Advantages of Effective Troubleshooting in Candy Production

Implementing effective troubleshooting techniques on a candy bar production line offers numerous advantages that enhance overall manufacturing performance and product quality.

Increased Production Efficiency

By quickly identifying and resolving issues such as equipment malfunctions or ingredient inconsistencies, manufacturers can minimize downtime and maintain a smooth production flow. This leads to higher operational efficiency and increased production capacity, allowing businesses to meet market demands more effectively.

Improved Product Quality and Consistency

Effective troubleshooting helps maintain consistent quality standards across all batches by addressing factors that cause variability, such as temperature fluctuations or improper ingredient mixing. This consistency strengthens consumer trust and satisfaction, which are vital for brand reputation and customer loyalty.

Extended Machinery Lifespan

Regular maintenance and timely resolution of equipment problems prevent excessive wear and unexpected breakdowns. Preventive maintenance, supported by troubleshooting insights, extends the machinery lifespan, reducing capital expenditures and ensuring reliable production operations.

Enhanced Food Safety and Compliance

By promptly addressing quality control failures and contamination risks, troubleshooting supports adherence to stringent food safety regulations and quality standards. This ensures product safety, minimizes recalls, and safeguards consumer health.

Cost Savings and Waste Reduction

Identifying root causes of production inefficiencies or defects reduces material waste, such as excess chocolate or spoiled batches. Efficient troubleshooting lowers repair costs and prevents costly production stoppages, contributing to overall cost savings.

Adaptability to Market Trends and Consumer Preferences

Effective troubleshooting allows manufacturers to swiftly adapt processes to incorporate functional ingredients, plant-based alternatives, or new formulations demanded by health-conscious consumers. This flexibility supports innovation and competitiveness in evolving markets.

Strengthened Workforce Competence

Ongoing staff training in troubleshooting techniques fosters a skilled workforce capable of proactive problem-solving. This reduces operator errors, improves operational efficiency, and promotes a culture of continuous improvement.

In summary, integrating comprehensive troubleshooting practices on a candy bar production line delivers significant advantages, including optimized production capacity, superior product safety, and enhanced consumer trust, all of which contribute to long-term business success.

Introduction to Candy Making

Candy making involves a complex production process that makes candy by transforming raw materials through specific techniques, requiring careful attention to detail and quality control measures to ensure consumer safety and satisfaction.

Understanding the manufacturing process and production stages is crucial for identifying and resolving issues on the candy production line.

The use of high-quality materials, such as cocoa butter and cocoa powder, is essential for maintaining product quality and meeting consumer expectations. There is a growing demand for innovative and healthier candy options, making it increasingly important to cater to health conscious consumers in candy making.

