Введение в высокоэффективное пищевое оборудование

Высокопроизводительное пищевое оборудование играет ключевую роль в современной линии по производству вафельного печенья, позволяя производителям добиваться высокой производительности и стабильного качества продукции. Линия по производству вафельного печенья, также называемая линией по производству вафель, объединяет несколько этапов производства вафельного печенья в упорядоченный, автоматизированный процесс. Используя передовые технологии и автоматизированные производственные линии, производители могут значительно сократить ручной труд, увеличить скорость производства и обеспечить однородность каждой партии. Вафельный В процессе производства бисквита используется специализированное оборудование такие как машины для нанесения крема и машины для нарезки вафель, которые работают вместе, чтобы производить вкусное и высококачественное вафельное печенье с удивительной эффективностью. Эта бесшовная интеграция машин и технологий не только улучшает общий производственный процесс, но и гарантирует, что каждое вафельное печенье соответствует самым высоким стандартам вкуса и внешнего вида.

Обзор линии по производству вафель

Разработанная нами автоматическая линия по производству серийных вафель представляет собой современную производственную систему, объединяющую передовые технологии автоматизации и мастерство пищевой промышленности. Она специально разработана для крупномасштабного производства высококачественного вафельного печенья, вафельных рулетов, вафель с начинкой и других серийных продуктов. Вся производственная линия имеет модульную конструкцию и может быть гибко настроена в соответствии с требованиями заказчика по производительности (от 50 кг до 500 кг в час). Она совместима с различными рецептурами и спецификациями, удовлетворяя производственные потребности от традиционных оригинальных вкусов до высококлассных индивидуальных вафельных продуктов.

Эта производственная линия отличается усовершенствованной структурой и компактностью, вдохновленной технологическими усовершенствованиями и планировкой существующих заводов. Созданная специально для внутреннего рынка, она представляет собой продукт нового поколения, разработанный исключительно нашей китайской командой, демонстрируя местный опыт и инновации в области оборудования для производства пластин.

Основные компоненты линии по производству бисквита

Современная линия по производству бисквитов, особенно линия по производству вафельного печенья, состоит из нескольких важнейших элементов технологического оборудования, которые работают слаженно, обеспечивая высокое качество вафельного печенья. Процесс начинается с тестомеса, первого технологическое оборудование для производства вафель, Благодаря этому все ингредиенты тщательно перемешиваются для получения однородного вафельного листа. Миксер для крема отвечает за смешивание сахара, масла и других ингредиентов в соответствии с точными технологическими предписаниями, создавая идеальный крем для намазывания. Вафельница, или печь для выпечки, является сердцем производственной линии, обеспечивая равномерный нагрев и создавая вафельные блоки с однородным цветом. После выпечки машина для охлаждения вафельных листов бережно охлаждает их, чтобы сохранить их текстуру и предотвратить поломку. Машина для нанесения крема равномерно наносит слой крема, а машина для резки вафель, или резательная машина, нарезает готовый продукт на точные формы и размеры. Каждая машина в производственной линии разработана для обеспечения надежности, эффективности и превосходного качества продукции, гарантируя, что каждое вафельное печенье соответствует строгим стандартам.

Основные преимущества

- Эффективное и стабильное производство

- Высокая производительность: Производственная линия стандартной конфигурации может производить 80-150 кг вафельных изделий в час, а высокотехнологичная модель может достигать 200-500 кг, увеличивая производственную мощность более чем на 30% по сравнению с традиционным оборудованием.

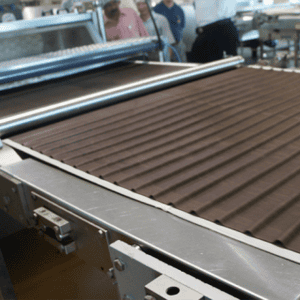

- Возможность непрерывной работы: Применяя импортные износостойкие конвейерные ленты и интеллектуальные системы контроля температуры, поддерживая 24-часовое непрерывное производство, с общей эффективностью оборудования (OEE) стабильно выше 90%.

- Энергосберегающий дизайн: Тепловая эффективность увеличена до 85%, что позволяет снизить энергопотребление на 15-20% по сравнению со средним показателем по отрасли, что позволяет ежегодно экономить значительные затраты на электроэнергию.

- Разумная структура носителя штампа и научный подбор: Оборудование имеет разумную структуру носителя матрицы и научный подбор нагревательных компонентов, что обеспечивает равномерный цвет нагрева, стабильное качество продукции и способствует высокой скорости производства готовой продукции.

