The production of gummy bears is a complex process that involves a series of mechanical, thermal, and sometimes hydraulic operations. Operating a gummy bear machine requires a significant amount of energy to ensure each step, from mixing to molding and packaging, runs smoothly and efficiently.

This article will discuss the various energy requirements for operating a gummy bear machine.

1. Mixing and Heating

The initial stage of gummy bear production involves mixing the ingredients and heating them to the appropriate temperature. This process requires energy to power the mixers and heating elements. The energy input ensures that ingredients like sugar, gelatin, and flavorings are thoroughly combined and the mixture reaches the correct temperature for molding.

2. Cooling Systems

After the gummy mixture is prepared, it needs to be cooled and set in molds. This step often involves energy-intensive cooling systems that rapidly decrease the temperature to facilitate the solidification of the gummy mass. The type of cooling system (air-based, water-based, or refrigerant-based) will influence the energy requirements.

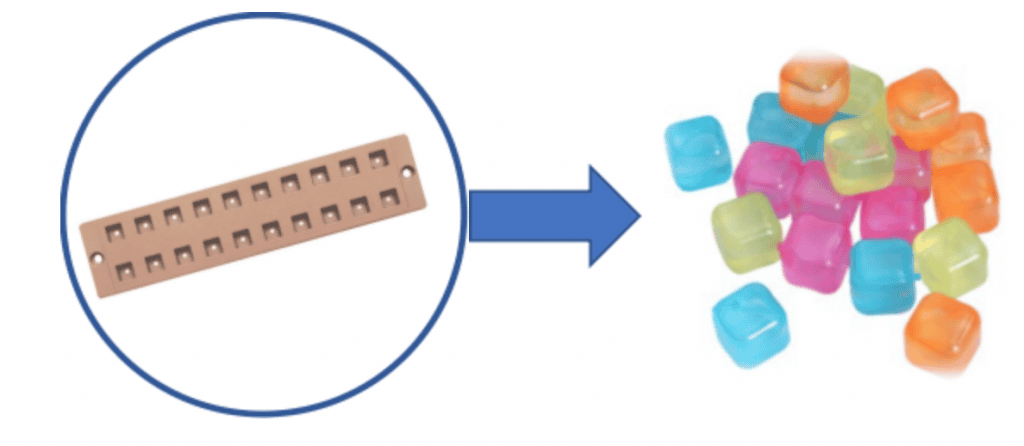

3. Mold and Machine Operation

The molds used in gummy bear machines, as well as the mechanical parts of the machine itself, require energy to operate. This includes energy for the motors that control the movement of the molds, the injection of the gummy mixture, and the ejection of the formed gummies.

4. Vacuum and Pressure Systems

Some gummy bear machines use vacuum or pressure systems to assist in the molding process, ensuring that the gummy mixture fills the mold cavities completely and without air bubbles. These systems add to the overall energy consumption of the machine.

5. Demolding Process

The demolding process, where the formed gummies are released from the molds, may require energy for the operation of ejector pins or other mechanical devices that facilitate the release.

6. Conveyor Systems

Conveyor systems that transport the gummy bears from the molding area to the packaging area also consume energy. These systems are crucial for the continuous operation of the production line.

7. Packaging Machines

The energy requirements of a gummy bear machine also include the power needed for packaging machines that wrap, seal, and package the gummy bears for distribution.

8. Quality Control and Monitoring

Quality control processes, which may involve automated sensors and monitoring systems to check the consistency and quality of the gummies, add to the energy needs of the operation.

9. Lighting and Facility Infrastructure

The production facility itself requires energy for lighting, climate control, and other infrastructure elements that support the operation of the gummy bear machine.

10. Energy-Efficient Technologies

To reduce energy consumption, some manufacturers invest in energy-efficient technologies such as variable frequency drives (VFDs) for motors, energy recovery systems, and optimized insulation for heating and cooling systems.

11. Scale of Production

The energy requirements will vary depending on the scale of production. Larger machines that produce more gummies per hour will naturally have higher energy demands than smaller machines.

12. Regulatory and Environmental Considerations

Manufacturers must also consider the energy efficiency regulations and environmental impact of their operations, which may influence the choice of machinery and production practices.

Conclusion

Operating a gummy bear machine involves considerable energy use across various stages of the production process. From mixing and heating to cooling, molding, and packaging, each step requires a careful balance of energy input to ensure efficient production and quality output. As the industry evolves, there is a growing focus on energy-efficient technologies and practices to minimize the environmental footprint of gummy bear production.