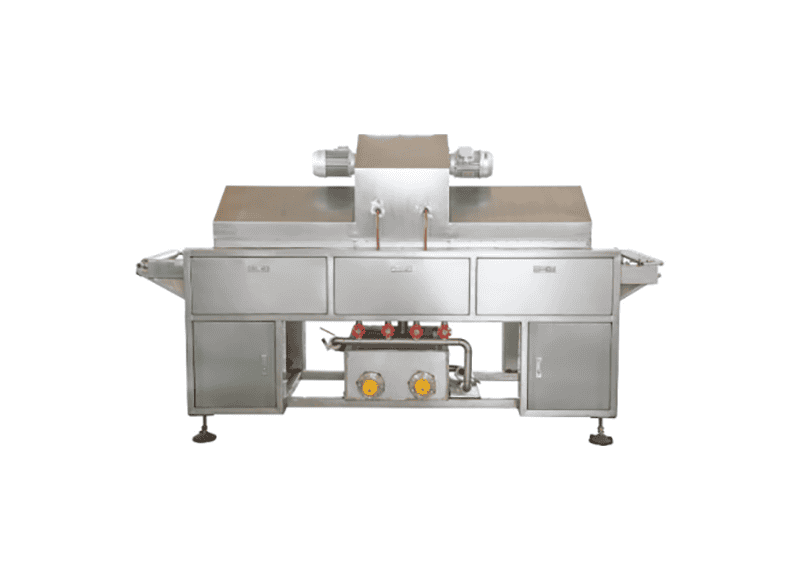

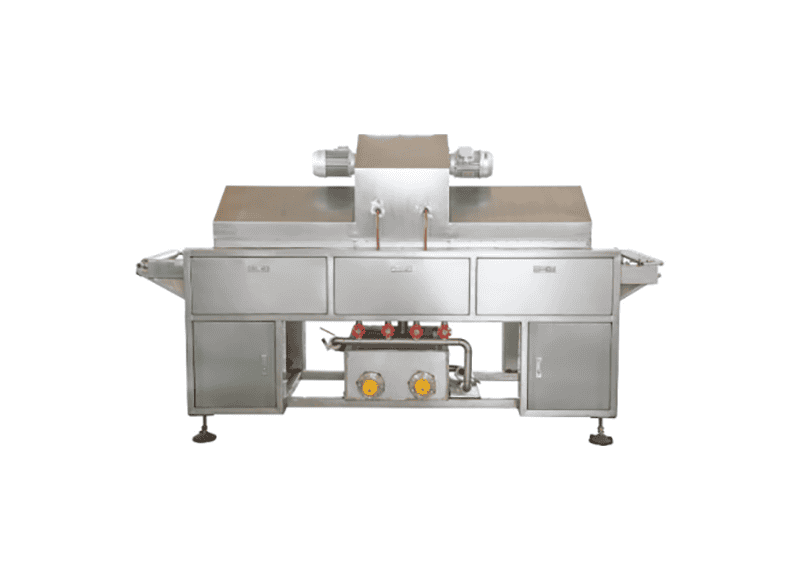

Nozzle type for small production (100-600kg/hour capacity)

Oil Spray Machine: The Versatile Solution for Uniform Coating in Biscuit Production

Product Overview: The Oil Spray Machine is an indispensable piece of equipment for the biscuit and food processing industry, designed to apply a fine mist of oil uniformly over products. This machine is perfect for both small-scale production needs, with a capacity ranging from 100-600kg/hour, and for various types of biscuits, enhancing their texture and flavor.

Key Features & Benefits:

- Multi-Application Suitability: Ideal for a wide range of applications, suitable for both hard and soft biscuit production.

- Space-Efficiency: Compact design saves valuable production space while maintaining high output.

- Easy Maintenance: The machine is easy to open, facilitating cleaning and maintenance to ensure consistent performance.

- High-Quality Materials: Constructed with SUS304 stainless steel for the mesh belt, side board, and recovery plate, ensuring durability and hygiene.