- Превосходно Контроль качества продукции

- Точная система контроля температуры: Используя технологию интеллектуального температурного контроля PID, точность температурного контроля печи достигает ±1℃, обеспечивая равномерный цвет и хрустящий вкус вафельных листов.

- Точная регулировка толщины: Зазор между прижимными роликами контролируется серводвигателями, диапазон регулировки толщины вафельного листа составляет 0,3-3 мм, точность до ±0,05 мм.

- Автоматическая проверка качества: Оснащен системой визуального контроля высокой четкости, которая может автоматически определять и отбраковывать неквалифицированную продукцию, с коэффициентом прохождения стабильно выше 99.5%.

- Высокий процент готовой продукции и сертифицированных товаров: Производственная линия обеспечивает высокую скорость выпуска готовой продукции (не менее 98%), что гарантирует высокую долю сертифицированной продукции. Поддерживается высокая скорость формовки, что очень важно для эффективного производства и стабильного качества продукции.

- Высокая степень автоматизации и интеллекта

- Полностью автоматический процесс работы: От смешивания сырья до упаковки готовой продукции - весь процесс автоматизирован, и для контроля всей производственной линии требуется всего 2-3 человека.

- Интеллектуальная сенсорная система управления: 10,1-дюймовый сенсорный экран с человеко-машинным интерфейсом, встроенная функция хранения более 100 рецептур продуктов, позволяющая переключать параметры производства одним нажатием кнопки.

- Функция удаленного мониторинга: Поддержка IoT-соединения, что позволяет удаленно контролировать состояние производства, просматривать данные о работе и предупреждать о неисправностях через мобильные телефоны или компьютеры.

- Проектирование в области безопасности, гигиены и соответствия нормативным требованиям

- Материалы пищевого класса: Все детали, контактирующие с пищевыми продуктами, изготовлены из нержавеющей стали марки 304 и пищевого силикагеля, соответствующих международным стандартам, таким как FDA и EU 10/2011. Для ключевых компонентов применяется превосходный выбор материалов, а рама машины изготовлена из стали, соответствующей международным стандартам, для повышения долговечности и безопасности.

- Легко очищаемая конструкция: Поверхность оборудования отполирована электролитическим способом, оснащена системой очистки CIP на месте, что сокращает время очистки на 40%.

- Система защиты безопасности: Вся машина оснащена кнопками аварийной остановки, защитными ограждениями и световыми завесами безопасности, прошедшими сертификацию CE, ISO22000 и другие сертификаты. Оборудование рассчитано на надежную работу и простое обслуживание, обеспечивая стабильную работу и минимальное время простоя.

Производственная линия спроектирована таким образом, чтобы минимизировать воздействие на окружающую среду, уделяя особое внимание энергоэффективности и сокращению отходов на протяжении всего производственного процесса. Это способствует устойчивому развитию производства и снижению общего воздействия на окружающую среду.

Настройка производственной линии

Персонализация производственных линий - ключевое преимущество современных производство вафельного печенья, Это позволяет производителям быстро адаптироваться к различным рецептурам, типам продукции и требованиям рынка. Настраивая такие элементы, как система смешивания, миксер для крема и печь для приготовления вафель, производители могут точно настроить производственную линию под уникальные рецептуры и производственные требования. Независимо от того, производятся ли классические плоские вафли или инновационные бисквитные вафли, гибкость автоматизированных производственных линий и сенсорные экраны управления позволяют легко настраивать параметры производства и переключаться между продуктами. Передовые технологии позволяют легко интегрировать новые функции и быстро реагировать на изменение потребительских предпочтений, гарантируя, что производственная линия остается эффективной и конкурентоспособной. Такая адаптивность не только способствует созданию разнообразного ассортимента вафельного печенья, но и повышает общую эффективность производства и качество продукции.

Основные функции и технические параметры

- Система обработки сырья

- Несколько комплектов смесительных устройств: 2-4 комплекта емкостей для смешивания из нержавеющей стали объемом 50-200 л, поддерживающих одновременное смешивание различных видов сырья.

- Функция автоматической подачи: Винтовой автоматический питатель, который может точно контролировать количество подаваемого сырья с погрешностью ≤1%.

- Постоянный контроль температуры: Емкость для смешивания оснащена рубашкой постоянной температуры, с диапазоном контроля температуры 20-60℃, что обеспечивает стабильность теста.

