Я видел, как линия по производству тортов может быстро изменить мою пекарню. Теперь мое оборудование работает в более разумный способ. Ему не нужно работать больше. Это помогает мне экономить энергия и деньги сразу же. Каждый раз мои торты получаются идеальными. Система использует передовые средства контроля для поддержания высокого качества. Я больше не беспокоюсь об узких местах или потере времени. Я могу легко предлагать больше видов тортов. Я могу работать с большими заказами без лишнего напряжения. Мониторинг в режиме реального времени показывает мне, что происходит на моей кухне. Это обновление помогает моему бизнесу развиваться быстрее, чем раньше.

Основные выводы

-

А линия по производству тортов помогает пекарням быстрее готовить больше тортов. Это также помогает сократить количество отходов. Автоматизация позволяет всегда поддерживать одинаковое качество тортов. Она также помогает избежать ошибок, совершаемых людьми. Использование производственной линии позволяет пекарням меньше тратить на работников. Сотрудники могут уделять больше времени творческой работе. Умное оборудование помогает экономить деньги за счет использования меньшего количества ингредиентов. Оно также потребляет меньше энергии. Система позволяет легко готовить различные виды тортов. Это помогает привлечь больше клиентов. Правильное планирование и обучение помогают хорошо настроить систему. Они также помогают команде чувствовать себя готовой к работе. Модульные системы позволяют пекарням начинать с малого и развиваться дальше. Вначале не нужно тратить много средств. Регулярные проверки и обновления позволяют поддерживать линию в рабочем состоянии. Это гарантирует, что она останется быстрой и надежной.

Линия по производству тортов Преимущества

Выход

Когда я перешел на линия по производству тортов, В одночасье производительность моей пекарни изменилась. Мне больше не нужно было полагаться на медленное ручное смешивание или беспокоиться об узких местах. Моя новая система может производить более 400 фунтов торта в час. Это огромный скачок по сравнению с тем, что я мог сделать вручную. Автоматизация обеспечивает бесперебойную работу. Я не трачу время на очистку или перенастройку оборудования. Автоматическая система очистки экономит мне часы каждую неделю. Я вижу меньше ошибок и меньше простоев. Теперь моя пекарня легко справляется с большими заказами.

-

Мои торты получаются быстрее и свежее.

-

Я могу выполнять больше заказов клиентов, не нанимая дополнительных сотрудников.

-

Закрытая система предохраняет мои торты от загрязнения.

Совет: Если вы хотите развивать свой бизнес, линия по производству тортов обеспечит вам необходимую скорость и надежность.

Качественный

Я забочусь о каждом торте, который выходит из моей пекарни. Постоянное качество важно для меня и моих клиентов. Сайт линия по производству тортов использует депо из нержавеющей стали каждый раз идеально порционирует тесто. Мои торты пропекаются равномерно и выглядят красиво. Перекачивающие насосы плавно перемещают тесто и крем, поэтому ничего не пропадает зря и не смешивается неправильно. С помощью машин для нарезки тортов я нарезаю идеальные слои. Системы распыления сиропа сохраняют влажность и вкус каждого слоя.

Я контролирую время замеса, температура и консистенция теста нажатием одной кнопки. Благодаря этому мои торты всегда имеют нужную крошку и объем. Я не беспокоюсь о недомешивании или перемешивании. Автоматические системы контроля следят за тем, чтобы каждая партия соответствовала моим стандартам. Мои клиенты замечают разницу. Они возвращаются, потому что уверены, что мои торты всегда будут вкусными.

-

Детали из нержавеющей стали обеспечивают чистоту и безопасность.

-

Удобные элементы управления помогают моей команде работать лучше и быстрее.

Труд

До обновления моя команда тратила часы на выполнение повторяющихся задач. Теперь линия по производству тортов делает всю тяжелую работу. Мои сотрудники могут сосредоточиться на оформлении, упаковке и обслуживании клиентов. Мне не нужно столько людей на этаже, что позволяет экономить деньги. Обучать новых сотрудников стало проще, потому что система проста в использовании. Сайт модульная конструкция позволяет добавлять или менять части по мере развития бизнеса.

-

Автоматизация снижает затраты на оплату труда.

-

Моя команда испытывает меньше стресса и работает более продуктивно.

-

Я могу быстро адаптироваться к новым продуктам или большим заказам.