- Adjustable Oil Temperature: Allows for precise control over oil temperature to suit different biscuit types and desired outcomes.

- Reliable Components: Equipped with electric parts and operational components from renowned brands for dependable performance.

Thông số kỹ thuật:

- Capacity: Designed to handle small production volumes efficiently, from 100-600kg/hour.

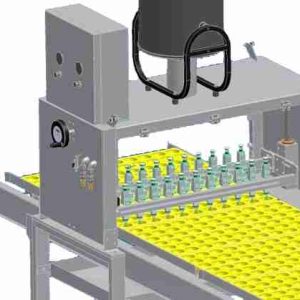

- Nozzle Type: Specifically designed for small production, ensuring even oil distribution.

- Material: SUS304 stainless steel for all contact parts, complying with food safety standards.

- Oil Temperature Control: Features an adjustable thermostat for precise temperature management.

Applications:

- Perfect for bakeries and food manufacturers producing a variety of biscuits, enhancing their texture and appearance with a fine oil coating.

Customer Support & Services:

- Professional Consultation: Our team of experts will assist you in selecting the right oil spray machine configuration for your production needs.

- Installation and Training: We provide comprehensive installation services and operator training to ensure the machine is used effectively.

- After-Sales Service: Dedicated support for maintenance and troubleshooting to minimize downtime.

FAQ:

Q: What types of biscuits can the oil spray machine handle? A: The machine is versatile and can handle both hard and soft biscuit applications.

Q: How does the oil spray machine save space? A: With its compact design, the machine is space-efficient, making it suitable for facilities with limited production space.

Q: How easy is it to clean and maintain the oil spray machine? A: The machine is designed to be easily opened for cleaning and maintenance, reducing downtime and ensuring hygiene.

Q: What material is used for the construction of the oil spray machine? A: SUS304 stainless steel is used for the mesh belt, side board, and recovery plate, ensuring durability and ease of cleaning.

Q: Can I adjust the oil temperature in the oil spray machine? A: Yes, the oil temperature is adjustable, allowing you to optimize the process for different biscuit types.

Q: Which brand components are used in the oil spray machine? A: The machine adopts components from famous brands for electric parts and operation parts, ensuring reliability and performance.

Why Choose Our Oil Spray Machine:

- Versatility: Suitable for a wide range of biscuit types and production needs.

- Quality & Durability: Constructed with high-quality materials for long-lasting performance.

- Customization & Flexibility: Designed to accommodate various production scales and requirements.

- Professional Support: Backed by a team of professionals with extensive experience in biscuit processing equipment.

Get a Quote Now: For personalized pricing and to learn more about how our Oil Spray Machine can enhance your biscuit production process, contact us today.

