La dulce ciencia de las mariposas de goma

Hacer mariposas de goma es mucho más que mezclar ingredientes. Es un proceso complejo que combina la ciencia de los alimentos, la química y la ingeniería. Cada paso afecta al producto final. Desde la textura masticable hasta los colores brillantes, cada elemento se controla cuidadosamente. Este artículo explora la tecnología que convierte los ingredientes básicos en mariposas de goma estables, sabrosas y con la forma perfecta.

Examinaremos estas importantes áreas:

-

La ciencia detrás de la creación del textura masticable.

-

Cómo afecta el calor a las fases de cocción y cuajado.

-

Los métodos de ingeniería utilizados para dar forma y moldear.

-

La química de añadir sabores y colores con éxito.

-

Pasos importantes del control de calidad y duración del producto.

El desglose de la matriz gomosa

Cada gominola empieza con su receta. Cuando los hidrocoloides, los azúcares y los ácidos se mezclan, crean un complejo sistema llamado matriz de la gominola. Cada ingrediente tiene una función específica. Comprender estas funciones es clave para controlar el resultado final del producto.

La columna vertebral hidrocoloide

La gelatina es el principal gelificante de las gominolas tradicionales. Esta proteína procede del colágeno. Su estructura única de triple hélice crea la clásica textura de gominola que conocemos y adoramos.

La característica más importante de la gelatina es su fuerza Bloom. Este número nos indica lo firme y fuerte que será el gel. Para que las gominolas tengan ese tacto masticable y elástico perfecto, utilizamos gelatina con un Bloom de 220-250. Un Bloom más bajo hace geles más blandos y débiles. Los números Bloom más bajos hacen geles más blandos y débiles. Los números más altos pueden hacer que la textura sea demasiado dura y gomosa.

El proceso comienza mezclando gelatina con agua. Esto permite que las cadenas de proteínas se desenrollen. Cuando calentamos la mezcla durante la cocción, estas cadenas se extienden completamente en la solución azucarada. Al enfriarse, las cadenas vuelven a unirse y se entrecruzan. Atrapan el agua y forman una red de gel tridimensional estable. Esto es lo que da a las gominolas su estructura.

La gelatina es estándar, pero existen otras opciones. La pectina crea una textura diferente. Produce un bocado más "corto" y tierno, típico de las gelatinas de fruta, en lugar de las gominolas masticables.

|

Atributo

|

Gelatina

|

Pectina

|

|

Fuente

|

Animal (Colágeno)

|

Planta (principalmente cáscaras de cítricos, manzanas)

|

|

Textura

|

Masticable, elástico, se funde cerca de la temperatura corporal

|

Corto, tierno, quebradizo

|

|

Establecer necesidades

|

Se endurece al enfriarse

|

Requiere un pH específico y un alto contenido de azúcar

|

|

Sensación en boca

|

Derretimiento lento y persistente

|

Rotura limpia, liberación más rápida del sabor

|

La ciencia del azúcar

El azúcar en las gominolas hace mucho más que añadir dulzor. Es crucial para la textura y para mantener estable el producto.

La sacarosa, o azúcar de mesa normal, aporta el principal sabor limpio y dulce. Pero utilizar sólo sacarosa causaría problemas. Con el tiempo, el producto quedaría arenoso y cristalizado.

Por eso añadimos jarabe de glucosa, también llamado jarabe de maíz. Éste actúa como "adulterante". El jarabe de glucosa contiene cadenas de azúcar de diferentes longitudes, como dextrinas, maltosa y glucosa. Estas moléculas variadas se interponen en el camino de las moléculas de sacarosa que intentan formar estructuras ordenadas. Esto evita la cristalización y mantiene la textura suave y uniforme.

También solemos utilizar azúcar invertido, que es una mezcla de glucosa y fructosa. Este ingrediente atrae y retiene muy bien el agua. Esta propiedad ayuda a mantener blandas las gominolas y evita que se sequen. Además, prolonga la vida útil del producto.

La función del ácido

Los ácidos de calidad alimentaria son esenciales para hacer gominolas. Utilizamos principalmente ácido cítrico y ácido málico. Tienen tres funciones importantes.

En primer lugar, añaden la acidez que equilibra el intenso dulzor de todo ese azúcar. A menudo combinamos el tipo de ácido con el sabor. El ácido cítrico va bien con los sabores cítricos. El ácido málico aporta la acidez duradera que se encuentra en los sabores a manzana o bayas.

