Ah, the gummy manufacturing machine – the unsung hero behind the chewy, colorful delights that have been known to make both kids and adults go “gummy-eyed” with excitement.

But have you ever wondered what happens behind the scenes, how these little treats come to life, and what the basic function of a gummy manufacturing machine is?

Strap in, and let’s embark on a sugar-coated journey through the fascinating world of gummy production.

1. The Alchemy of Ingredients

The story of every gummy starts with the ingredients, and our gummy manufacturing machine is like a master chef, mixing and matching to create the perfect concoction.

The primary ingredients include sugar, glucose syrup, water, and gelatin or pectin, which act as the gelling agents. Just like a secret family recipe, the exact proportions are the machine’s closely guarded secret.

2. A Hot Pot of Gummy Magic

Once the ingredients are ready, it’s time to heat things up. The gummy manufacturing machine has a built-in heating system that’s not just warm and fuzzy; it’s precise and efficient. It ensures the mixture reaches the optimal temperature for dissolving and blending, turning it into a smooth, gummy base. And don’t worry, it’s not so hot that it would make your gummies say, “I’m melting!”

3. Flavors and Colors – The Gummy’s Personality

After the base is ready, it’s time to give our gummies some personality. The machine carefully doses the right amount of flavors and colors. Whether it’s the tangy burst of strawberry, the zesty punch of lemon, or the deep blue of blue burry flavor (just kidding about the last one – gummy bears aren’t known for their love of coding), the machine ensures each gummy is as vibrant and tasty as the next.

4. Into the Molds They Go

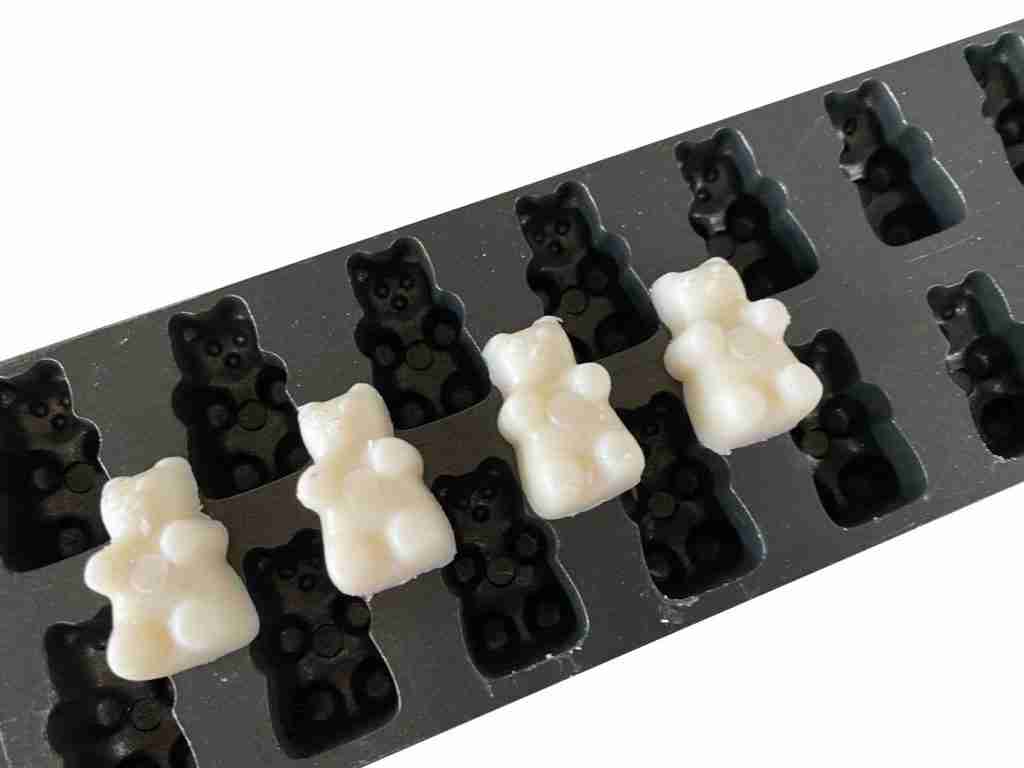

Now, picture this: a vast array of molds, each cavity waiting patiently to be filled with the gummy mixture. The gummy manufacturing machine, with its automated precision, deposits the liquid gummy base into these molds. It’s like watching a high-tech artist at work, painting with flavors instead of pigments.

5. The Grand Cooling Off

Once the molds are filled, it’s time for the gummies to set. The machine moves the molds into a cooling area, where they chill out and solidify. This is the part where the gummies go from a liquid state to the chewy, jiggly treats we all know and love. And no, they don’t gossip about the other candies while they’re chilling.

6. Ejecting the Gummies – A Well-Executed Exit

With a cool confidence, the gummies are now ready to make their exit from the molds. The machine uses a carefully calibrated system to eject the gummies without damaging their shape or, heaven forbid, losing a limb. It’s like a perfectly executed magic trick, but instead of a rabbit, you get a gummy bear!

7. A Touch of Class – The Coating Process

For some gummy candies, the journey doesn’t end with demolding. Some gummies get a touch of class with a coating of chocolate, sugar, or other toppings. The machine applies this coating with a steady hand, ensuring each gummy gets dressed to impress.

8. Quality Checks – The Gummy Auditions

Before the gummies can make their way into the world, they have to pass the audition – or in this case, the quality checks. The machine is equipped with sensors and cameras that scrutinize each gummy for size, shape, and appearance, ensuring that only the best make it to the final cut.

9. Packaging – Dressing Up for the Big Stage

The final step in our gummy’s journey is dressing up for the big stage – or the candy aisle. The machine packages the gummies in a variety of forms, from individual wraps to bulk bins, ready for eager hands to grab them.

10. The Encore – Continuous Production

And just like that, the curtain doesn’t close on our gummy show. The machine is designed for continuous production, ensuring a steady stream of gummies to satisfy the world’s sweet tooth.

Conclusion

So, there you have it – the basic function of a gummy manufacturing machine is to transform simple ingredients into the delightful, chewy candies we can’t resist. It’s a process that’s as much about science as it is about art, and the machine is the maestro conducting this sweet symphony. The next time you pop a gummy bear into your mouth, remember the high-tech wizardry that brought it to life. And don’t worry, it doesn’t bite back – unless you’re into that sort of thing.