Beyond the Beep: A Technical Analysis of Metal Detection in Candy Production Lines

Introduction: Why Metal Detection Matters in Candy Manufacturing

사탕 생산 라인에서, metal detection isn’t just a beep on the conveyor belt—it’s a core safeguard for food safety. Even the tiniest piece of stainless steel, broken blade, or loose screw can contaminate an entire batch of sweets, leading to recalls, financial loss, and damaged brand trust.

While hobbyists use detectors to find coins or jewelry, in the candy industry these machines act as the final line of defense between the factory and the consumer. Understanding how they work is crucial for quality managers, engineers, and food safety professionals.

This article goes beyond the basics. We’ll explore the physics behind metal detectors, the main detection technologies, and their specific role in modern candy production lines.

The Physics Behind Metal Detection in Food Lines

The Transmitter Coil: Creating a Magnetic Field

In candy production, products pass through a metal detector aperture. Inside, a transmitter coil generates an electromagnetic field.

-

Think of this as the “searchlight” sweeping through each chocolate bar, lollipop, or gummy pack.

Eddy Currents: The Contaminant’s Echo

When this field hits a metal contaminant—like a tiny blade fragment—eddy currents form within the particle.

-

These currents create their own secondary magnetic field, like ripples in water.

The Receiver Coil: Detecting the Disturbance

A receiver coil is finely tuned to pick up only these faint echoes, ignoring the main transmission field.

-

If metal is detected, the system instantly triggers a reject mechanism, removing the contaminated candy from the line.

This sequence—transmit, react, detect—happens in milliseconds, allowing candy factories to maintain high throughput without compromising safety.

Core Metal Detection Technologies

1. Very Low Frequency (VLF) Detection

-

Common in dry, low-moisture candies (e.g., hard candy, packaged chocolates).

-

Works by measuring phase shift between transmitted and received signals.

-

Advantage: High discrimination—can distinguish between different metal types.

-

Limitation: Sensitive to product effect (e.g., chocolate with high moisture or fillings).

2. Pulse Induction (PI) Detection

-

Preferred in challenging environments like sticky gummies or moist sugar products.

-

Sends short, powerful pulses, then measures signal decay from metal.

-

Advantage: Greater depth penetration, resistant to salt/sugar interference.

-

Limitation: Lower discrimination, mostly identifies presence/absence of metal.

Head-to-Head Comparison for Candy Factories

| 특징 | VLF Detection | Pulse Induction (PI) |

|---|---|---|

| 최적 용도 | Chocolate, dry packaged sweets | Gummy, high-sugar or moist candies |

| Discrimination | Good (metal type) | 제한적 |

| Product Effect | High sensitivity to moisture/fats | Resistant |

| Cost | Lower to medium | Medium to high |

Application in Candy Production Scenarios

🍫 Chocolate Bars & Coated Candies

-

Risk: Stainless steel fragments from machinery, foil wrapping interference.

-

해결책: High-frequency VLF systems with advanced “product effect” compensation.