En segundo lugar, y lo más importante, el ácido controla el pH de la mezcla gomosa. La gelatina necesita un entorno ácido específico para fijarse correctamente y alcanzar su mejor fuerza de gel. Para las gominolas a base de gelatina, nuestro objetivo es un pH entre 3,4 y 3,6.

Por último, el ácido ayuda a conservar el producto. Al bajar el pH y reducir el agua disponible, contribuye a la estabilidad general frente a microbios nocivos.

El proceso de fabricación

La transformación de ingredientes líquidos en mariposas de goma acabadas implica múltiples etapas. La temperatura, el tiempo y la mecánica deben controlarse con precisión. Cada paso es fundamental y afecta a la calidad final.

Dosificación y cocción

Empezamos mezclando agua, azúcares y gelatina en grandes calderos calientes. A continuación, esta mezcla se cuece hasta un punto final preciso.

La cocción hace algo más que disolver ingredientes. Es una etapa de concentración. Calentamos la mezcla a una temperatura objetivo, normalmente entre 115-120°C (240-250°F). Así se consigue un contenido específico de sólidos totales.

Lo medimos en grados Brix, que indican el porcentaje de sólidos disueltos (principalmente azúcares) en la solución. Para que las gominolas se conserven bien y tengan la textura adecuada, nuestro objetivo es alcanzar entre 78 y 82 grados Brix. En esta fase, la mezcla pasa de ser un líquido turbio a un jarabe claro y muy espeso. Esto indica que se ha evaporado la cantidad adecuada de agua.

Dosificación de componentes volátiles

Añadimos ácidos, sabores y colores sólo después de que la mezcla se haya cocinado y enfriado ligeramente. Este momento es crucial.

Estos ingredientes son sensibles al calor. Añadirlos a las temperaturas máximas de cocción causaría graves problemas. Los sabores se evaporarían y perderían su fuerza. Muchos colores, especialmente los naturales, se volverían marrones o cambiarían por completo. Añadirlos después de la cocción garantiza que el producto final se mantenga vibrante y sabroso.

Depositar y moldear

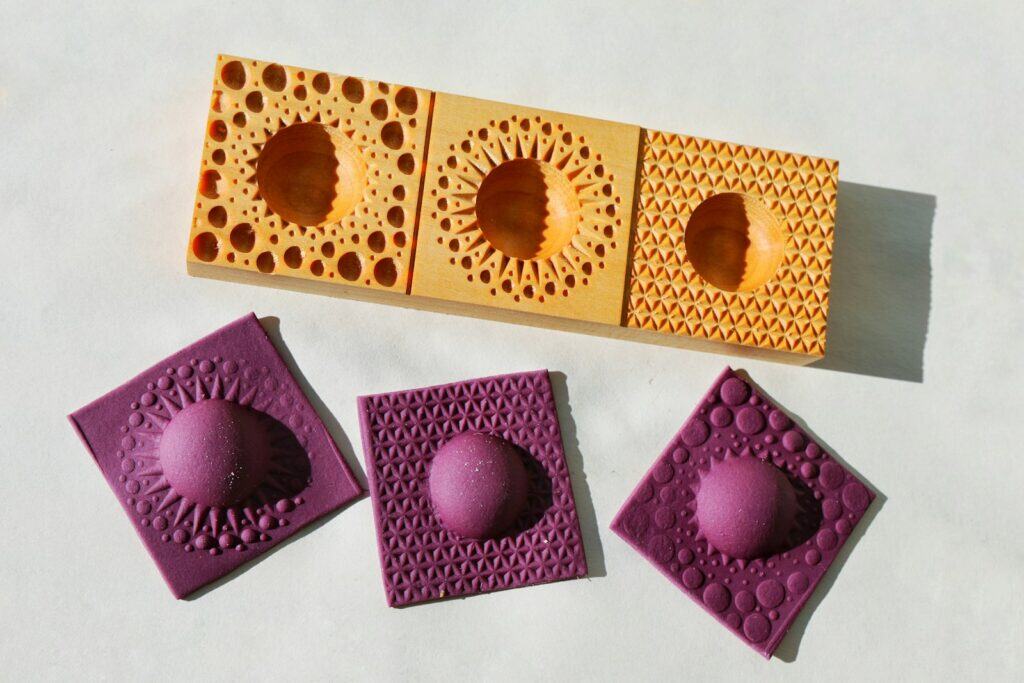

Dar forma a las mariposas de goma es un paso clave en la fabricación. Existen dos métodos industriales principales.