Примечание: Инвестиции в линию по производству тортов означают, что я делаю больше, затрачивая меньше усилий. Моя пекарня работает более гладко, а моя команда - более счастливо.

Расходы

Я всегда стараюсь экономить на своей пекарне. Когда я получил линия по производству тортов, Но мои расходы быстро сократились. Система делает все, начиная от смешивание для самостоятельной упаковки. Моя команда не тратит много времени на скучную работу. Мне не приходится нанимать столько рабочих, поэтому я экономлю деньги. Машины смешивают, формируют, выпекают, охлаждают и упаковывают торты. Благодаря этому меньше ошибок и отходов.

Я увидела, что трачу меньше ингредиентов. Регуляторы отмеряют все точно. Я не выбрасываю тесто или коржи из-за ошибок. Каждый раз мои торты получаются правильными. Система поддерживает чистоту, поэтому я не теряю торты из-за порчи. Я также экономлю электроэнергию, потому что машины потребляют меньше энергии. Моя пекарня может выполнять больше заказов, не тратя больше денег.

Совет: если вы хотите, чтобы ваша пекарня приносила больше денег, линия по производству тортов поможет вам сэкономить и заработать больше.

Разнообразие

Мне нравится угощать своих клиентов новыми лакомствами. С моей линией по производству тортов я могу делать много тортов и кексов. Машины позволяют мне контролировать каждый шаг, Так что я могу создавать разные формы, размеры и вкусы. Я использую специальные дозаторы и инжекторы, чтобы добавить начинку или крутой дизайн. Мои инструменты для декорирования помогают мне стильно завершить каждый торт.

-

Я умею печь классические торты, кексы с начинкой, мраморные торты и кексы.

-

Система позволяет быстро менять рецепты.

-

Я могу украсить его вихрями, посыпками или нестандартными узорами.

-

Моя туннельная печь и спиральный охладитель подходят для всех тортов и кексов.

-

Роботы-штабелеры помогают мне упаковывать и сортировать большие партии.

Мои клиенты видят весь выбор. Они возвращаются, чтобы попробовать что-то новое каждую неделю. Я могу выполнять большие заказы для вечеринок и мероприятий. Моя пекарня особенная, потому что я предлагаю больше выбора, чем раньше.

Примечание: Если вы хотите добавить больше товаров и привлечь больше клиентов, линия по производству тортов позволит вам сделать практически любой торт или кекс, который вы захотите.

Выбор Линия по производству тортов

Требуется

Когда я захотел приобрести линию по производству тортов, я задал себе несколько важных вопросов. Мне нужно было знать, сколько тортов я буду делать каждый день. Я подумала о том, какие торты больше всего нравятся моим клиентам. Моя пекарня не очень большая, поэтому я измерила пространство, чтобы понять, что туда поместится. Я также четко определила для себя цели. Хотела ли я быстро развиваться или просто облегчить себе работу? Эти вопросы помогли мне выбрать правильную систему.

Вот что я проверил, прежде чем выбрать систему:

-

Размер и форма моей пекарни

-

Сколько пирожных я хочу испечь в день.

-

Какие виды тортов, кексов или капкейков я хочу продавать

-

Сколько денег я могу потратить на новые машины

Совет: перед покупкой запишите свои цели и потребности. Это поможет вам найти лучшую систему для вашей пекарни.

Характеристики

Я узнал, что линии по производству жмыха не все одинаковы. В одних больше автоматизации, другие лучше подходят для приготовления различных тортов или поддержания чистоты. Мне нужна была система, которая могла бы выполнять множество задач и обеспечивать сохранность моих тортов. Мне понравилось сравнивать функции друг с другом.

|

Категория характеристики |

Основные характеристики |

|---|---|

|

Автоматизация |

Высокая степень автоматизации процессов при минимальном количестве ручного труда; точный контроль времени, температуры и скорости; работает постоянно с переключением скоростей; использует свет, электричество, газ и машины для полной автоматизации от начала до конца. |

|

Гигиена |

Сильные системы очистки и дезинфекции; использование безопасных для пищевых продуктов материалов; легкость мытья и поддержания чистоты; защита работников и тортов; упаковка сохраняет торты чистыми и сухими. |

|

Гибкость |

Возможность изготовления тортов различных типов и размеров путем изменения форм и настроек; возможность одновременного изготовления нескольких продуктов; быстрая адаптация к новым потребностям рынка; возможность замены аппликаторов для различных тортов. |

Я выбрал линию с легко моющимися деталями и защитными приспособлениями. Система позволяет мне быстро менять рецепты. Я могу готовить разные торты, меняя формы или настройки. Я не беспокоюсь о безопасности продуктов, потому что в машине используются безопасные для пищевых продуктов материалы и есть надежные системы очистки.

