The process of making gummy bears is a delicate balance of science and precision, with temperature control playing a pivotal role in ensuring the quality, texture, and consistency of the final product. From the mixing of ingredients to the cooling and setting of the gummy mass, every stage requires strict temperature management. This article will explore how a gummy bear machine maintains optimal temperatures throughout the production process.

1. Initial Mixing Phase

The journey of creating gummy bears begins with the mixing phase, where ingredients such as sugar, gelatin, water, and flavorings are combined. The machine’s mixing tanks are equipped with built-in heating elements and temperature sensors that allow for precise heating to a specific temperature. This is crucial for the proper dissolving of gelatin and the homogenization of the mixture.

2. Homogenization

During the homogenization process, the gummy bear machine ensures that the temperature is uniform throughout the mixture. This is achieved by continuous stirring mechanisms that not only mix the ingredients but also help in maintaining a consistent temperature profile.

3. Temperature Sensors

Advanced temperature sensors are placed at various points within the mixing tanks to monitor the temperature in real-time. These sensors are connected to a control system that automatically adjusts the heating elements or initiates cooling processes to maintain the desired temperature.

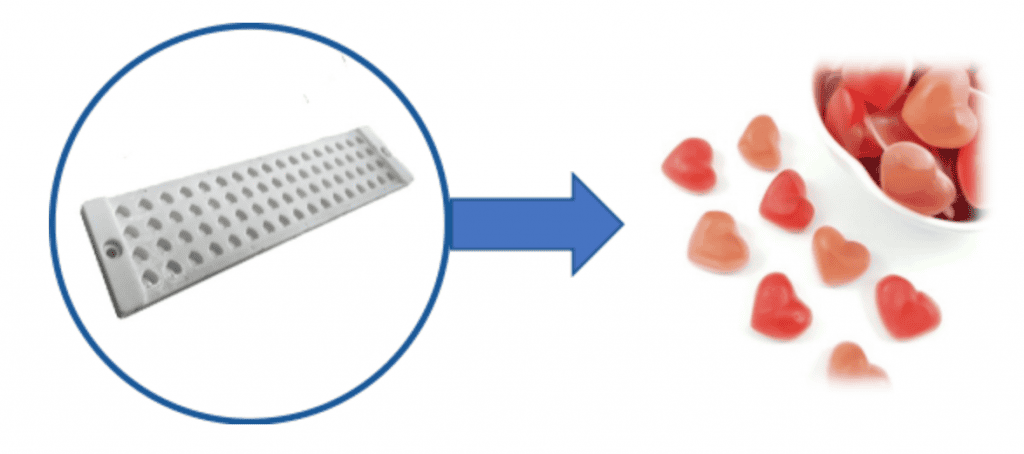

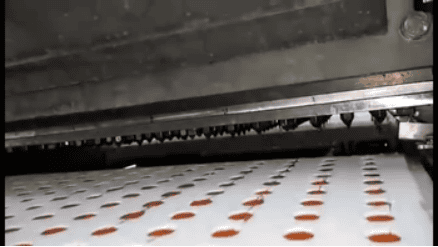

4. Cooling Tunnels

Once the gummy mass is ready, it is poured into molds and then transported through cooling tunnels. These tunnels are temperature-controlled environments that gradually reduce the temperature of the gummy mass to facilitate setting and solidification. The cooling process is carefully managed to avoid premature hardening or uneven texture.

5. Cooling Systems

Gummy bear machines are often equipped with cooling systems that can be water-based or utilize refrigerants. These systems are designed to lower the temperature of the gummy mass to the optimal range for setting. The cooling rate can be adjusted based on the specific requirements of the gummy bear recipe.

6. Temperature Gradient

In some machines, a controlled temperature gradient is created within the cooling tunnel. This gradient ensures that the gummies cool from the outside in, which helps to maintain a consistent texture and prevents the formation of condensation that can affect the gummies’ appearance.

7. Automated Control Panels

Modern gummy bear machines feature automated control panels that allow operators to set and monitor the temperature parameters for each stage of the process. These panels provide a user-friendly interface for managing the complex temperature requirements of gummy bear production.

8. Calibration and Maintenance

Regular calibration and maintenance of the temperature control systems are essential to ensure accuracy and consistency. This includes checking the temperature sensors and heating or cooling elements for any faults and making necessary adjustments.

9. Quality Control Checks

Throughout the production process, quality control checks are performed to ensure that the temperature settings are adhered to and that the gummy bears are developing the desired texture and hardness.

10. Final Cooling and Packaging

After the gummies have been formed and have undergone the initial cooling process, they are often subjected to a final cooling phase before packaging. This ensures that they are fully set and stable, maintaining their shape and texture during packaging and transportation.

Conclusion

Temperature control is a critical aspect of gummy bear production, affecting every stage from mixing to cooling. With sophisticated machinery, precise sensors, and automated systems, gummy bear machines maintain strict temperature parameters to produce gummies with consistent quality. The嚼y texture and vibrant colors of gummy bears are the result of careful temperature management, showcasing the art and science behind candy-making.