El método tradicional de gran volumen utiliza un sistema mogul de almidón. Las bandejas llenas de almidón alimentario se imprimen con moldes en forma de mariposa. A continuación, se vierte una mezcla de gominolas caliente en estas impresiones. El almidón hace dos cosas: mantiene la forma de la gominola y extrae una pequeña cantidad de humedad de la superficie. Así se forma una ligera piel.

Una opción más reciente utiliza moldes de silicona. Aquí, la mezcla va directamente a bandejas de silicona reutilizables y flexibles. Este método permite obtener detalles mucho más finos y un acabado más limpio y brillante. Es perfecto para los delicados dibujos de las alas de mariposa.

|

Factor

|

Sistema Starch Mogul

|

Moldes de silicona

|

|

Detalle Fidelidad

|

Inferior; produce formas más simples

|

Alta; excelente para diseños intrincados

|

|

Velocidad/Rendimiento

|

Muy alto; adecuado para la producción en serie

|

Más bajo; a menudo se utiliza para lotes más pequeños

|

|

Costo

|

Bajo coste recurrente (el almidón es reutilizable)

|

Elevada inversión inicial en moldes

|

|

Limpieza

|

Complejo; requiere tamizado/secado de almidón

|

Sencillo; los moldes se lavan fácilmente

|

|

Acabado

|

Mate, puede tener residuos de almidón

|

Superficie brillante y muy limpia

|

Fraguado y curado

Una vez moldeadas, las gominolas pasan a una "sala de secado" con condiciones cuidadosamente controladas. La temperatura y la humedad se regulan para facilitar el proceso final de fraguado y curado. Este proceso puede durar entre 24 y 48 horas.

Aquí se producen dos cambios importantes. En primer lugar, al bajar la temperatura, la red de gelatina se forma y se endurece. Este proceso se denomina gelificación.

Al mismo tiempo, se evapora una cantidad controlada de humedad de las gominolas. Este paso de reducción de la humedad reafirma el producto. Se transforma de un gel blando en el caramelo final, denso y masticable.

Acabado y pulido

Una vez curadas, las gominolas se desmoldan. En un sistema de almidón mogul, esto significa voltear y soplar las gominolas para eliminar todo el almidón sobrante.

El último paso suele ser un ligero pulido. Las gomitas se voltean en un tambor grande con una pequeña cantidad de agente pulidor. Puede ser aceite mineral alimentario o cera de carnauba. Así se evita que las piezas se peguen unas a otras en los paquetes y se consigue un brillo atractivo.

Ingeniería sensorial

Las mariposas de goma no sólo atraen nuestro sentido del tacto. Su sabor, su olor y su aspecto también importan. Estas características sensoriales no son accidentales. Están técnicamente diseñadas y controladas mediante una cuidadosa selección de ingredientes.

Sistemas de suministro de sabores

Para elegir entre sabores naturales y artificiales hay que sopesar el coste, la estabilidad y lo que quieren los consumidores. Los aromas artificiales suelen ser más fuertes y resisten mejor el calor. Los naturales proceden de plantas y son los preferidos para los productos de "etiqueta limpia".

Para los productos premium, utilizamos una técnica más avanzada llamada encapsulación de sabor. Pequeñas gotas de aceite aromatizante se recubren de una capa protectora. Esta capa evita que el sabor se descomponga al mezclarlo con la masa caliente. El verdadero beneficio llega cuando alguien mastica la gominola. Se rompe la cubierta y se libera una explosión de sabor fresco.

La combinación de ingredientes también ayuda. El sabor parece más intenso cuando el perfil ácido coincide con el tipo de sabor. Una gominola con sabor a limón sabe mejor con ácido cítrico. El sabor a manzana verde funciona mejor con ácido málico.

La paleta de colores

Crear el aspecto vibrante y multicolor de las mariposas de goma requiere un profundo conocimiento de los colorantes alimentarios.

Al igual que los aromas, los colorantes pueden ser artificiales (colorantes FD&C) o naturales. Los colorantes naturales proceden de fuentes como la cúrcuma (amarillo), el zumo de remolacha (rojo) y el extracto de espirulina (azul).

Los colores naturales plantean retos técnicos. Suelen ser más sensibles al calor, la luz y el pH que los artificiales. Por ejemplo, las antocianinas son pigmentos que se encuentran en la col roja o el saúco. Son excelentes colorantes naturales rojos y morados. Pero su color exacto puede cambiar drásticamente en función del pH final de la gominola.

