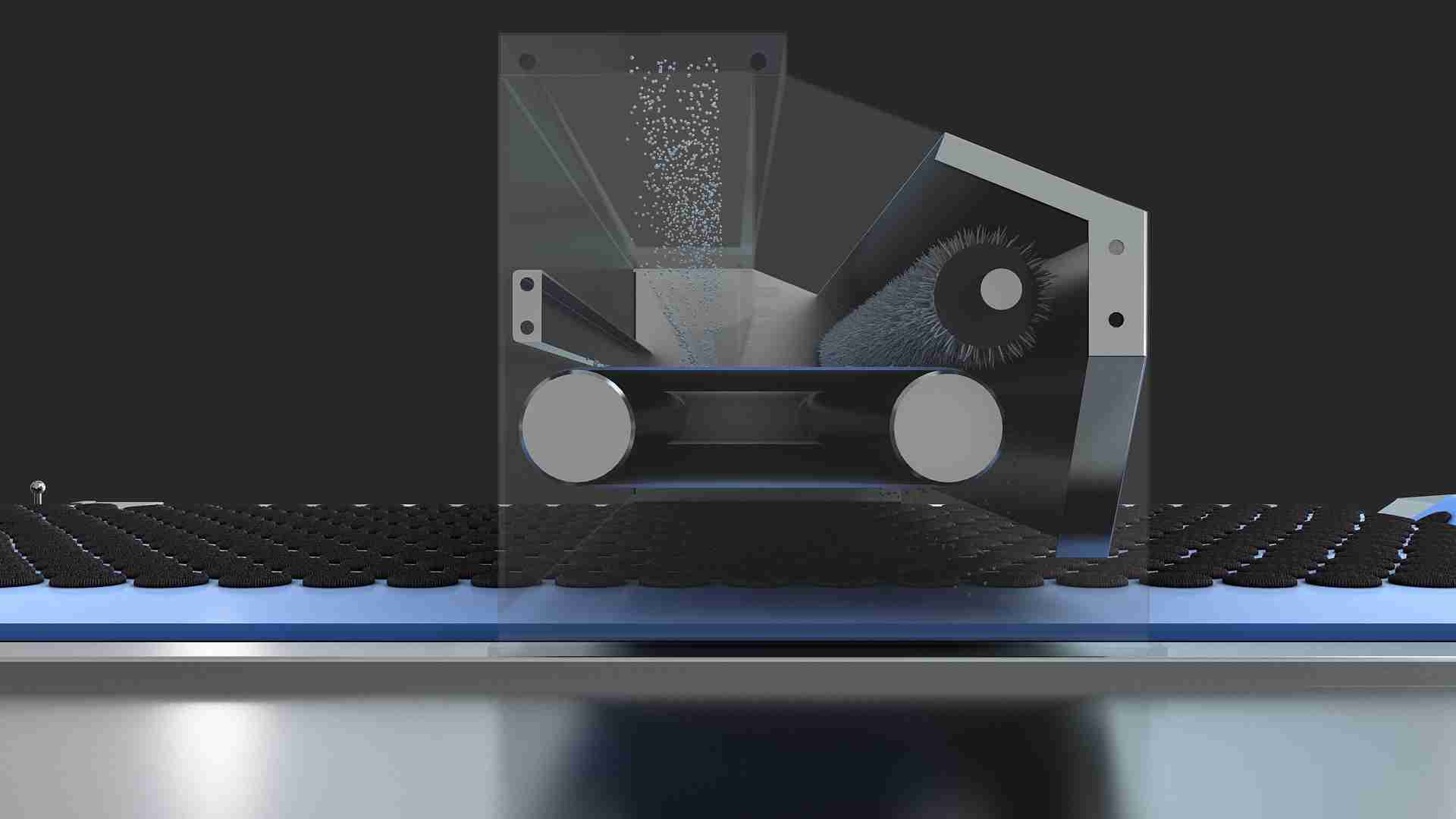

Le biscuit Marie est ce que nous appelons généralement des biscuits à pâte dure, dans lesquels la plupart de la pâte dure doit être fermentée. Junyu conseille donc le laminage et 3-4sets de machines à feuilles à rouleaux et de machines de coupe à rouleaux pour fabriquer des produits topiques à pâte dure avec un goût croustillant, une surface lisse et une section transversale en couches. tels que Marie, crackers, finger biscuits et biscuits soda : Après avoir traversé la machine de laminage (en option), l'alimentateur à trois rouleaux et les trois paires de machines à aplatir les rouleaux, la pâte est découpée en différentes formes par le rouleau de moulage. La pâte restante passe par le séparateur de pâte et retourne au premier alimentateur. Le biscuit cru passe à l'équipement suivant pour être cuit.