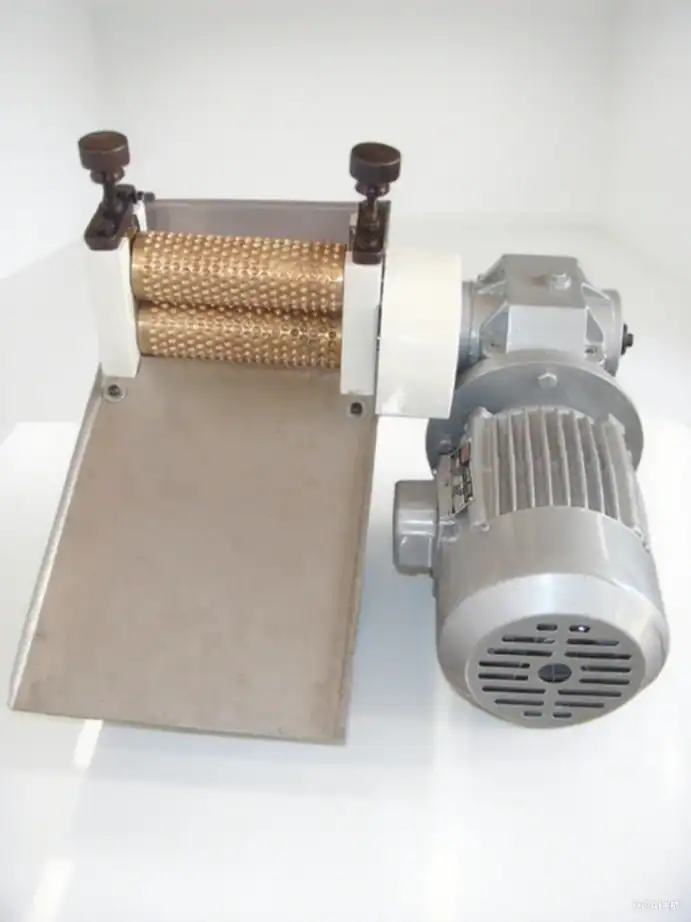

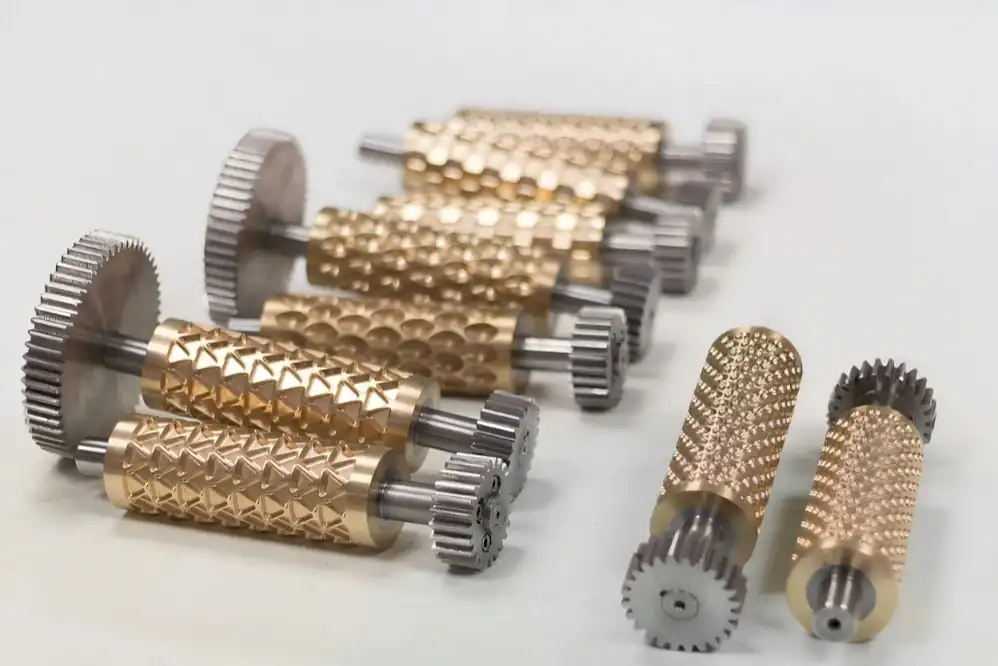

Proper lubrication and maintenance of machinery are also vital for ensuring smooth production and preventing downtime. Relying on outdated machinery can lead to increased downtime and inefficiency, highlighting the need for regular upgrades to maintain competitiveness and product quality.

Understanding Candy Production

The Science of Candy Production

- The production process involves a series of chemical reactions and physical changes that transform raw materials into a final product.

- Temperature control and heat distribution are critical factors in candy production, as they can affect the texture, consistency, and quality of the final product. Precise control of temperature, ingredient ratios, and processing times is essential to ensure uniformity and high product quality. Temperature fluctuations can lead to issues like sugar bloom and inconsistent texture.

- The use of candy molds and proper labeling are also important for ensuring that the final product meets consumer expectations and food safety regulations. Texture and consistency are key quality attributes; air bubbles can form during production, affecting the appearance and overall quality of the candy.

- Understanding the science behind candy production is essential for troubleshooting common issues and optimizing the production line. It is also important to maintain consistency in taste, texture, and appearance throughout the process.

Types of Candy Production

Hard Candy Production

- Hard candy production involves the use of sugar, corn syrup, and water to create a sugar solution that is heated to a specific temperature to produce a hard, glassy candy.

- The use of a candy thermometer is essential for ensuring that the sugar solution reaches the correct temperature and consistency.

- Proper cleaning and maintenance of equipment are also crucial for preventing contamination and ensuring consistent quality.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Kwaliteitscontrolemaatregelen

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

Optimaliseren van de productie

cURL Too many subrequests. Snoepproductielijn

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

Conclusie

- cURL Too many subrequests. candy bar production line cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.