Conseguir una distribución uniforme del color es otro paso fundamental. El colorante debe mezclarse bien en la masa. Así se evitan manchas, rayas o colores desiguales en el producto final.

Calidad y estabilidad

Una mariposa de goma de éxito debe ser perfecta en el momento de su elaboración y mantenerse así durante toda su vida útil. Para ello se necesitan control de calidad durante la producción. La receta también debe diseñarse para que sea estable a largo plazo.

Puntos críticos de control

A programa de garantía de calidad para la producción de gominolas se centra en varios puntos de control clave. Éstos garantizan la coherencia.

-

Inspección de materias primas: Comprobamos las materias primas entrantes, especialmente la fuerza Bloom de la gelatina y la pureza del azúcar. Esto influye directamente en la textura final.

-

Controles en curso: Durante la producción, controlamos constantemente la temperatura de la mezcla y los niveles de grados Brix. Cualquier desviación puede comprometer la textura y la estabilidad de todo el lote.

-

Pruebas de productos acabados: Las gominolas terminadas se someten a múltiples pruebas. Un analizador de textura mide la firmeza y la elasticidad para garantizar que cumplen las normas. También medimos la actividad del agua (aW). Se trata de la cantidad de agua "libre" disponible para el crecimiento de microbios nocivos. Nuestro objetivo es que la actividad del agua sea inferior a 0,80 para que el producto sea estable. Por último, un panel de degustación cualificado evalúa el sabor, la textura y el aspecto correctos del producto.

Factores de caducidad

La duración de las gominolas depende tanto de la receta como del envase. La baja actividad del agua, combinada con la acidez del producto, crea un entorno en el que la mayoría de las bacterias y el moho no pueden sobrevivir.

El envasado desempeña un último papel crucial. Debe bloquear eficazmente la humedad ambiental y el oxígeno. Un envase deficiente hará que las gominolas absorban humedad y se vuelvan pegajosas o pierdan humedad y se vuelvan duras y resistentes.

Por experiencia, los problemas de textura más comunes son la "transpiración" (sinéresis), por la que se escapa el agua debido a un equilibrio ácido o un proceso de cocción inadecuados. El otro problema es la dureza excesiva debida a un secado excesivo durante el curado o a un envasado inadecuado.

Un capricho de ingeniería

La mariposa de gominola parece una golosina sencilla y divertida. Pero en realidad es un testimonio de la precisión de la ciencia alimentaria y la ingeniería de procesos. Desde las interacciones moleculares en la mezcla inicial hasta el control de la temperatura en las salas de secado, cada paso se gestiona cuidadosamente. El producto final equilibra la química, la física y la ciencia sensorial. Todo ello se diseña para ofrecer una experiencia consistente y agradable. Se trata de una tecnología alimentaria extraordinaria, plasmada en una forma sencilla y dulce.

Enlaces de referencia:

- Gelatina - ScienceDirect Topics https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/gelatin

- Bloom (prueba) - Wikipedia https://en.wikipedia.org/wiki/Bloom_(test)

- Estabilidad de almacenamiento a largo plazo de geles de gelatina tipo A y tipo B: El efecto de la fuerza Bloom y los co-solutos - ScienceDirect https://www.sciencedirect.com/science/article/pii/S0268005X22000558

- Evaluación de la resistencia a la floración de la gelatina en las propiedades de los hidrogeles de metacriloilo de gelatina - ScienceDirect https://www.sciencedirect.com/science/article/abs/pii/S1751616124001413

- Humedad y vida útil en los dulces - PubMed (NIH) https://pubmed.ncbi.nlm.nih.gov/20112158/

- Relaciones Hídricas en los Dulces - Actividad Hídrica en los Alimentos - Wiley Online Library https://onlinelibrary.wiley.com/doi/10.1002/9781118765982.ch20

- Actividad y calidad del agua en los productos de confitería - Industria alimentaria en Asia y el Pacífico https://www.apfoodonline.com/industry/water-activity-and-quality-in-confectionery/

- Actividad acuática, golosinas y confitería: Maximizar el sabor y la textura - AQUALAB https://aqualab.com/en/knowledge-base/market-insights/water-activity-candy-and-confectionery

- Actividad del agua | Barry Callebaut https://www.barry-callebaut.com/en/news-events/water-activity

- Vida útil: Establecimiento de objetivos y evaluación de productos - Chocolate Academy https://www.chocolate-academy.com/en-US/shelf-life-setting-goals-and-evaluating-products