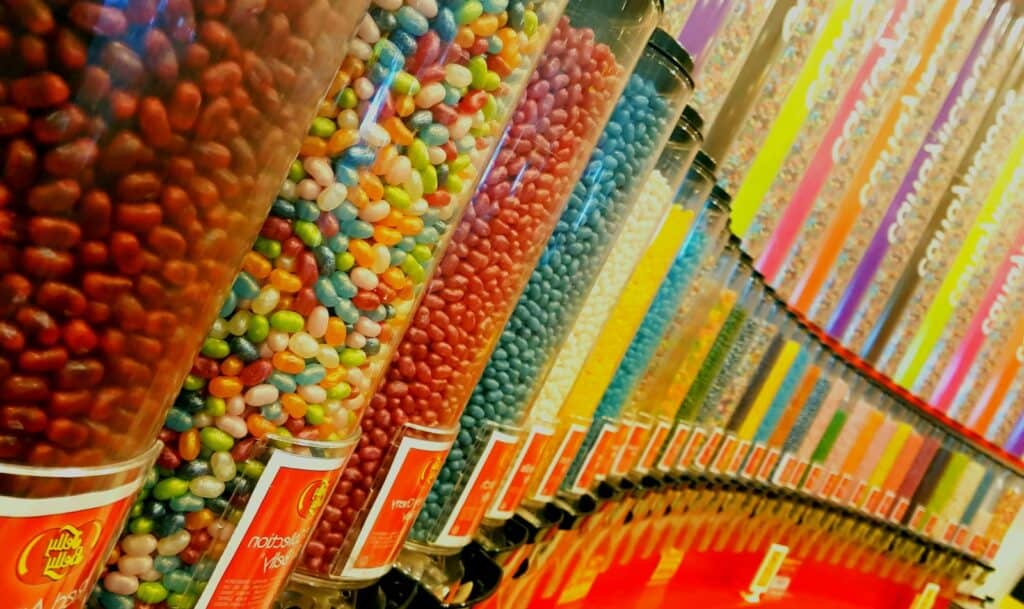

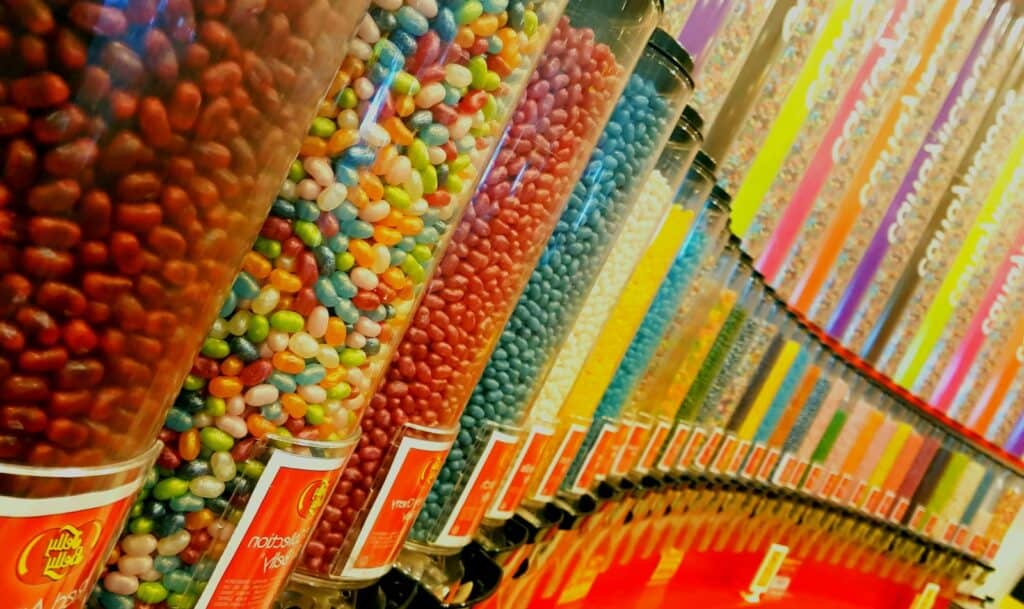

🍬 Gummy & Jelly Lines

-

Risk: Sugar stickiness + high water content = false rejects.

-

해결책: Pulse Induction detectors to reduce interference and ensure accuracy.

🍭 Hard Candy & Lollipops

-

Risk: Metal shavings from cutters and forming dies.

-

해결책: Inline detectors with automatic rejection systems at packaging stage.

The Art of Discrimination in Food Metal Detection

Discrimination in candy production is less about identifying a “coin vs. nail” (like hobby detectors) and more about distinguishing real metal contaminants vs. product interference.

-

High salt content in caramel or licorice can mimic a metallic signal.

-

Modern detectors apply algorithms to separate true contaminants from harmless conductivity effects.

Advanced Trends in Candy Production Line Metal Detection

Multi-Frequency Technology

-

Allows inspection at several frequencies simultaneously.

-

Ideal for mixed candy packs with different densities and moisture levels.

Integration with X-ray Systems

-

Many candy plants combine metal detection + X-ray inspection.

-

X-ray covers contaminants like glass, stones, dense plastic that metal detectors can’t find.

AI & Data Analytics

-

New systems use AI pattern recognition to reduce false positives.

-

Data logging helps factories comply with HACCP and FDA regulations.

Conclusion: Building Safer Candy Production with Detection Technology

Metal detectors in candy production are more than just machines that “beep.” They are precision instruments applying physics, electronics, and software intelligence to protect consumers.

By understanding VLF vs. PI, managing product effect, and integrating with X-ray and AI systems, candy manufacturers can ensure:

-

Stronger safety compliance

-

Fewer false rejects

👉 For candy producers, metal detection isn’t an afterthought—it’s the heartbeat of modern food safety.

- IEEE – Institute of Electrical and Electronics Engineers https://www.ieee.org/

- ASTM International – Security & Detection Standards https://www.astm.org/

- ISO – 국제 표준화 기구 https://www.iso.org/

- 국가 표준기술원 (NIST) https://www.nist.gov/

- FDA – U.S. Food and Drug Administration (Food Safety) https://www.fda.gov/

- SAE International – Electromagnetic Standards https://www.sae.org/

- Transportation Security Administration (TSA) https://www.tsa.gov/

- IEC – International Electrotechnical Commission https://www.iec.ch/

- ANSI – American National Standards Institute https://www.ansi.org/

- Smithsonian Institution (Archaeology & History) https://www.si.edu/