Поставщики

Выбор правильного поставщика был очень важен для меня. Я просмотрел множество компаний, прежде чем выбрал одну. У одних были большие машины для крупных пекарен. У других были системы поменьше, которые помещались в небольших помещениях и позволяли мне впоследствии добавлять новые детали. Мне нужны были поставщики, которые предоставляли хорошие обучение и поддержка.

Вот что я проверил, когда искал поставщиков:

-

Сколько машина может производить и насколько стабильно она работает

-

Сколько автоматики и специальных функций в нем было

-

Насколько просто было использовать и изучать его моей команде

-

Какую заботу и помощь оказала компания

-

Если бы я мог менять или добавлять детали к машине

-

Соответствует ли машина целям моего бизнеса

Примечание: Узнайте у каждого поставщика об обучении, поддержке и о том, насколько легко починить или модернизировать машину. Правильно выбранная компания поможет вашей пекарне расти и преуспевать.

Внедрение линии по производству тортов

Планирование

Я всегда начинаю с надёжный план прежде чем вводить в пекарню новое оборудование. Планирование помогает мне избежать ошибок и обеспечивает бесперебойную работу моего бизнеса. Когда я решил добавить линию по производству тортов, я выполнил следующие шаги:

-

Я работала с отделом продаж, чтобы спрогнозировать, сколько тортов мне нужно делать каждую неделю.

-

Я проверил свои запасы ингредиентов и убедился, что у меня прочные отношения с поставщиками.

-

Я создал систему, чтобы отслеживать свои запасы и не допускать отсутствия ключевых ингредиентов.

-

Я создал график производства, который соответствовал моим заказам и срокам поставки.

-

Я просмотрел свой планировка пекарни чтобы убедиться, что новое оборудование подойдет и улучшит мой рабочий процесс.

-

Я устанавливаю четкие стандарты качества для каждого своего торта.

-

Я запланировал регулярную уборку и техническое обслуживание, чтобы поддерживать пекарню в безопасном и эффективном состоянии.

-

Я внимательно следил за своими расходами и искал способы уменьшить количество отходов.

-

Я поговорил со своей командой о наших целях и о том, как новая система поможет нам развиваться.

-

Я продолжал искать пути совершенствования, используя отзывы и новые идеи, чтобы сделать свою пекарню лучше.

Совет: Хороший план значительно облегчает переход к автоматизации. Я всегда записываю свои цели и шаги, чтобы иметь возможность отслеживать свой прогресс.

Установка

Когда прибыла моя линия по производству тортов, я хотел, чтобы установка прошла гладко. Я работал с поставщиком, чтобы установить каждую машину в нужном месте. Я убедился, что электропитание, водоснабжение и вентиляция готовы до того, как оборудование было доставлено. Мы с командой расчистили территорию и отметили, где будет стоять каждая деталь.

Вот как я справился с установкой:

-

Я проверил доставку и убедился, что все детали на месте.

-

Я следовал инструкциям поставщика по сборке и настройке.

-

Я проверял каждую машину, чтобы убедиться, что она работает, прежде чем переходить к следующему шагу.

-

Я работал с инженерами, чтобы подключить машины к системам моей пекарни.

-

Во время установки я поддерживал чистоту и безопасность.

-

Я попросил поставщика показать мне, как пользоваться органами управления и средствами безопасности.

Я убедился, что хорошо организованная установка сэкономила мне время и стресс. Мою пекарню не пришлось закрывать надолго, и я сразу же смог приступить к использованию нового оборудования.

Обучение

Обучение моей команды было ключом к тому, чтобы максимально эффективно использовать мою новую линию по производству тортов. Я хотела, чтобы все чувствовали себя уверенно и были готовы к работе с новым оборудованием. Я записалась на специализированные программы обучения от Американской ассоциации пекарей. На этих курсах мои сотрудники узнали, как смешивать, формировать, выпекать, охлаждать и упаковывать торты с помощью новой системы. Обучение проводилось по требованию, поэтому мои сотрудники могли учиться в удобном для них темпе.

