The art of jelly candy production extends beyond flavor and texture to include a vast array of shapes and sizes that captivate consumers. Jelly candy making machines play a pivotal role in this process, offering versatility and precision in creating candies that range from simple geometric forms to complex, intricate designs.

This in-depth article explores the mechanisms and techniques by which jelly candy making machines handle the production of different shapes and sizes of candies.

1. Mold Design and Selection

At the core of candy shaping is the mold design. Jelly candy making machines use a variety of mold designs to create different shapes, from traditional round gummies and gummy bears to more elaborate forms like stars, hearts, and animal shapes. The selection of mold design is the first step in determining the final shape of the candy.

2. Mold Material

Molds can be made from various materials, including stainless steel, silicone, and sometimes plastic. Each material has its own advantages and is chosen based on factors such as durability, ease of cleaning, and detail retention for complex shapes.

3. Size Variations in Molds

Molds come in different sizes to accommodate the production of various candy sizes, from mini candies for bulk packaging to large, single-piece treats. Jelly candy making machines must be compatible with the selected mold size to ensure proper filling and forming.

4. Precision Dispensing

Jelly candy making machines are equipped with precision dispensing systems that accurately control the amount of jelly mixture deposited into each mold cavity. This ensures that candies maintain consistent size and shape, regardless of the mold’s complexity.

5. Multi-Cavity Molds

For high-volume production, jelly candy machines use multi-cavity molds. These molds have multiple cavities, each forming an individual candy. The machine must evenly distribute the jelly mixture across all cavities to produce uniformly shaped candies.

6. Single-Cavity Focus

For larger or more intricate shapes, single-cavity molds may be used. Jelly candy making machines can be adjusted to focus on a single mold cavity, allowing for the production of detailed, large-sized candies.

7. Automated Mold Filling

Advanced machines employ automated systems for mold filling, which use computer-controlled pistons or pumps to inject the jelly mixture into the molds. This process ensures that each cavity is filled to the optimal level for the desired candy shape.

8. Pressure and Vacuum Systems

Some machines utilize pressure or vacuum systems to assist in the mold filling process. These systems can help in removing air bubbles from the jelly mixture, ensuring a smooth and clear final product.

9. Cooling and Setting

After filling, the molds are cooled to set the shape of the candies. Jelly candy making machines control the cooling process to ensure that the candies solidify uniformly and maintain their shape.

10. Demolding Process

Once the candies have set, they are released from the molds. The machine’s demolding process must be carefully calibrated to handle different shapes and sizes without damaging the candies.

11. Ejector Mechanisms

Ejector mechanisms in jelly candy making machines are designed to gently push the candies out of the molds without affecting their shape or texture.

12. Shape-Specific Adjustments

Machines may require adjustments or specific settings for different shapes, such as altering the jelly mixture consistency, adjusting the filling pressure, or modifying the cooling time.

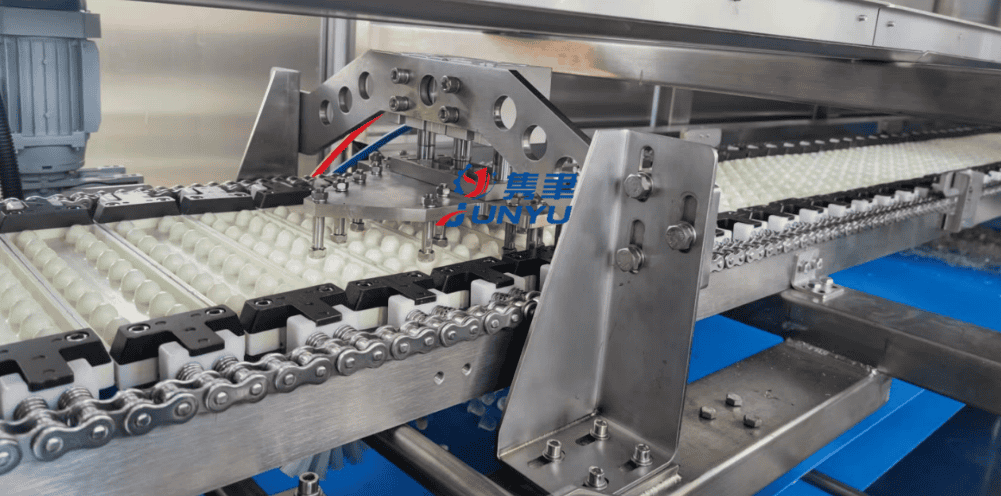

13. Continuous Motion Machines

Continuous motion machines produce candies in a continuous process, with molds on a conveyor belt that moves through different stages of the production line, from filling to cooling and demolding.

14. Batch Processing Machines

Batch processing machines, on the other hand, produce candies in batches, allowing for greater flexibility in producing different shapes and sizes within the same machine.

15. Custom Molds and Machines

For specialized shapes or sizes, custom molds and machines may be required. These are designed to meet the specific needs of the candy manufacturer.

16. Quality Control

Quality control is essential in ensuring that candies of different shapes and sizes meet the desired standards. Jelly candy making machines may incorporate sensors and cameras to monitor the shape and size of the candies during production.

17. Size and Shape Variations in Production

Some machines are capable of producing a variety of shapes and sizes in a single production run, offering flexibility in product offerings.

18. Scaling Up or Down

Adjusting the production scale for different shapes and sizes is possible with many jelly candy making machines, allowing manufacturers to respond to market demands or seasonal trends.

19. Technological Advancements

Technological advancements in jelly candy making machines, such as 3D printing for molds and computer-aided design (CAD) for mold creation, are expanding the possibilities for candy shapes and sizes.

20. Training and Expertise

Operating jelly candy making machines to handle different shapes and sizes effectively requires training and expertise. Machine operators must understand how to adjust machine settings and troubleshoot any issues that arise during production.

Conclusion

Jelly candy making machines are versatile tools that can accommodate a wide range of candy shapes and sizes, from the simplest to the most complex designs. By understanding the capabilities and mechanisms of these machines, manufacturers can produce a diverse array of jelly candies that cater to various consumer preferences and market demands. As technology continues to evolve, so too will the possibilities for candy shapes and sizes, offering endless opportunities for creativity and innovation in the confectionery industry.