentaires, qui doivent être mesurés et mélangés avec précision pour produire des gommes de haute qualité. Il est essentiel de suivre des recettes spécifiques pour les différents types de gommes, y compris les gommes végétariennes, végétaliennes et fonctionnelles avec des avantages supplémentaires pour la santé, afin d'obtenir la texture et les propriétés souhaitées.

- Les équipements de production de gommes, tels que les mélangeurs dynamiques en ligne et les tunnels de refroidissement, contribuent à rationaliser le processus de fabrication et à réduire le temps de production. Une ligne de production bien conçue intègre ces machines spécialisées, ce qui garantit une production de masse de gommes efficace, hygiénique et flexible.

- Avec l'équipement et le processus adéquats, les fabricants peuvent produire des gommes à la texture, à la forme et à la saveur parfaites.

Types de distributeurs de bonbons à la gomme

- Il existe différents types de machines à gommes, notamment des machines à fabriquer des gommes, des machines à déposer des gommes et des moules à gommes, chacune étant conçue pour répondre à des besoins de production spécifiques. Ces machines sont disponibles en différentes tailles pour répondre aux différents besoins de production.

- Gummy Star et Gummy Jumbo sont des exemples de machines à fabriquer des bonbons gélifiés qui offrent une ingénierie de précision et une production de grande capacité. Lors de la sélection d'un équipement, il est important de choisir une marque réputée pour sa qualité et sa fiabilité.

- Pilot Star est un programme d'entrée de gamme machine à fabriquer des gommes idéale pour la production à petite échelle et les entrepreneurs qui se lancent dans la production de bonbons gélifiés. La taille de la machine doit être prise en compte pour s'assurer qu'elle correspond à la production souhaitée.

- Les équipements auxiliaires, tels que les moules à gommes et les solutions d'emballage, complètent la production de gommes et améliorent l'efficacité. La livraison rapide et fiable de ces composants est cruciale pour une installation efficace et des opérations fluides.

- La technologie de moulage sans amidon de Tanis est un autre exemple d'équipement innovant de fabrication de bonbons gélifiés qui garantit une production pure et régulière. Cette innovation joue un rôle clé dans l'évolution des processus de fabrication des bonbons gélifiés.

- L'intégration de ces machines et équipements permet de créer une ligne de production complète, offrant ainsi une gamme complète de services. solution pour une fabrication efficace et flexible de gommes.

Principales caractéristiques à rechercher dans un Machine à bonbons gommeux

Lors de la sélection d'un machine à bonbons gélifiés pour votre entreprise de confiserie, il y a plusieurs caractéristiques clés à prendre en compte pour vous assurer de trouver l'équipement adapté à vos besoins en matière de production de bonbons gélifiés. Une machine de fabrication de bonbons gélifiés de haute qualité doit être capable de produire une large gamme de bonbons gélifiés, y compris des oursons gélifiés, des bonbons gélifiés aux vitamines et des bonbons gélifiés nutraceutiques, de formes et de tailles différentes.

L'une des caractéristiques les plus importantes à rechercher est la précision technique, qui permet à l'appareil de fournir des résultats cohérents et précis, minimisant ainsi le risque de contamination croisée et garantissant la production de gommes de haute qualité. L'appareil doit également être facile à utiliser et à nettoyer, avec une interface simple et intuitive qui vous permet d'ajuster facilement les spécifications de production et les recettes.

Une autre caractéristique essentielle à prendre en compte est la capacité de la machine à produire des gommes dans une infinité de formes, de tailles et d'arômes, ce qui vous donne la possibilité de créer des produits uniques et innovants qui se démarquent sur le marché. La machine à déposer les gommes doit également être capable de produire un volume élevé de gommes par heure, ce qui en fait un équipement de confiserie essentiel pour la fabrication de gommes à grande échelle.

Outre ces caractéristiques, il est également important de tenir compte de l'efficacité, de la productivité et de la capacité de la machine à minimiser les déchets et à réduire les coûts de production. Une bonne machine à fabriquer des bonbons gélifiés doit pouvoir vous aider à économiser de l'argent, du temps et des efforts, tout en produisant des résultats de haute qualité et en vous permettant d'explorer des recettes de bonbons gélifiés nouvelles et innovantes.

Lors de l'évaluation des différentes les machines à bonbons gélifiés, Veillez à rechercher des caractéristiques telles que des systèmes de mélange et de chauffage avancés, un contrôle précis de la température et une construction robuste capable de résister aux exigences d'une production de gommes à mâcher en grande quantité. La machine doit également être conçue dans un souci de sécurité et d'hygiène, avec des surfaces faciles à nettoyer et un système fermé qui minimise le risque de contamination.