Я также поощрял своих сотрудников зарабатывать сертификаты от таких организаций, как Американское общество пекарей и Ассоциация розничных пекарей. Эти сертификаты помогли моей команде научиться украшать торты, обращаться с оборудованием и обеспечивать безопасность пищевых продуктов. Некоторые из членов моей команды даже стали сертифицированными мастерами-пекарями, что повысило репутацию нашей пекарни.

-

Моя команда научилась точно соблюдать порядок действий на каждом этапе.

-

Мы практиковались в использовании средств контроля и проверке качества на каждом этапе.

-

Я следил за тем, чтобы все знали, как чистить и обслуживать машины.

-

Мы вместе изучили правила безопасности и передовой опыт.

Примечание: Инвестиции в обучение окупаются. Моя команда работает быстрее, допускает меньше ошибок и гордится своими навыками.

Тестирование

После установки новой системы и обучения команды я приступил к этапу тестирования. На этом этапе я убедился, что все работает правильно, прежде чем принимать крупные заказы. Я хотел, чтобы моя пекарня работала бесперебойно и доставляла Идеальные торты каждый раз. Вот как я тестировал и оптимизировал свое оборудование:

-

Я проверил каждую движущуюся деталь на плавность хода. Я использовал пищевую смазку для узла втулки циферблата. Этот шаг обеспечил бесшумную работу машины и помог пирожным переместиться в нужное положение.

-

Я осмотрел и очистил серводвигатели и лопасти. Я удалил старую смазку и все крошки или тесто, прилипшие к деталям. Чистые лезвия режут лучше и служат дольше.

-

Я откалибровал настройки резки. Я установил правильную скорость и давление для каждого типа торта. Я использовал панель управления для настройки ультразвукового резака. Я убедилась, что частота держится в диапазоне от 20 до 40 кГц. Эта настройка позволила получить острые, чистые срезы без сплющенных краев.

-

Я делал пробные партии и наблюдал за результатами. Я искал ровные ломтики и идеальные формы. Если возникали проблемы, я менял настройки и пробовал снова.

-

Я просмотрел данные о производительности системы. Я проверил, насколько быстро работает линия и сколько тортов прошло проверку. Я искал способы ускорить процесс и сократить количество отходов.

-

Я установил порядок регулярного технического обслуживания. Я и моя команда следовали контрольному списку для смазки, очистки, осмотра и калибровки. Мы делали это каждую неделю, чтобы поддерживать систему в идеальном состоянии.

Совет: Никогда не пропускайте этап тестирования. Тщательное тестирование и регулярные проверки помогут вам выявить мелкие проблемы до того, как они превратятся в крупные. Ваши торты будут лучше выглядеть и вкуснее, а оборудование прослужит дольше.

Тестирование придало мне уверенности. Я знал, что моя пекарня справится с любым заказом. Моя команда чувствовала себя готовой, а мои клиенты заметили разницу в качестве.

Преодоление трудностей

Бюджет

Я знаю, что покупка нового оборудования может показаться дорогой. Я сам столкнулся с этой проблемой. Я хотел развивать свою пекарню, но не хотел тратить слишком много денег сразу. Я нашел разумный способ решить эту проблему. Я начал с модульной системы. Это значит, что сначала я купил только те части, которые мне были нужны. Позже, по мере роста бизнеса, я добавлял новые машины. Некоторые поставщики предлагали полуавтоматические варианты. Они стоили дешевле, чем полностью автоматические линии. При этом они экономили мое время и трудозатраты. Я также искал варианты финансирования. Многие компании позволяли мне платить небольшими суммами каждый месяц. Это помогло мне управлять денежными потоками и инвестировать в будущее моей пекарни.

Совет: начните с малого и расширяйтесь по мере роста. Модульные и полуавтоматические системы обеспечивают гибкость без больших первоначальных затрат.

Космос

В моей пекарне не так много места. Приходилось учитывать каждый дюйм. I измерил кухню и спланировал планировку прежде чем что-то купить. Я убедился, что моя команда может достать ингредиенты и легко перемещаться от подготовки к выпечке. Я выбрал оборудование, которое вписывалось в мое пространство и не загораживало проходы. Я добавил полки и шкафы для хранения. Я использовал программу для планирования помещений, чтобы увидеть, как все будет размещаться. Иногда я обращалась за помощью к дизайнеру. Я выделила специальную зону для инвентаря. Это позволило легко отслеживать ингредиенты и поддерживать порядок.