| Modèle | JYB-280 | JYB-400 | JYB-600 | JYB-800 | JYB-1000 | JYB-1200 | JYB-1500 | Remarque |

| Capacité de production (kg/h) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | Capacité personnalisée |

| Longueur du four (m) | 16 | 28 | 40 | 40 | 60 | 50 | 70 | Dépendance |

| Longueur totale (m) | 29.6 | 64.5 | 85.5 | 92.5 | 125 | 125 | 150 | Si aucun U Turn Conveyor |

| Température de cuisson (C) | 190-240℃ | 190-240C | 190-240C | 190-240℃ | 190-240℃ | 190-240℃ | 190-240C | Dépendance |

| Puissance totale de la ligne (kW) | 80 | 90 | 300 | 400 | 00 | 800 | 900 | Si vous utilisez un four électrique |

| Four GPL (kg/h) | 10 | 20 | 35 | 45 | 60 | 70 | 80 | Si vous utilisez un four à GPL |

| Poids de la ligne entière (kg) | 6000 | 12000 | 20000 | 28000 | 35000 | 45000 | 55000 | Approximativement |

La ligne de production de biscuits Mary's entièrement automatique convient à un large éventail de scénarios de production de biscuits. Elle peut être utilisée pour produire différents types de biscuits, des biscuits Mary's traditionnels aux produits plus spécialisés et innovants. Qu'il s'agisse d'installations de fabrication à grande échelle ou d'unités de production plus petites, cette ligne offre une solution polyvalente et efficace pour répondre à divers besoins de production.

En résumé, la ligne de production de biscuits Mary's entièrement automatique est un excellent choix pour les entreprises de l'industrie alimentaire. Avec son contrôle de haute précision, ses capacités de production polyvalentes, son fonctionnement économe en énergie, son interface conviviale, ses normes d'hygiène supérieures, sa production personnalisable et sa conception rentable, elle constitue une solution efficace et fiable pour la production de biscuits de haute qualité.

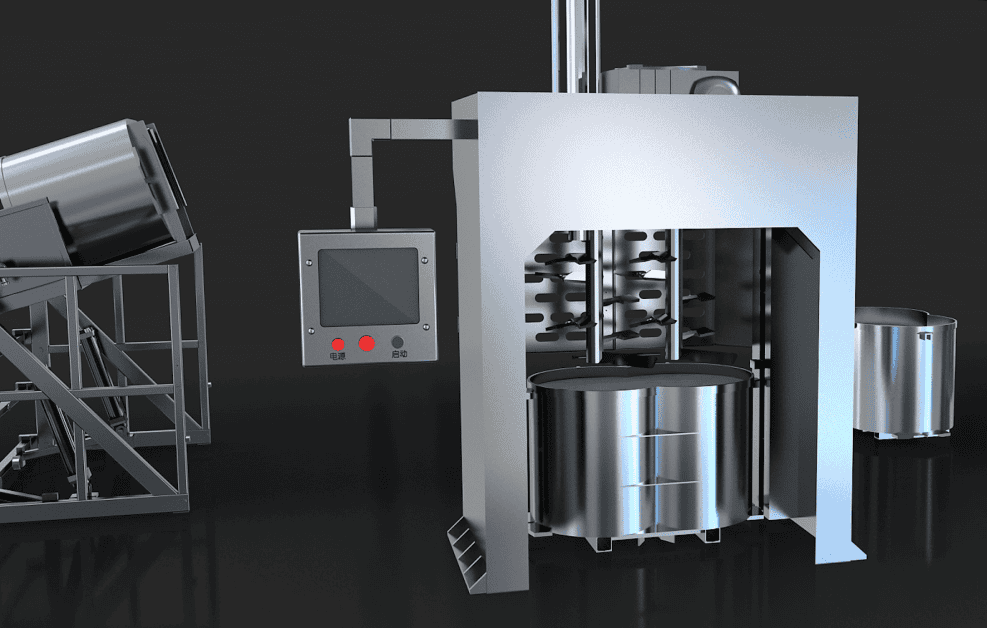

Le processus commence par l'utilisation d'un pétrin à haut rendement. Il mélange uniformément la farine, le sucre, les matières grasses et d'autres ingrédients pour former une pâte homogène, jetant ainsi les bases de biscuits de haute qualité.