- В системе используется отдельная система подачи и автоматической циркуляции для повышения эффективности и качества продукта в процессе смешивания.

- Система для выпечки вафель

- Способы выпечки: Различные варианты, включая электрический нагрев/газовый нагрев/теплопроводный нагрев масла.

- Температура выпечки: Регулируется от комнатной температуры до 300℃, с независимым контролем температуры в разных зонах.

- Скорость выпечки: плавная регулировка скорости 0,5-5 м/мин, адаптирующаяся к потребностям продуктов различной толщины.

- Технические характеристики пресс-формы: Различные формы пресс-форм (квадратные, круглые, специальные формы) могут быть настроены, с диапазоном размеров 50-150 мм.

- Печь оснащена высококачественными пекарскими плитами и научно подобранными нагревательными компонентами, обеспечивающими равномерное распределение тепла и стабильные результаты выпечки.

- Система охлаждения и ламинирования

- Многослойный охлаждающий канал: 3-5 слоев сетчатых охлаждающих лент из нержавеющей стали, с регулируемым временем охлаждения.

- Функция автоматического ламинирования: Серводвигатель контролирует точность ламинирования, что позволяет осуществлять точное ламинирование 2-10 слоев вафельных листов.

- Система контроля натяжения: Автоматически регулирует натяжение сетчатого ремня, чтобы предотвратить разрыв вафельных листов.

- Градирня используется для естественного охлаждения вафельных блоков, сохраняя качество продукции за счет контроля температуры в процессе охлаждения.

- Система заправки и резки

- Несколько комплектов устройств для розлива: 2-6 комплектов независимых насосов для розлива, которые могут осуществлять одновременный розлив нескольких вкусов.

- Способы резки: Два режима резки: круглый нож/прямой нож, с регулируемым размером резки 50-200 мм.

- Переработка крошки: Оснащен устройством для всасывания пыли под отрицательным давлением, скорость переработки составляет более 95%.

- Система управления

- Основной контроллер: Используется система управления PLC со скоростью реакции ≤0,1 мс.

- Запись данных: Автоматическая запись 30 дней производственных данных с поддержкой экспорта на U-диск.

- Диагностика неисправностей: Оснащен интеллектуальной функцией диагностики неисправностей, которая может отображать точки неисправности и предложения по их устранению.

- Система электропитания разработана таким образом, что в некоторых процессах вместо электричества используется сжатый воздух, что снижает общее потребление энергии.

Подробный процесс производства

- Этап подготовки сырья

- Поместите сырье, такое как мука, крахмал, масло и сахар, на склад сырья в соответствии с формульным соотношением.

- Автоматическая система взвешивания точно измеряет каждый компонент, с погрешностью в пределах ±0,5%.

- Жидкое сырье подается в смесительный бак по трубопроводам с постоянной температурой для обеспечения стабильной температуры.

- Этап приготовления теста

- Сырье поступает в смесительный бак в заданном порядке, сначала перемешивается на низкой скорости в течение 3 минут, затем перемешивается на высокой скорости в течение 5-8 минут.

- В процессе перемешивания автоматически определяется вязкость теста, и скорость перемешивания регулируется в режиме реального времени.

- Приготовленное тесто попадает в емкость для хранения и остается стоять при постоянной температуре 40-50℃.

- Этап выпечки и формовки

- Тесто равномерно распределяется по форме для выпечки с помощью дозирующего насоса.

- Войдите в туннельную печь, пройдя три этапа: зону предварительного нагрева (100-150℃), зону выпечки (200-280℃) и зону настройки (150-180℃).

- Формирование вафельного блока достигается благодаря точному контролю процесса выпечки, а высококачественные нагревательные компоненты обеспечивают равномерное окрашивание и текстуру.

- Выпеченные вафельные листы отделяются устройством для распалубки и поступают в систему охлаждения.

- Этап охлаждения и ламинирования

- Листовые пластины проходят через многослойный канал охлаждения, при этом температура снижается со 120℃ до комнатной (около 25℃).

- Для естественного охлаждения блока вафель используется градирня, а машина на этом этапе работает медленно, чтобы обеспечить качество и предотвратить повреждения.

- Охлажденные пластины точно выравниваются с помощью системы фотоэлектрического позиционирования.

- Автоматическое ламинирование в соответствии с заданным количеством слоев, точность ламинирования контролируется в пределах ±1 мм.

- Этап наполнения и резки

- Заготовки ламинированных пластин проходят через станцию заполнения, и заполняющий насос равномерно впрыскивает наполнитель в слои.