-

Я измерил все оборудование и места для подготовки.

-

Я убедился, что хранилища и морозильные камеры вписываются в мой план.

-

Я создал зону инвентаризации с полками и холодильником.

Примечание: Тщательное планирование и продуманный дизайн помогают небольшим пекарням рационально использовать пространство. Вам не нужна огромная кухня, чтобы обеспечить бесперебойную работу.

Персонал

Моя команда поначалу нервничала из-за новых машин. Я хотел, чтобы все чувствовали себя готовыми и уверенными. I организовать обучение для всего персонала. Мы шаг за шагом учились пользоваться новым оборудованием. Я начала с простых заданий и добавляла новые по мере того, как мы становились лучше. Я убедился, что все знают, как чистить и ухаживать за машинами. Я также научил свою команду проверять наличие проблем и устранять мелкие неполадки. Мы регулярно проводили совещания, на которых обсуждали, что работает, а что нужно изменить. Я прислушивался к отзывам и вносил улучшения.

-

Я дал своей команде время учиться в своем собственном темпе.

-

Я сосредоточился на безопасности и хороших привычках.

-

Я призывал сотрудников делиться идеями и задавать вопросы.

Совет: Обучение и командная работа помогают всем адаптироваться. Когда сотрудники чувствуют поддержку, они работают лучше и получают больше удовольствия от своей работы.

Истории успеха

Расширение

Моя пекарня сильно выросла с тех пор, как я приобрел новое оборудование. Другие пекарни тоже рассказали мне свои истории. Их успех заставляет меня стремиться к лучшему.

-

Пекарня A оснащена автоматизированными миксерами и печами. Они быстрее выполняли заказы и делали клиентов счастливыми. Их бизнес рос, потому что они могли выполнять больше работы.

-

Пекарня B показала новые торты в социальных сетях. Они прислушались к пожеланиям клиентов и добавили новые вкусы. С каждой неделей их торты покупали все больше людей.

Я также слышал о компании по производству тортов в Дакке, Бангладеш. Они хотели, чтобы у них было больше клиентов как дома, так и в других странах. Они начали использовать систему управления HACCP. Это помогало им делать более безопасные и качественные торты. Их бизнес рос, и они начали продавать торты в новые места. Я вижу, что хорошие системы и разумное планирование помогают пекарням расти.

Совет: Если вы хотите развиваться, работайте над эффективностью и создавайте качественные торты. Прислушивайтесь к своим клиентам и используйте новые инструменты, чтобы охватить больше людей.

Последовательность

Мои клиенты хотят, чтобы каждый торт был вкусным и красиво выглядел. Другие пекари чувствуют то же самое. Когда я разговариваю с владельцами пекарен, они говорят, что улучшение оборудования изменило их результаты.