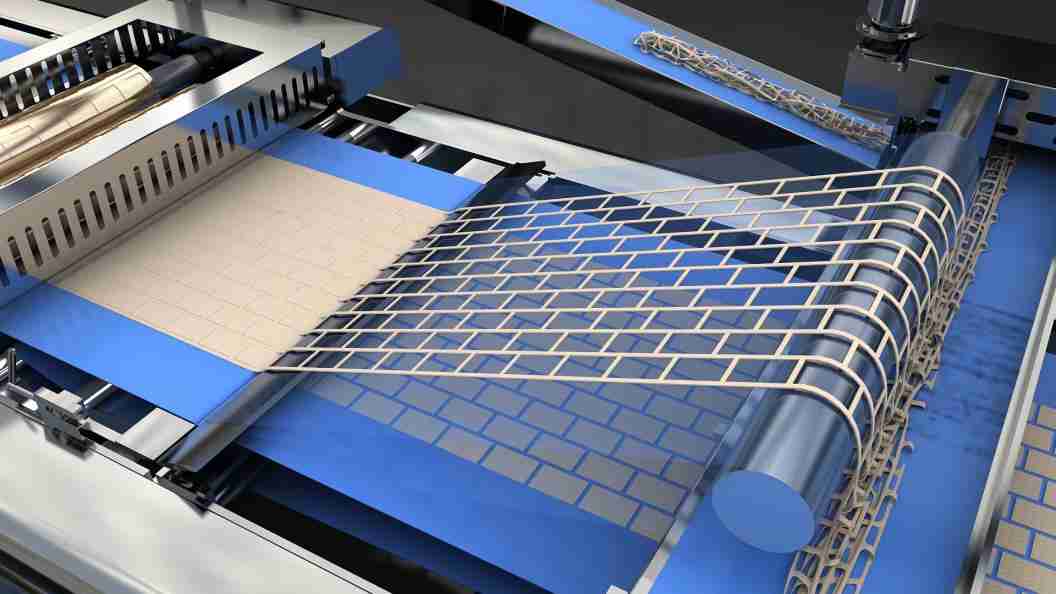

La pâte est ensuite passée dans un laminoir, qui la roule en fines feuilles d'épaisseur uniforme. Cela permet de garantir que chaque biscuit aura une texture et une forme homogènes.

Le cutter rotatif découpe la pâte dans les formes souhaitées. Grâce à ses paramètres de coupe réglables, il garantit des bords nets et un gaspillage minimal de la pâte.

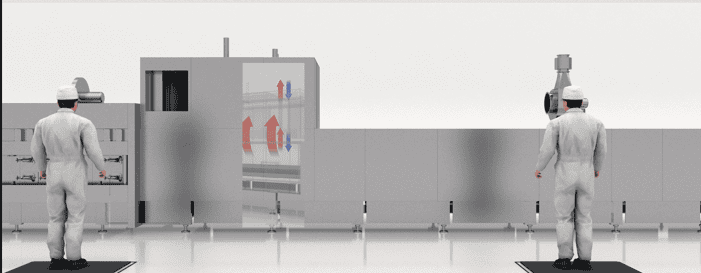

Les pâtons formés entrent dans un four tunnel pour la cuisson. Le four offre de multiples options de chauffage, y compris l'électricité et le gaz naturel, et dispose d'un contrôle précis de la température pour garantir une cuisson homogène.

Une machine à saupoudrer le sel et le sucre applique uniformément le sel et le sucre sur les pâtons, rehaussant ainsi la saveur et apportant une touche finale avant la cuisson.

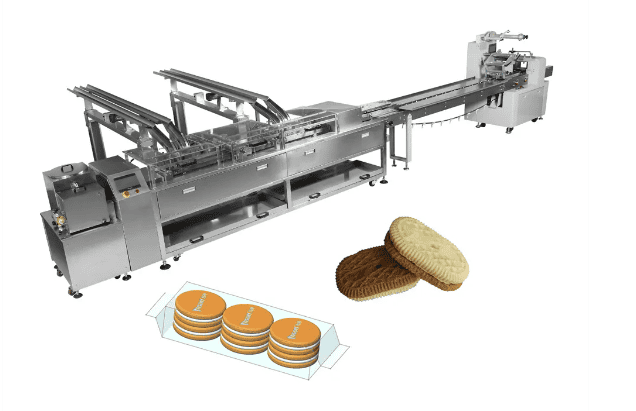

Après refroidissement, les biscuits sont empilés efficacement par une machine spécialisée, ce qui les prépare au processus d'emballage.

Pour les biscuits Mary's fourrés à la crème, une machine à sandwicher la crème remplit la crème entre deux couches de biscuits, créant ainsi de délicieux biscuits sandwichs avec une application précise de la crème.

Enfin, les biscuits sont emballés à l'aide d'un système d'emballage automatisé. Les biscuits sont ainsi parfaitement scellés et protégés pour la distribution et la vente.

Équipée d'un système de contrôle PLC et d'une interface à écran tactile, la ligne de production permet un contrôle précis de chaque étape du processus. Les paramètres tels que la température, la durée et la vitesse de dépôt peuvent être facilement ajustés pour répondre à des exigences de production spécifiques.

La ligne peut produire une grande variété de biscuits, y compris les biscuits韧性 et酥性. En changeant simplement les moules et en ajustant les formules de production, elle peut créer différentes formes et saveurs de biscuits pour répondre aux demandes du marché.

Conçue dans un souci d'efficacité énergétique, la ligne de production permet de réduire les coûts d'exploitation. Le four tunnel, en particulier, est disponible en modèles chauffés à l'électricité ou au gaz, offrant ainsi flexibilité et rentabilité.

La ligne de production est dotée d'un système de contrôle intuitif facile à utiliser. Grâce à des instructions claires et à des processus automatisés, les opérateurs peuvent rapidement devenir compétents.

Construit en acier inoxydable de haute qualité, l'équipement répond aux normes d'hygiène alimentaire. Sa conception facilite le nettoyage et l'entretien, garantissant ainsi la sécurité et la qualité des biscuits.

Disponible en plusieurs modèles avec différentes capacités de production, la ligne peut être adaptée aux besoins spécifiques des entreprises de toutes tailles.

Si l'investissement initial peut sembler important, l'efficacité opérationnelle à long terme et les faibles coûts de maintenance de la ligne en font un choix rentable pour la production de biscuits.