En tenant compte de ces caractéristiques clés et en effectuant des recherches, vous pourrez trouver le produit idéal. machine à bonbons gélifiés pour votre entreprise, une machine qui vous aidera à produire des gommes de haute qualité, à augmenter votre productivité et à apporter de la joie et du plaisir à vos clients. Que vous soyez un petit fabricant de gommes ou une grande entreprise de confiserie, la bonne machine à fabriquer des gommes peut faire toute la différence dans votre production de gommes et vous aider à réussir dans le monde compétitif de la confiserie.

Il est également important de tenir compte de l'assistance à la clientèle et du service offert par le fabricant, ainsi que de la disponibilité des pièces détachées et des services d'entretien. Un bon fabricant doit être en mesure de vous fournir une assistance et des conseils complets, afin de vous aider à tirer le meilleur parti possible de votre appareil. machine à bonbons gélifiés et s'assurer qu'il continue à fournir des résultats de haute qualité pour les années à venir.

En conclusion, lorsque l'on cherche un machine à bonbons gélifiésDans le cas d'une machine à gommes, tenez compte des principales caractéristiques qui vous permettront de produire des gommes de haute qualité, notamment la précision technique, la polyvalence, l'efficacité et la sécurité. En faisant vos recherches et en trouvant la machine qui convient à votre entreprise, vous pourrez améliorer votre production de gommes, proposer des produits innovants et délicieux à vos clients et réussir dans l'industrie de la confiserie.

Avantages de la production automatisée de bonbons gélifiés

- La production automatisée de bonbons gélifiés offre plusieurs avantages, notamment une efficacité, une régularité et une qualité accrues, ainsi qu'une réduction des coûts de main-d'œuvre et de la contamination croisée. Les innovations en matière d'automatisation améliorent encore l'efficacité de la production et la qualité des produits.

- Les machines à fabriquer des gommes peuvent produire des gommes de différentes formes, tailles et saveurs, ce qui permet aux fabricants de répondre plus facilement aux demandes des clients et aux spécifications de production. Après tout, les consommateurs apprécient la grande variété de gommes produites par des processus automatisés.

- La production automatisée permet également aux fabricants de produire des gommes nutraceutiques et fonctionnelles, telles que des gommes vitaminées enrichies d'ingrédients bénéfiques pour la santé, avec un dosage précis et une grande exactitude afin de garantir une qualité constante.

- Avec la bonne machine à fabriquer des gommes, les fabricants peuvent améliorer leur production de gommes et garantir une livraison fiable de gommes de haute qualité qui répondent aux attentes des clients.

- En outre, la production automatisée peut contribuer à réduire les efforts et l'argent consacrés à la manipulation manuelle et au contrôle de la qualité.

Optimiser la production de bonbons gélifiés avec la bonne machine

Pour optimiser la production de bonbons gélifiés, les fabricants doivent choisir la machine de fabrication de bonbons gélifiés qui répond à leurs spécifications et à leurs besoins de production. Le choix d'un équipement d'une marque de confiance est essentiel pour l'assurance de la qualité et la fiabilité à long terme.

La prise en compte de facteurs tels que la capacité de production, la manipulation des ingrédients et la précision technique peut aider les fabricants à sélectionner la machine idéale pour leur activité.

Les équipements de production de bonbons gélifiés, tels que les moules à bonbons gélifiés et les solutions d'emballage, doivent également être pris en compte pour améliorer l'efficacité et la qualité. L'intégration de ces composants dans une ligne de production complète permet de rationaliser les opérations, d'automatiser et de produire une grande variété de produits à base de chewing-gum.

Avec la machine et l'équipement adéquats, les fabricants peuvent produire des gommes de haute qualité avec des possibilités infinies de saveurs et de formes, et les livrer aux clients avec joie et satisfaction. Des services de livraison et de configuration fiables garantissent une installation sans heurts et une assistance continue.

En investissant dans des équipements de fabrication de bonbons gélifiés innovants, les fabricants peuvent renforcer leur activité et rester compétitifs dans l'industrie de la confiserie.

Si vous souhaitez en savoir plus ou acheter une machine à bonbons gélifiés, Veuillez nous contacter pour plus d'informations.

Liens de référence:

1. Fabrication de denrées alimentaires

fabrication de produits alimentaires.com