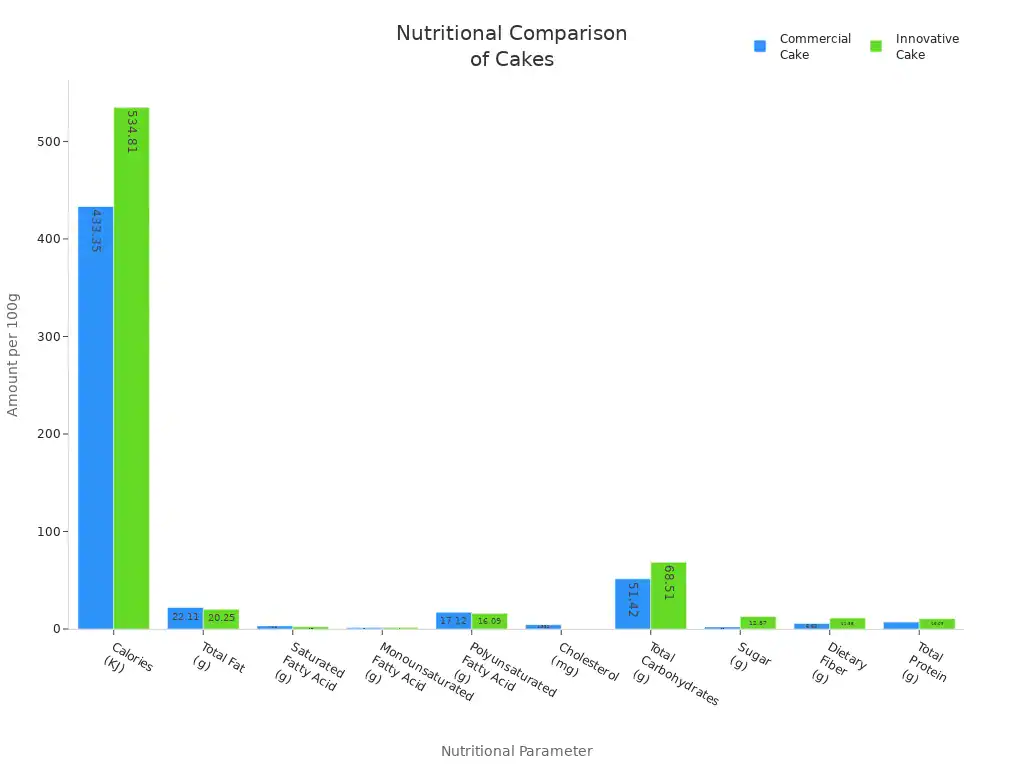

Позвольте мне показать вам, что произошло, когда пекарни получили новые производственные линии:

|

Питательный параметр |

Коммерческий торт (на 100 г) |

Инновационный торт (на 100 г) |

|---|---|---|

|

Калории (кДж) |

534.81 |

|

|

Общее количество жира (г) |

22.11 |

20.25 |

|

Насыщенная жирная кислота (г) |

3.20 |

2.35 |

|

Мононенасыщенная жирная кислота (г) |

1.34 |

1.44 |

|

Полиненасыщенная жирная кислота (г) |

17.12 |

16.09 |

|

Холестерин (мг) |

4.35 |

0.00 |

|

Общее количество углеводов (г) |

51.42 |

68.51 |

|

Сахар (г) |

2.10 |

12.87 |

|

Диетическая клетчатка (г) |

5.65 |

11.35 |

|

Общий белок (г) |

7.17 |

10.63 |

|

Витамин |

Коммерческий торт (на 100 г) |

Инновационный торт (на 100 г) |

|---|---|---|

|

Витамин А (мкг) |

853.11 |

1038.24 |

|

Тиамин (витамин B-1) (мг) |

0.13 |

0.82 |

|

Рибофлавин (витамин B-2) (мг) |

0.14 |

0.54 |

|

Витамин С (мг) |

0.11 |

0.27 |

|

Ниацин (витамин B-3) (мг) |

0.91 |

2.08 |

|

Витамин Е (мг) |

0.73 |

1.03 |

Я вижу, что новые системы помогают пекарям делать торты с лучшей питательностью и вкусом. Торты каждый раз получаются одинаковыми. Клиенты замечают и больше доверяют пекарне. Я думаю, что использование лучших инструментов дает лучшие результаты.

Примечание: Постоянство в работе укрепляет доверие. Когда каждый торт получается великолепным, клиенты возвращаются и рассказывают о нем своим друзьям.

Максимизация инвестиций

Техническое обслуживание

Я хочу, чтобы моя линия по производству тортов прослужила долго. Я хочу, чтобы она работала хорошо каждый день. Я составил план для регулярное обслуживание. Это позволяет поддерживать бесперебойную работу. Моя команда чистит и проверяет машины во время смены продукции. Мы не тратим лишнее время. Линия быстро готовится к выпуску следующей партии. Мы используем контрольный список для очистки, смазки и проверки деталей. Моя команда ищет изношенные детали и меняет их раньше.

Я также заключил договор на обслуживание с поставщиком. Договор предусматривает регулярное техническое обслуживание и глубокую очистку. В него также входят тесты, чтобы убедиться, что все работает. Я не беспокоюсь о внезапных поломках. Мой поставщик помогает поддерживать линию в хорошем состоянии. Хорошо обслуживаемая система означает меньше проблем. Это также означает, что мы можем делать больше тортов.

Совет: Всегда соблюдайте график технического обслуживания. Чистите и проверяйте машины во время смены продукции. Это сэкономит деньги и позволит вашей пекарне работать вовремя.

Обновления

Я всегда ищу способы помочь своей пекарне развиваться. Модернизация линии по производству тортов помогает мне быть впереди. Я начал с добавления новых модулей, когда мне понадобилось больше места. У моего поставщика были лучшие миксеры, более быстрые конвейеры и более умные упаковочные машины. Я выбрал те обновления, которые соответствовали моим целям и бюджету.