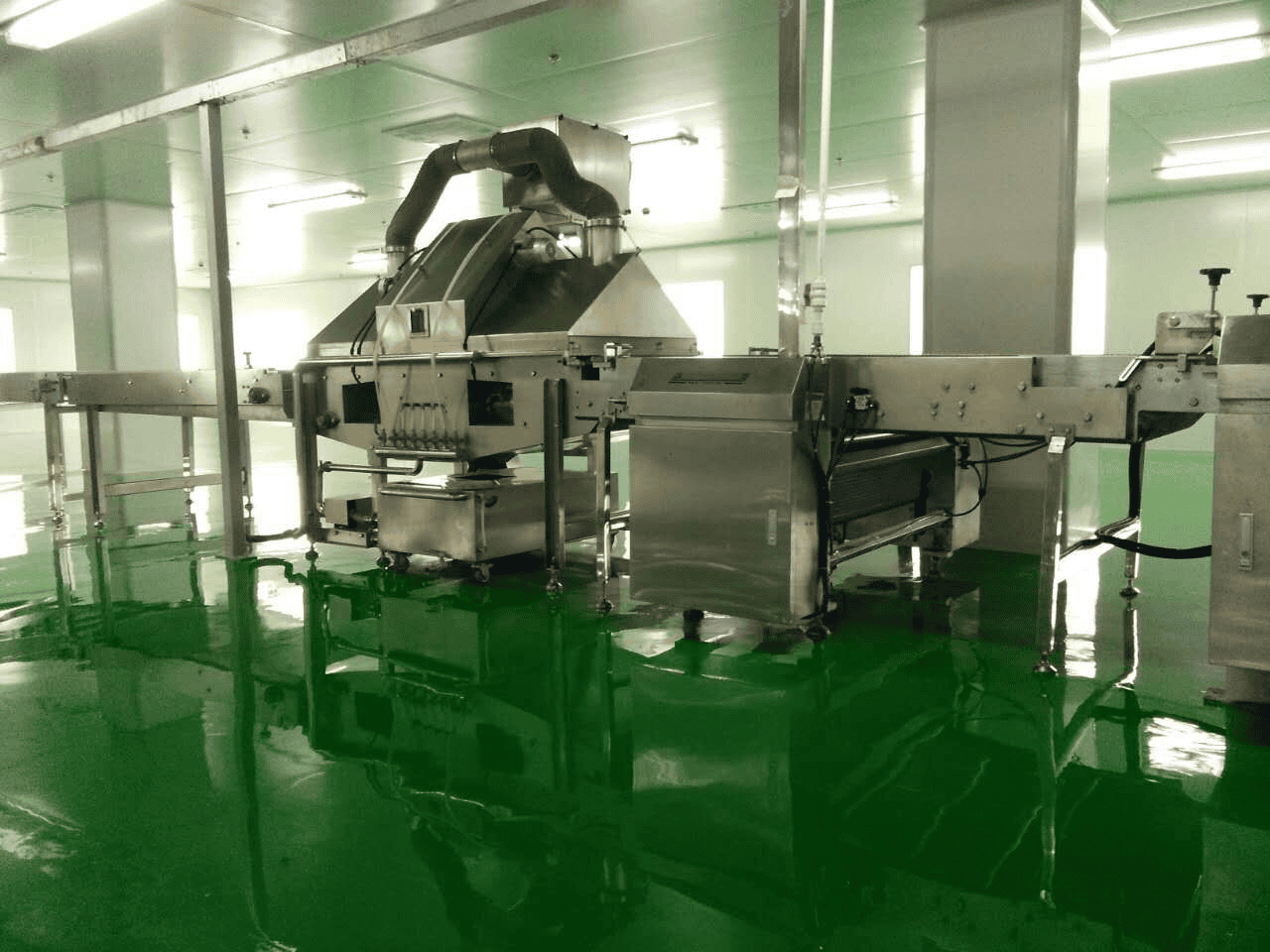

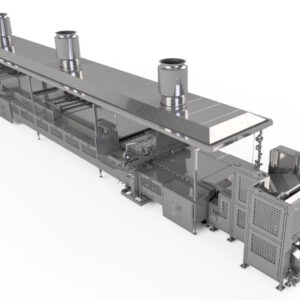

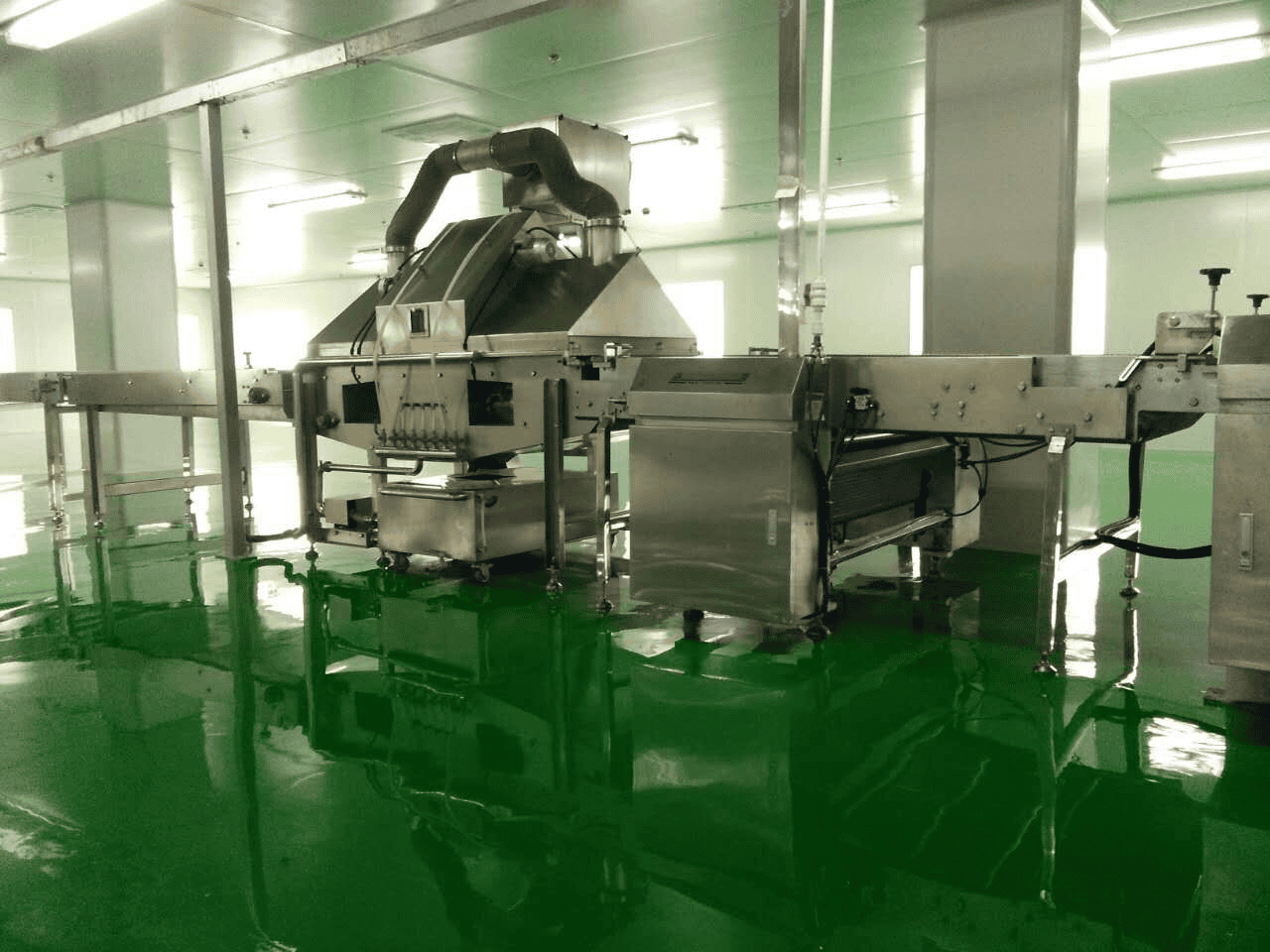

Centrifugal disc-type for big production (700-1500kg/hour capacity)

Advantage

• High-speed dish collecting the excessive oil

• Connecting with separate oil dripping conveyor

• 3-layers for oil filtering

• Invert speed control

• Oil storage tank adopts the heat insulation jacket water tank

• Equipment with the British brand oil mist collector

• High efficiency and less oil consumption

• Set with many observation windows to see the spraying effect

| Model |

JYB-280 |

JYB-400 |

JYB-600 |

JYB-800 |

JYB-1000 |

JYB-1200 |

JYB-1500 |

| Belt width |

320mm |

430mm |

630mm |

830mm |

1080mm |

1280mm |

1580mm |

| Power |

5.25kw |

5.85kw |

5.85kw |

11kw |

18kw |

22kw |

24kw |

| Size(mm) |

1200×710×1115 |

2200×1000×1255 |

2200×1200×1255 |

2300×1400×1700 |

5000x1950x2460 |

5000x2150x2460 |

5000x2450x2460 |

| Weight |

200kg |

350kg |

500kg |

600kg |

2500kg |

2600kg |

2800kg |