- Излишки наполнителя обрабатываются скребком для обеспечения ровной поверхности.

- Введите систему резки, точно отрежьте по заданному размеру и одновременно удалите边角料.

- Этап проверки и вывода

- Нарезанная готовая продукция проходит через систему визуального контроля, чтобы отбраковать изделия с деформацией, отсутствующими углами и неравномерным заполнением.

- Квалифицированные продукты подаются на конвейерную ленту в зону упаковки.

- Производственные данные обновляются в режиме реального времени, отображая на центральном экране управления такие ключевые показатели, как дневная производительность и коэффициент пропуска.

Машина для производства вафельного печенья и процесс изготовления вафельного печенья обеспечивают минимальное ручное вмешательство и эффективное крупномасштабное производство вафельного печенья.

Процесс производства пластин

Процесс производства вафель представляет собой тщательно выверенную последовательность этапов, каждый из которых поддерживается передовыми технологиями и высокоэффективными машинами. Он начинается с подготовки сырья, которое смешивается в гладкое вафельное тесто с помощью автоматизированных систем смешивания. Затем тесто выкладывается на пекарские плиты в вафельной печи, где при равномерном нагреве из него выпекаются тонкие хрустящие вафли. После выпечки вафельные листы передаются в машину для охлаждения вафельных листов, которая постепенно снижает их температуру, чтобы предотвратить деформацию и сохранить нежную текстуру. После охлаждения машина для нанесения крема наносит равномерный слой крема между вафельными листами, создавая фирменную многослойную структуру вафельного печенья. Затем собранные листы разрезаются на отдельные вафельные печенья с помощью машины для резки вафель, обеспечивающей точные размеры и чистые края. На протяжении всего производственного процесса автоматизированные производственные линии и сенсорные экраны управления сводят к минимуму ручное вмешательство, что позволяет добиться высокой эффективности, надежности и масштабируемости производства вафель, неизменно обеспечивая превосходный конечный продукт.

Охлаждение и упаковка

Охлаждение и упаковка - важнейшие этапы процесса производства вафельного печенья, напрямую влияющие на качество и срок хранения готового продукта. После выпечки вафельные листы поступают в машину для охлаждения вафельных листов, которая постепенно охлаждает их до стабильной температуры, предотвращая деформацию и сохраняя хрустящую текстуру. После охлаждения вафельные листы наполняются кремом и разрезаются на отдельные вафельные печенья, готовые к упаковке. Для эффективной упаковки вафельного печенья используются упаковочные машины с возможностью выбора различных форматов упаковки в соответствии с потребностями рынка. Эти машины отличаются надежностью и скоростью, гарантируя защиту каждого вафельного печенья от влаги и загрязнений, а также сохранение восхитительного вкуса и свежести от момента производства до попадания к потребителю. Интеграция передовых машин для охлаждения и упаковки в производственный процесс гарантирует, что каждое вафельное печенье попадет на рынок в оптимальном состоянии.

Применяемый ассортимент продукции

- Традиционное вафельное печенье: квадратные вафли, круглые вафли, вафли специальной формы.

- Вафли с начинкой: однослойная начинка, многослойная начинка, начинка со смешанным вкусом.

- Вафельные рулоны: прямые, спиральные, вафельные рулоны с наполнителем.

- Индивидуальная продукция: может разрабатывать вафельные изделия специальной формы и структуры в соответствии с требованиями заказчика.

Услуги и поддержка

- Монтаж и ввод в эксплуатацию: Профессиональная техническая команда обеспечивает установку и ввод в эксплуатацию на месте, чтобы оборудование достигло наилучшего рабочего состояния.

- Обучение персонала: Обеспечивает полное обучение по эксплуатации, техническому обслуживанию и ремонту, чтобы сотрудники заказчика овладели мастерством.

- Гарантия качества: 18 месяцев гарантии на всю машину, 24 месяца гарантии на основные компоненты.

- Поставка запасных частей: Создает региональные центры запасных частей, чтобы обеспечить доставку основных запасных частей в течение 48 часов.

- Техническое обновление: Предоставляет услуги по техническому обновлению на протяжении всей жизни, чтобы оборудование долгое время поддерживало передовой уровень.

Для получения более подробной технической информации или индивидуальных решений о линии по производству вафель, пожалуйста, свяжитесь с нашим отделом продаж, и мы предоставим вам профессиональные консультации и решения.