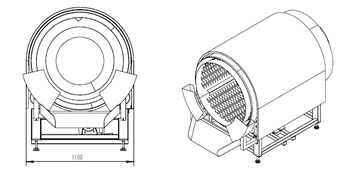

Sugar Sanding Machine: The Perfect Finish for Your Candies

Product Overview: The Sugar Sanding Machine, also known as a sugar roller, is an essential piece of equipment in the gummy candy production line. It applies a fine layer of sugar to the gummy surface, preventing stickiness and enhancing the texture and appearance of the final product. Crafted from stainless steel 304 for durability and hygiene, this machine is designed for ease of use and reliability.

Key Features & Benefits:

- Health and Safety Standards: Constructed with SUS 304 material for superior health and safety compliance.

- Automatic Control: Features an automatic control system for consistent operation with minimal manual intervention.

- High Quality & Competitive Pricing: Combines high-quality performance with cost-effective pricing.

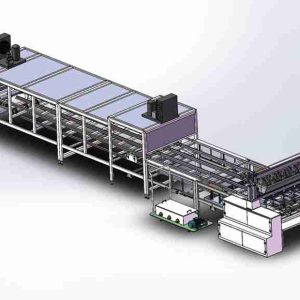

- Lifting Conveyor Capability: Equipped with a lifting conveyor for efficient candy handling.

- Double Layer Design: Allows for enhanced sugar distribution and more uniform coating.

- Two-Way Turning Mechanism: Ensures thorough sugar application from all angles.

- Oil or Wax Coating Option: Versatile for use with jelly candies, capable of oil or wax coating applications.

- Steam Sprayer Compatibility: Can be integrated with a steam sprayer for additional processing needs.

- Easy Installation & Maintenance: Designed for straightforward installation and hassle-free maintenance.

Technical Specifications:

- Material: Stainless steel 304 for corrosion resistance and easy cleaning.

- Operation Mode: Automatic with manual feed options for sugar and candies.

- Coating Options: Suitable for sugar, oil, or wax coatings, expanding the machine’s application range.

Applications:

- Ideal for gummy and jelly candies, enhancing the texture and preventing stickiness. Also suitable for chocolate and other confectionery items that require a sugar, oil, or wax coating.

Customer Support & Services:

- Professional Installation: Our team of engineers ensures precise installation and integration with your existing production line.

- Comprehensive Training: We provide detailed training for operators to ensure the machine is used safely and efficiently.

- After-Sales Service: Quick response to any maintenance or operational issues, supported by online technical assistance within 24 hours.

- Annual Maintenance Programs: Offer ongoing support to keep your machine in optimal condition.

FAQ:

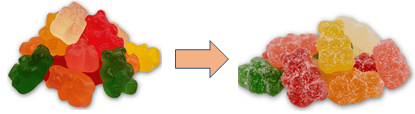

Q: What is sugar sanding? A: Sugar sanding is the process of applying a layer of sugar particles to candy to prevent stickiness and provide a specific texture and finish.

Q: Is sugar sanding done before or after candy drying? A: The sugar sanding machine can be used before or after candy drying, depending on the desired texture of the final product.

Q: Can the machine be used for oil or wax coating? A: While the machine is primarily designed for sugar coating, it can also be adapted for oil or wax coating applications with some modifications.

Q: What is the lead time for machine delivery if I order now? A: The standard lead time is 20-40 days, but it’s best to confirm the exact timing with our sales team before placing an order.

Q: How should the machine be maintained? A: We provide a detailed maintenance manual with each machine, outlining daily operations, machine descriptions, and maintenance routines.

Why Choose Us – The Manufacturer:

- Real Factory Experience: We are a genuine manufacturing facility with a proven track record in the confectionery equipment industry.

- Professionalism & Expertise: Over 40 years of machine manufacturing experience, supported by a team of designers and engineers for comprehensive technical support.

- Reliability & Quality: A modern factory with over 200 workers, strict quality control, and adherence to German manufacturing standards.

- High-Quality Machines: All machines are made in a GMP-standard factory, using SUS304 materials and sandblasting surface coating for durability.

Our Commitment to You:

- Customized Solutions: We offer factory layout planning, 3D design, project planning, customized shape design, and product formula development to meet your specific needs.

Get a Quote Now: For a personalized quote and to experience the difference that our Sugar Sanding Machine can make in your confectionery production, contact us today.

Specification

| Model | 1000 |

| Inner diameter | 890mm |

| Power | 1.1kw |

| Capacity | 300-400kg/hour |

Candy picture reference

According to your machine line, our machine could be customized, such as lifting conveyor, steam sprayer, etc.