During this process, the cocoa beans are first fermented, roasted, and ground. After that, they are liquefied or melted, and then mixed with sugar. This process creates the chocolate that we all know and love. But how exactly is chocolate made? How do cocoa beans get to the chocolate bar? Let’s take a look. And remember to visit the chocolate factory to sample some delicious creations.

Cocoa beans are fermented, roasted and ground

The fermentation process is the first step in the chocolate-making process. It helps remove the viscous pulp surrounding the cocoa bean, enables drying and improves the colour of non-germinating beans, and activates hydrolytic bean enzymes. The fermentation process also helps unlock the full flavour potential of cocoa beans, a process that involves an exchange of molecules and a diffusion of enzymes between the cotyledons and the surrounding environment.

After harvesting, cacao beans are then fermented, roasted and ground in a factory. They are then blended with other ingredients, refined and ground, and blended in order to make chocolate. This process takes up to three months, and some factories may even have tens of thousands of workers! The chocolate that you taste today is not what it was originally. It has a history that stretches back more than four thousand years.

They are liquefied

After liquefying chocolate, it is poured into molds. These molds are then allowed to set and the resulting chocolate cake is bitter and unsweetened. A second step in the process is to add butter to the chocolate paste, which is then blended into the chocolate. The chocolate is then packaged and shipped. Chocolate is often shipped in a liquid state to other food manufacturers. This process is now automated and can be monitored electronically.

Before cocoa beans can be roasted, they must be cleaned and tested for defects. It must also pass a series of tests to ensure it’s free of mold and other contaminants. Before the beans are roasted, they are tested for flavor and aroma. Then, they’re placed in a current of air to remove excess nibs. The whole process can take hours or days, and the flavor of the finished product is affected by the conching process.

They are melted

There are many different types of chocolate. Each one has its own distinctive flavor, which depends on the quality of cocoa beans and the process of making it. The texture and melting time of chocolate also affect its flavor. While chocolate is the most popular sweet treat, the quality of cocoa beans is also crucial to the quality of its flavor. In the factories, cocoa beans that contain over 53% cocoa butter are ground in a machine called a cocoa grinder. The friction heating causes the cocoa butter to liquefy, forming a chocolate pulp. This pulp is then placed in a giant hydraulic press, which uses pressure to separate liquid cocoa butter from the cocoa powder.

After it has been melted, chocolate is poured into molds to make a variety of desserts and drinks. The liquid chocolate then solidifies, leaving a cake that is both bitter and unsweet. While melting chocolate in a candy factory is the most common method of chocolate making, the process is the same for other types. If you’re interested in learning more about chocolate manufacturing, you should read this article.

They are mixed with sugar

The chocolate industry has long been a business of adding sugar to produce a sweeter product, and the process for making chocolate is an ongoing process. Finished chocolate, which is made in factories, is about 50% sugar, with a portion of the sugar coming from added sugar. This sugar is usually sucrose, though it can also be lactose (for milk chocolate). In recent years, other types of sugar, such as fructose and sorbitol, have been added to chocolates. High humidity causes sugar to bloom on chocolate, which is then extracted by crystallization. Once the water is removed, the chocolate recrystallizes, releasing the sugar again.

The cacao tree is an evergreen plant that is native to the deep tropical region of the Americas. The most common genotype is found in the Amazon basin and was slowly transported throughout Central and South America by humans. In 1847, C.J. van Houten patented a process for pressing cocoa butter and fat from the bean. The process was later patented and became known as “chocolate-making.”

They are flavored with vanilla

A global company, Solvay, produces natural vanillin (a flavoring agent), which is added to chocolate in factories. It’s a complex process, which produces less than 1% of the world’s vanilla demand. Most chocolate companies, however, still use industrially produced vanilla extract. Moreover, the process requires more time and labor than harvesting and processing vanilla beans by hand. This is why many chocolate brands have chosen to use industrially produced vanilla.

The vanillin compound found in vanilla is the most common flavoring ingredient. It comprises 2.5% of the 250+ compounds found in vanilla and is produced during the aging process. These compounds are blended together to deliver the complex notes of vanilla. There are two main types of vanilla: Madagascar vanilla and synthetic vanillin. The former is more expensive than synthetic vanilla, and is used in the same applications as natural vanilla.

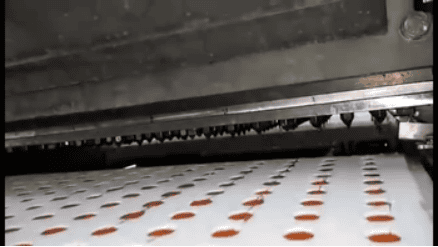

They are rolled

Rolling chocolate is an essential step in the production of quality chocolate. A machine uses a vacuum to dry the chocolate paste, and then giant rollers plow the chocolate between them to form balls. After the chocolate balls are formed, they are passed through a second machine, called a conche, which grinds the paste between heavy rollers. This process produces chocolate bars with a remarkably even texture and is a key step in the production process. Modern chocolate factories use electronic equipment and software to check the process and maintain consistent quality.

Modern chocolate is made using commodity beans. Major industrial chocolate manufacturers purchase beans in bulk and don’t care about quality. Therefore, these chocolates may contain bad beans. Large chocolate manufacturers often mix in other ingredients as well, to make up for the lack of quality. Similarly, many cheap chocolates may contain other ingredients that may be harmful to the body. Ultimately, this is how we end up with the high price of chocolate bars.