Вот несколько способов, с помощью которых я улучшил свою систему:

-

Я добавила новое оборудование для замеса и обработки теста, чтобы делать больше тортов.

-

Я модернизировала свои станции для макияжа и коррекции, чтобы расширить выбор продуктов.

-

Я установил новую систему охлаждения и транспортировки, чтобы работать быстрее.

-

Я усовершенствовал свои упаковочные машины, чтобы торты выглядели красивее.

-

Для изучения новых функций я использовал удаленную поддержку и обучение у своего поставщика.

Я также попробовал новые идеи, такие как Серия APEX и Пилотная пекарня Пуратоса. Это позволило мне опробовать новые рецепты и приготовить больше тортов, не меняя всего. Мой поставщик предоставил мне запасные части, планы обслуживания и инструкции. Мне было легко вносить изменения, потому что мне помогали специалисты.

Примечание: Вам не нужно начинать все сначала, чтобы обновить линию по производству тортов. Вы можете добавлять новые функции и развиваться шаг за шагом. Это позволит вашей пекарне быть готовой к будущему и защитит ваши инвестиции.

Я видел, как моя пекарня преображается с появлением линии по производству тортов. Я выполнил следующие действия чтобы добиться наилучших результатов:

-

Я использовал автоматизацию для повышения эффективности и точности.

-

Я довел до автоматизма смешивание, наполнение, нарезку и украшение.

-

Я следил за выпечкой с помощью интеллектуальных датчиков.

-

Я организовал контроль качества и гигиенические проверки.

-

Я обновлял свою систему шаг за шагом.

-

Я разработал индивидуальные решения для своей пекарни.

-

Я освободил свою команду для творческой работы.

-

Автоматизация помогла мне сократить расходы и повысить качество.

-

Я выполняла больше заказов и делала клиентов счастливыми.

-

Теперь моя пекарня выделяется новыми продуктами и стабильным ростом.

Сделайте следующий шаг. Обновите свою пекарню линией по производству тортов и наблюдайте за процветанием своего бизнеса!

Часто задаваемые вопросы

Как узнать, нужна ли моей пекарне линия по производству тортов?

Я смотрю на объем заказов и загруженность персонала. Если я вижу, что производство идет медленно или заказы не выполняются, я понимаю, что время пришло. Линия по производству тортов помогает мне развиваться и обслуживать больше клиентов без лишнего стресса.

Могу ли я начать с малого и позже расширить свою линию по производству тортов?

Да! Я начал с базовой установки. По мере роста бизнеса я добавлял новые машины. Модульные системы позволяют мне модернизировать оборудование шаг за шагом. Таким образом, я контролирую свой бюджет и увеличиваю масштаб, когда буду готов.

Трудно ли обучать персонал работе с новым оборудованием?

Нет, это не сложно. Я использую обучение поставщиков и простые руководства. Моя команда быстро учится, применяя практические навыки. После обучения я вижу лучшие результаты и более счастливых сотрудников.

Какие виды тортов можно приготовить с помощью производственной линии?

Я готовлю классические торты, кексы, мраморные торты и кексы с начинкой. Система позволяет мне легко менять рецепты и формы. Моим клиентам нравится разнообразие. Я даже могу пробовать новые вкусы каждую неделю!

Как содержать линию по производству тортов в чистоте и безопасности?

Я соблюдаю график уборки. Мои машины имеют легко очищаемые детали. Я использую безопасные для пищевых продуктов чистящие средства и слежу за износом. Мой поставщик дает мне советы для достижения наилучших результатов. Чистое оборудование обеспечивает сохранность и свежесть моих тортов.

Сэкономит ли линия по производству тортов мои деньги?

Да! Я трачу меньше труда и отходов. Машины эффективно используют ингредиенты. Я выполняю больше заказов, не нанимая дополнительных сотрудников. Моя прибыль растет по мере снижения затрат.

Что делать, если у меня небольшая пекарня с ограниченным пространством?

Я измеряю свое пространство и выбираю компактные машины. Некоторые системы подходят для узких помещений и при этом обеспечивают высокую производительность. Я использую полки и продуманную планировку, чтобы каждый дюйм был на счету.

Совет: Обратитесь к поставщику за консультацией по планировке. Они помогут вам вписать производственную линию практически в любую пекарню.

Цзюньюй Линия по производству тортов